Method for preparing carbon disulfide from carbon oxygen compound as raw materai

A carbon oxide and carbon disulfide technology, applied in the direction of carbon disulfide, carbon sulfur compounds, etc., can solve the problems of low sulfur conversion rate, low conversion rate of carbonyl sulfide disproportionation process, and low separation efficiency of carbonyl sulfide and carbon dioxide.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but not limited to the embodiments.

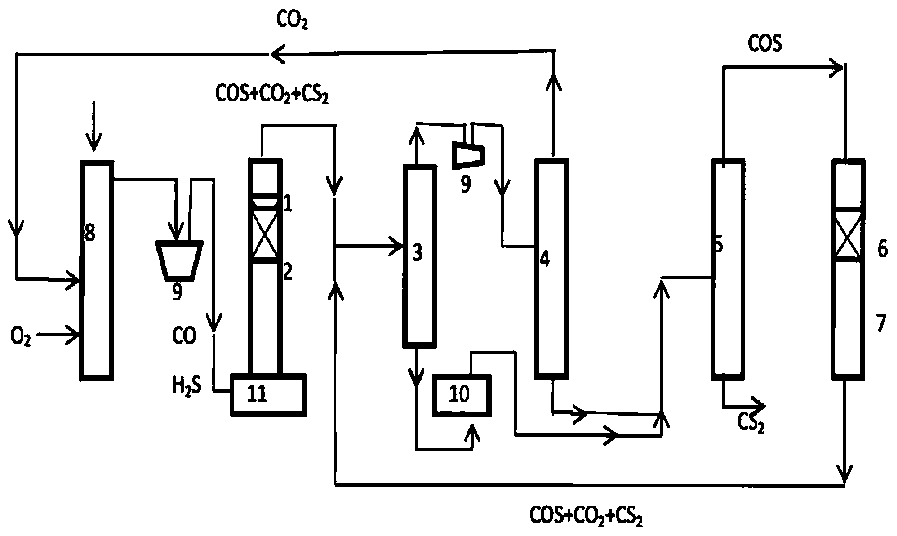

[0023] A kind of carbon oxides as raw materials to prepare CS 2 The method, at first in carbon monoxide generator 8, take coke as raw material, oxygen and carbon dioxide as gasifying agent to prepare raw material gas carbon monoxide, described carbon dioxide is the carbon dioxide separated in above-mentioned step c, then comprise the following steps: a. After the carbon monoxide and hydrogen sulfide are pressurized by the gas compressor 9, a uniform mixture of CO and hydrogen sulfide is obtained, and then introduced into the carbonyl sulfide synthesis tower equipped with a metal sulfide COS low-temperature synthesis catalyst to generate carbonyl sulfide and make part of the carbonyl sulfide Disproportionation is decomposed into carbon disulfide and carbon dioxide; the molar ratio of carbon monoxide to hydroge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com