Electric vehicle transmission system

A transmission system and electric vehicle technology, which is applied to vehicle components, control devices, transportation and packaging, etc., can solve the problems of transmission system running stability, long vibration force arm of power system, large center distance of reducer, etc., and achieve uniformity Good loading effect, stable high-speed operation, and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

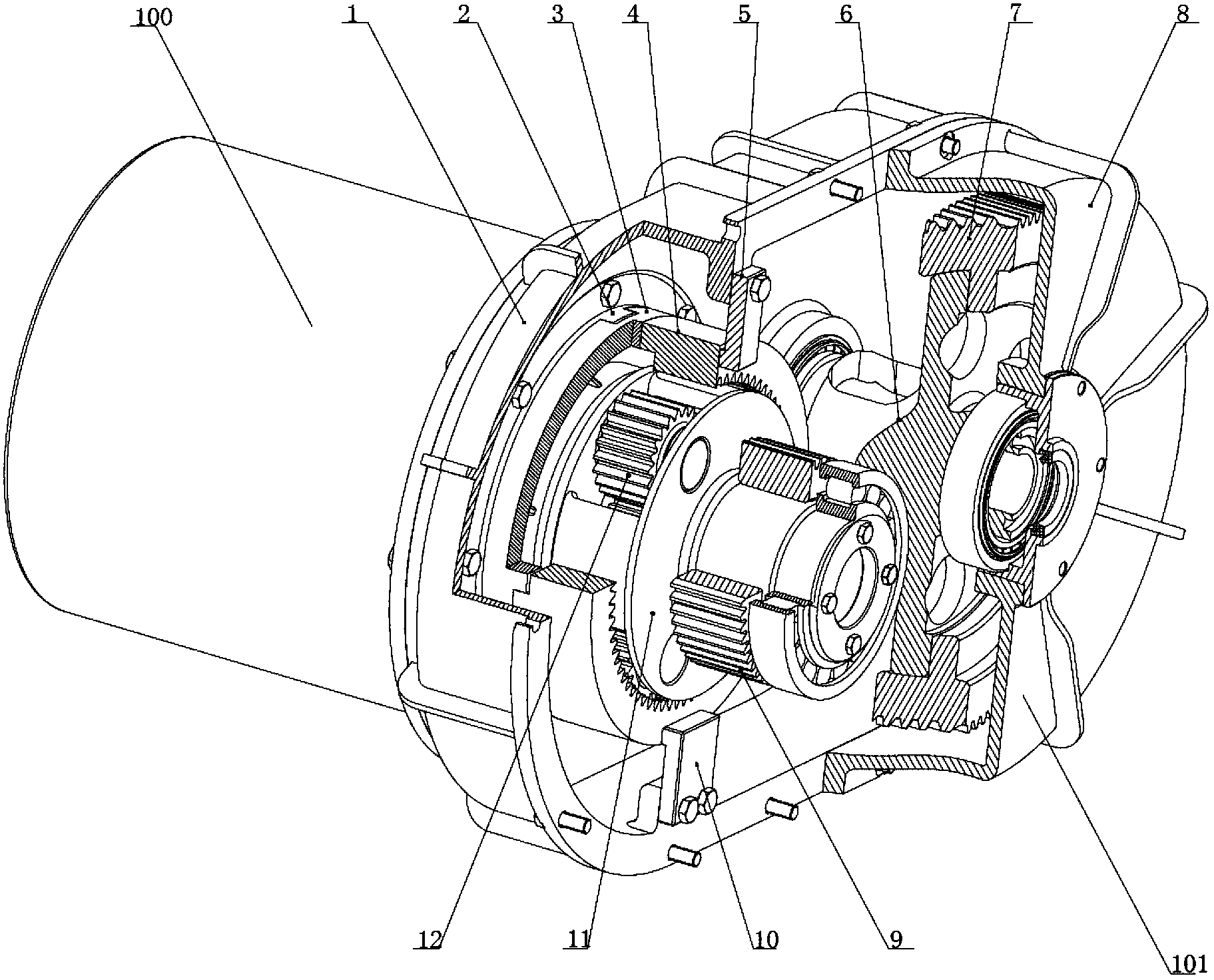

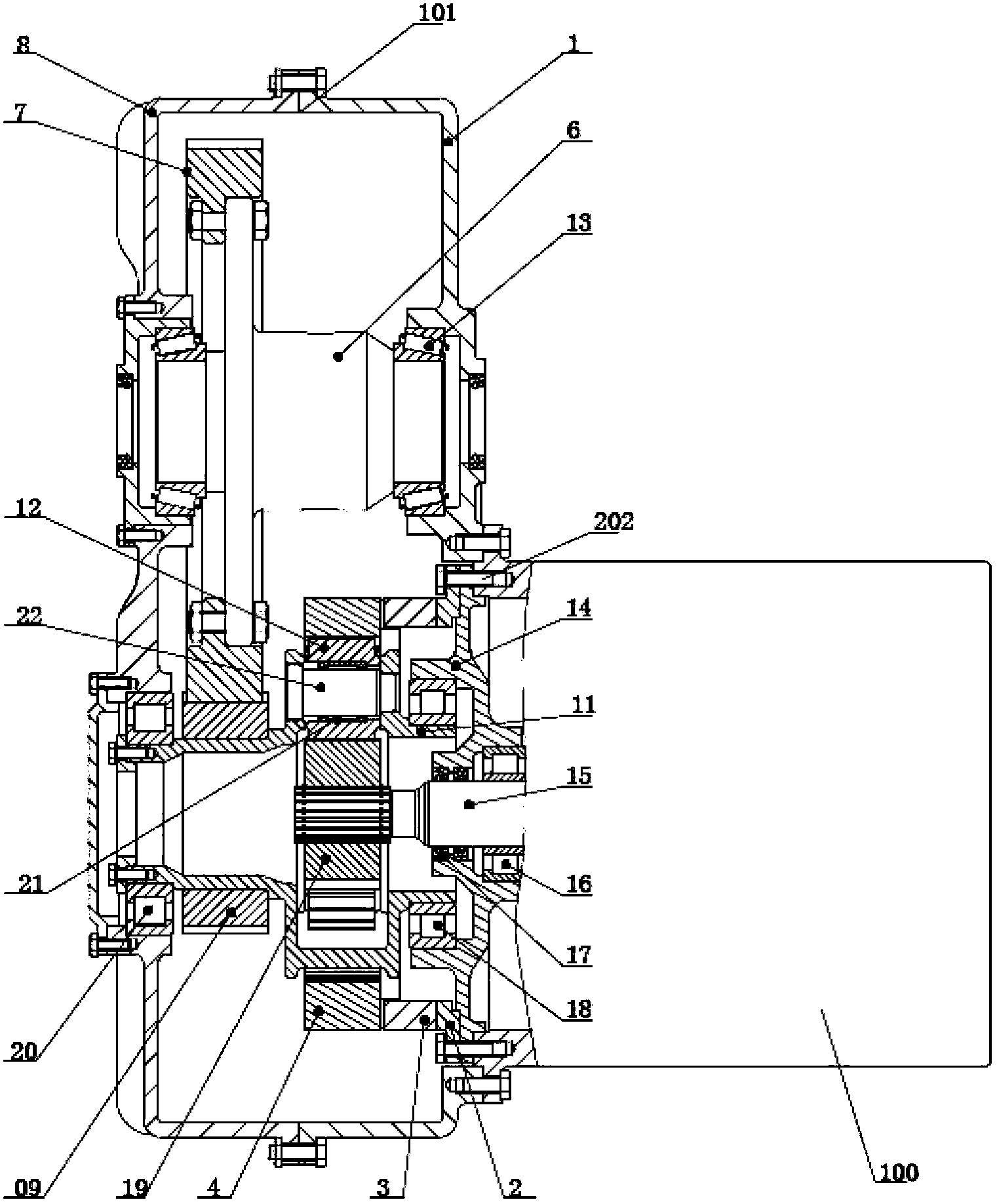

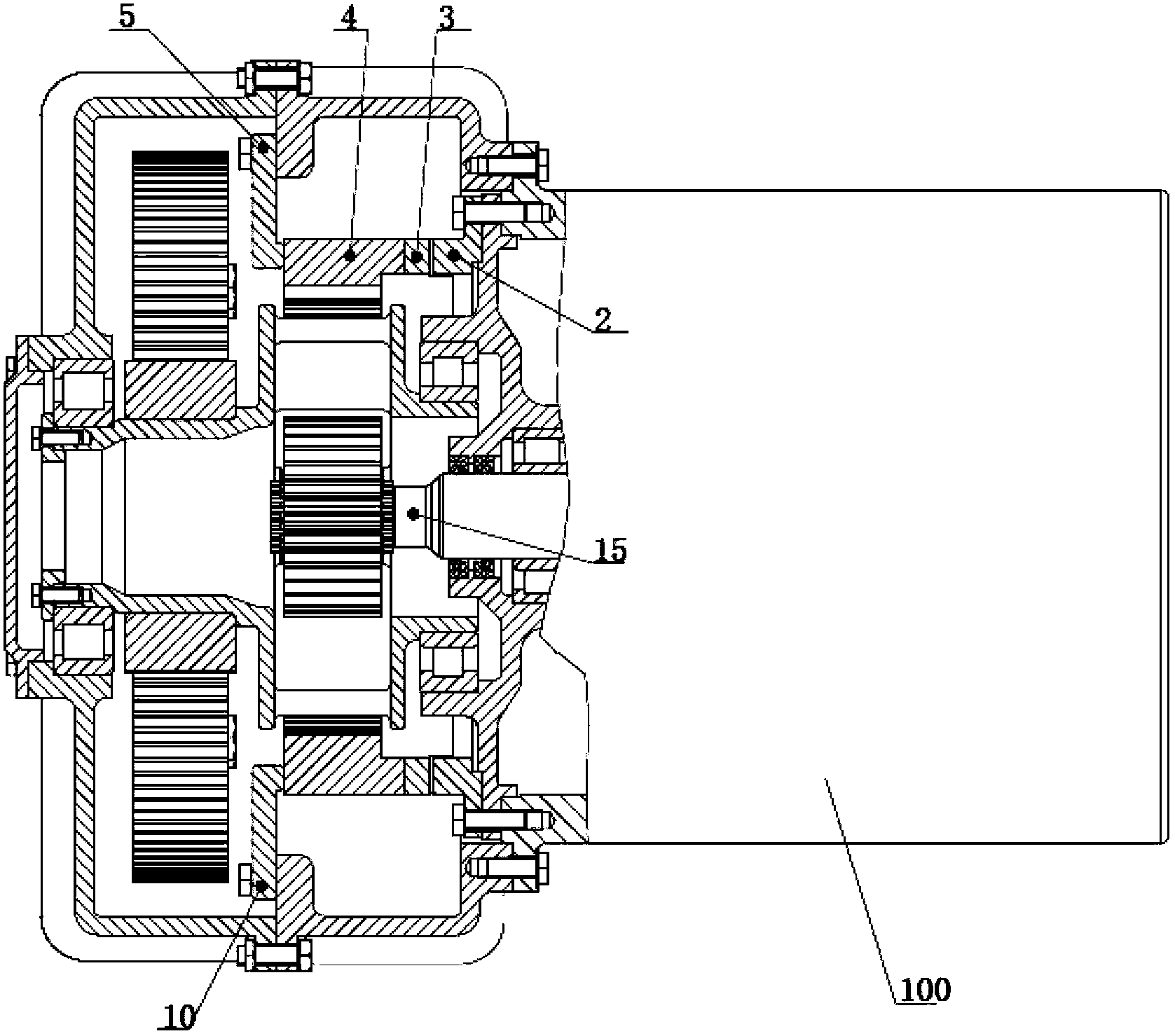

[0021] like figure 1 , the specific embodiment of the present invention provides an electric vehicle transmission system used in a pure electric vehicle, which includes a motor 100 and a reducer 101 integrated with the motor 100 . The casing of the reducer 101 is fixedly connected to the motor 100, specifically the end of the motor 100, that is, the casing can be directly connected to the motor 100 and at the same time constitute the end cover of the motor 100, or can be connected to the end cover of the motor 100 The motor 100 is fixedly connected indirectly, and it can also be connected to the end of the motor 100 and the end cover of the motor 100 is housed in the reducer 101 as a whole. In this specific embodiment, the casing of the reducer 101 is connected to the casing of the motor 100 through bolts, and the end cover 14 of the motor is accommodated in the reducer 101 .

[0022] Continue to refer to figure 1 , the reducer 101 adopts a vertical box structure, and the bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com