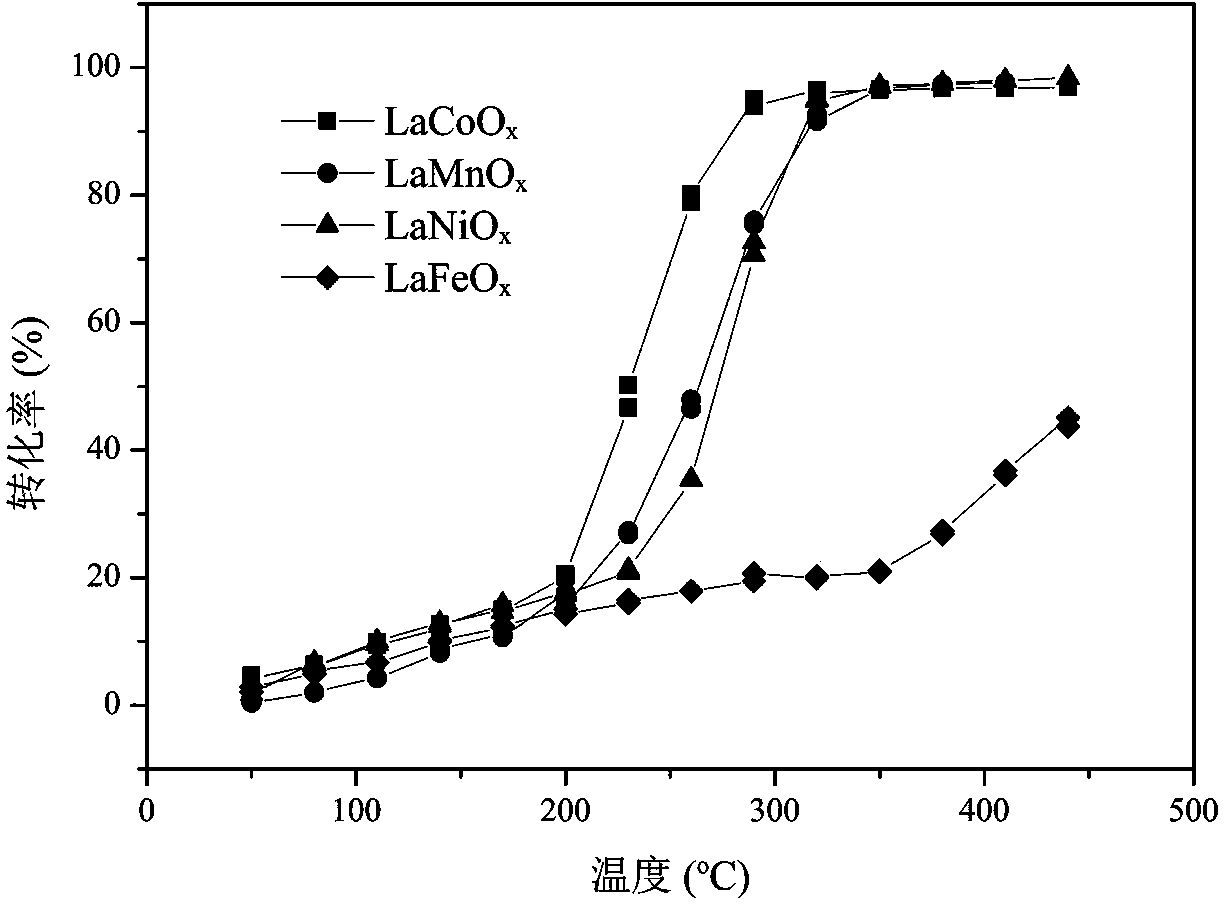

High-activity lanthanum and cobalt composite oxide catalyst, preparation and application

A composite oxide and catalyst technology, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve photochemical smog pollution, toxicity, human health and ecology Environmental impact and other issues, to achieve high catalytic oxidation activity, simple preparation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] At room temperature, the La(NO 3 ) 3 , Co(NO 3 ) 2 , And 3 times the mole of metal ion citric acid dissolved in absolute ethanol. Under stirring conditions, add HF solution dropwise until the solution turns into a gel. 120 o C dry, 300 o C roasting for 3 h.

Embodiment 2

[0018] At room temperature, the La(NO 3 ) 3 , Co(NO 3 ) 2 , And 3 times the mole of metal ion citric acid dissolved in absolute ethanol. Under stirring conditions, add HF solution dropwise until the solution turns into a gel. 120 o C dry, 300 o C roasting for 3 h.

Embodiment 3

[0020] At room temperature, the La(NO 3 ) 3 , Co(NO 3 ) 2 , And 3 times the mole of metal ion citric acid dissolved in absolute ethanol. Under stirring conditions, add HF solution dropwise until the solution turns into a gel. 120 o C dry, 300 o C roasting for 3 h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com