Nail-cutting wood drill

A woodworking drill and nail cutting technology, which is applied to woodworking appliances, wood drilling tools, wood turning tools, etc., can solve the problems of unusable woodworking drills, decreased drilling quality and efficiency, weak blade strength and hardness, etc. Achieve the effect of increased strength, good hardenability and good comprehensive cutting performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

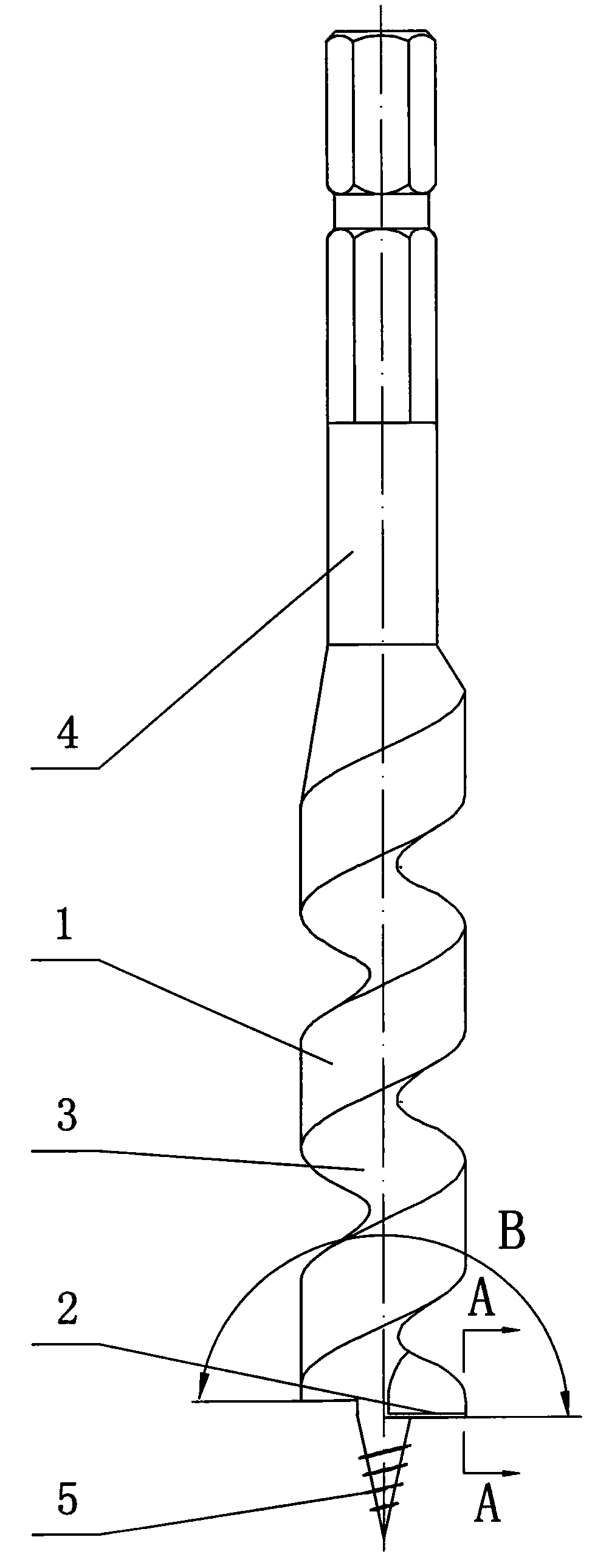

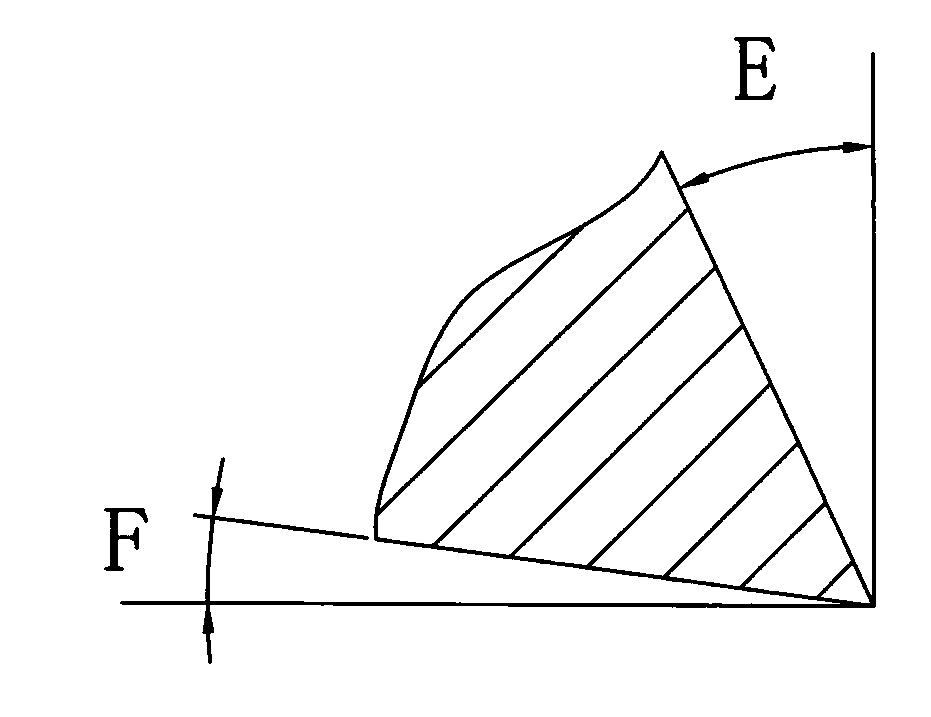

[0012] figure 1 , figure 2 It is a schematic diagram of the structure of a nail-cutting woodworking drill. It can be seen from the figure that it includes a drill body 1, the front end of the drill body 1 is a cutting edge 2, a spiral chip removal groove 3 is formed on the drill body 1, and a clamp for clamping is formed at the tail end of the drill body 1. The drill shank 4, the front end of the center of the drill body 1 is formed with a conical screw tip 5, the apex angle B of the cutting edge 2 is 180 degrees, the rake angle E of the main cutting edge at the outer edge is 30-25 degrees, and the rear angle F is 8-10 degrees. The material of the nail-cutting woodworking drill is made of GCr15 material. The hardness of the cutting edge 2 is HRC56-52.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com