Preparation method of bagasse pith-based modified polysaccharide-loaded palladium nanoparticle catalyst

A palladium nano-catalyst technology is applied in the field of preparation of a sucrose base-modified polysaccharide-supported palladium nano-particle catalyst, which can solve the problems of low selectivity of the palladium catalyst, and achieve the effects of practicable principle, simple process operation, and environmentally friendly process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

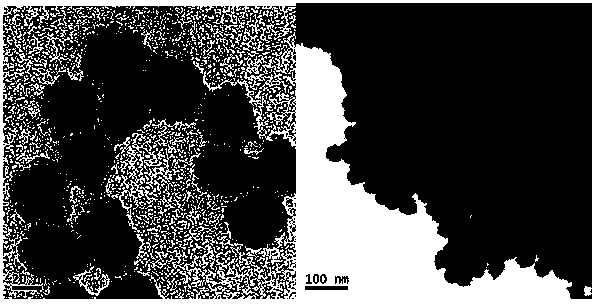

Image

Examples

Embodiment 1

[0026] A preparation method for a sucrose-based modified polysaccharide-loaded palladium nanoparticle catalyst for catalyzing the semihydrogenation of acetylene, comprising the following steps:

[0027] (1) The preparation method of sugarcane pith polysaccharide is as follows: add 20.0 g of sugarcane pith into 400 mL of 9% sodium hydroxide solution as a solvent, react in a water bath at 25 °C for 30 min at 300 rpm, and add the extract to into dehydrated ethanol, the volume ratio of the extract to dehydrated ethanol is 1:9, set aside for precipitation, filter, and freeze-dry for 48 hours to obtain sucrose pith polysaccharide solid;

[0028] Preparation of polysaccharide-based porous carrier: Take 1.0g sucrose polysaccharide and add it to a flask filled with 10mL of 4% sodium hydroxide solution, heat to 60°C to dissolve, cool to room temperature, add 0.05g potassium peroxodisulfate and 0.05g sodium thiosulfate (as a redox initiator), stirred for about 15min to initiate free radi...

Embodiment 2

[0033] A preparation method for a sucrose-based modified polysaccharide-loaded palladium nanoparticle catalyst for catalyzing the semihydrogenation of acetylene, comprising the following steps:

[0034] (1) The preparation method of sugarcane pith polysaccharide is as follows: add 20.0 g of sugarcane pith into 400 mL of 9% sodium hydroxide solution as a solvent, react in a water bath at 25 °C for 30 min at 300 rpm, and add the extract to into dehydrated ethanol, the volume ratio of the extract to dehydrated ethanol is 1:9, set aside for precipitation, filter, and freeze-dry for 48 hours to obtain sucrose pith polysaccharide solid;

[0035] Preparation of polysaccharide-based porous carrier: Take 1.0g sucrose polysaccharide and add it to a flask filled with 10mL of 4% sodium hydroxide solution, heat to 60°C to dissolve, cool to room temperature, add 0.06g potassium peroxodisulfate and 0.06g sodium thiosulfate (as a redox initiator), stirred for about 12min to initiate free radi...

Embodiment 3

[0040] A preparation method for a sucrose-based modified polysaccharide-loaded palladium nanoparticle catalyst for catalyzing the semihydrogenation of acetylene, comprising the following steps:

[0041] (1) The preparation method of sugarcane pith polysaccharide is as follows: add 20.0 g of sugarcane pith into 400 mL of 9% sodium hydroxide solution as a solvent, react in a water bath at 25 °C for 30 min at 300 rpm, and add the extract to into dehydrated ethanol, the volume ratio of the extract to dehydrated ethanol is 1:9, set aside for precipitation, filter, and freeze-dry for 48 hours to obtain sucrose pith polysaccharide solid;

[0042] Preparation of polysaccharide-based porous carrier: Take 1.0g sucrose polysaccharide and add it to a flask filled with 15mL of 4% sodium hydroxide solution, heat to 60°C to dissolve, cool to room temperature, add 0.06g potassium peroxodisulfate and 0.05g sodium thiosulfate (as a redox trigger), stirred for about 15min to trigger free radical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com