Pipe cutting device

A technology of pipe cutting device and punching device, applied in the direction of pipe shearing device, shearing device, shearing machine equipment, etc., can solve the problems of slow cutting speed, waste of resources, large burr in the incision, etc., achieve a reasonable and practical overall structure, improve smoothness degree, reduce the effect of burr

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

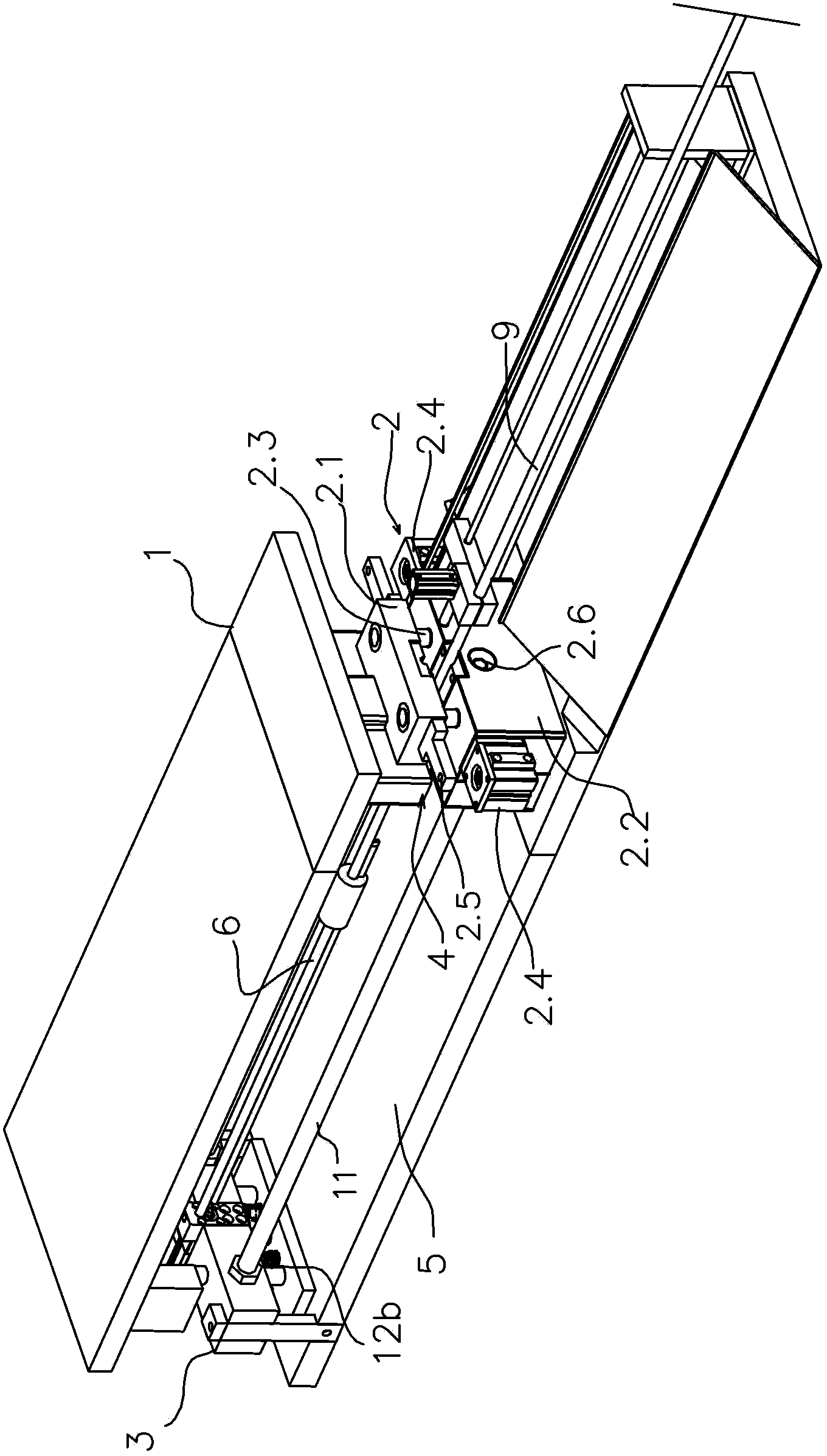

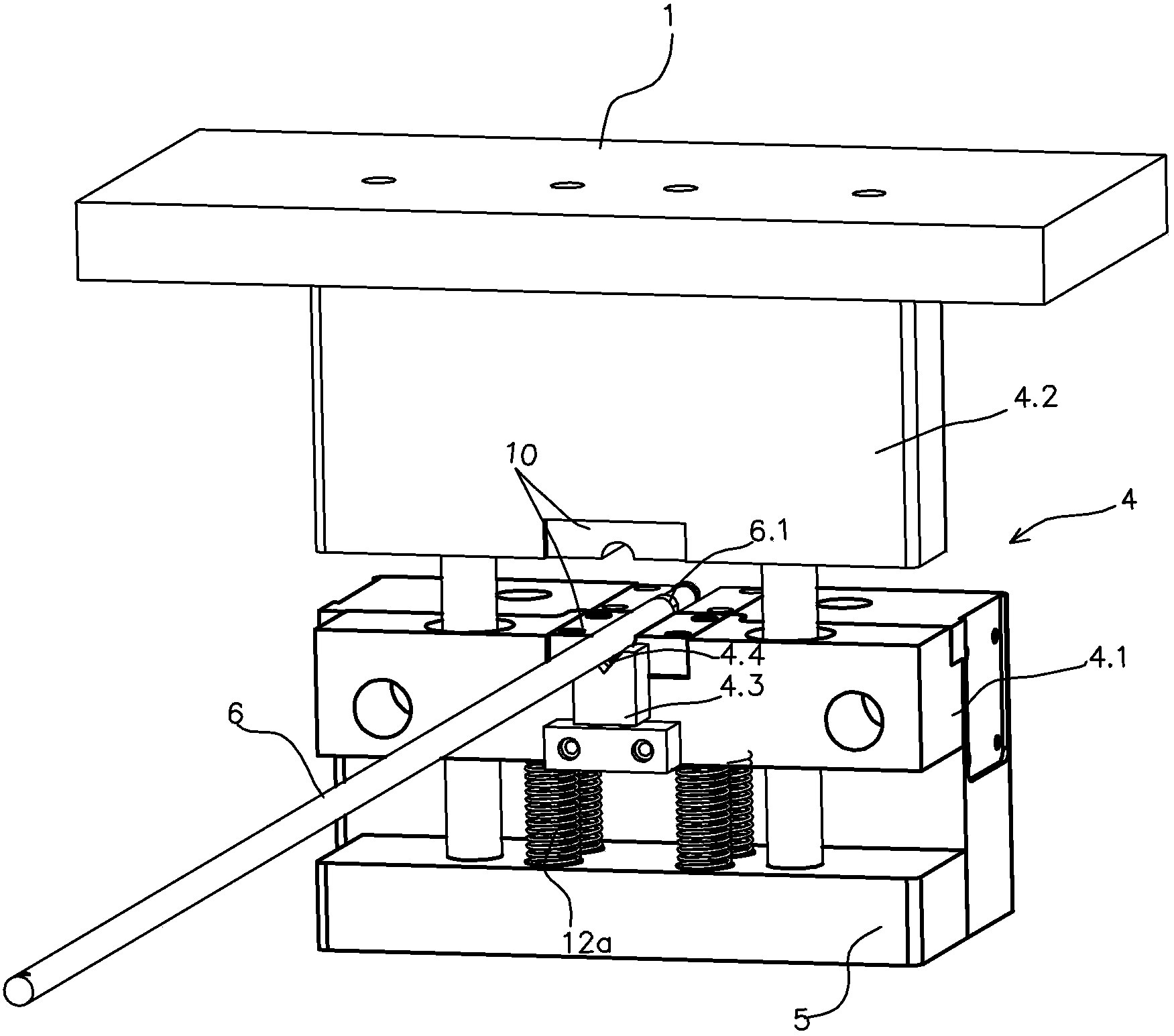

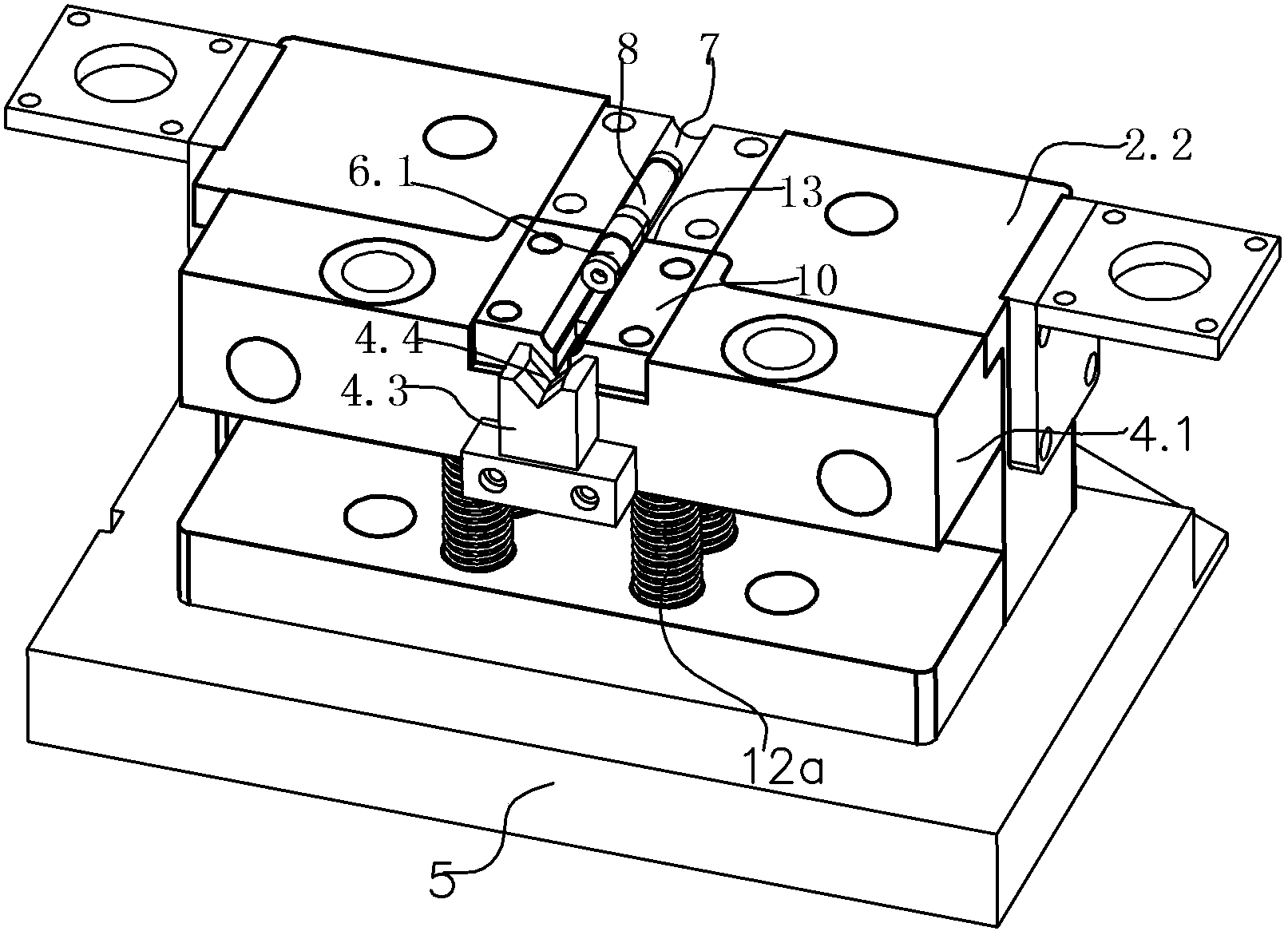

[0029] Such as Figure 1-3 As shown, a high-precision pipe cutting device includes main components such as an upper mold fixing plate 1, a clamping mold base 2, a mandrel fixing frame 3, and a pipe cutting mechanism 4; wherein:

[0030] The upper mold fixed plate 1 is connected with a stamping device, and the upper mold fixed plate 1 can be pressed down and raised rapidly under the action of the stamping device.

[0031] A clamping mold base 2 is fixed on the base 5, and the clamping mold base 2 includes two parts, an upper clamping mold 2.1 and a lower clamping mold 2.2, which can be separated. Two guide pillars 2.3 are installed on the lower clamping mold 2.2. 2.1 is sleeved on the guide post 2.3 and can slide up and down along the guide post 2.3. In order to realize the clutch between the upper clamping die 2.1 and the lower clamping die ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap