Full-automatic battery changing system for electric vehicles

An electric vehicle and battery replacement technology, which is applied to electric power units, power units, vehicle components, etc., can solve the problems of increasing labor costs, heavy weight of a single battery, and reducing battery replacement efficiency, and achieves the effect of reliable positioning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

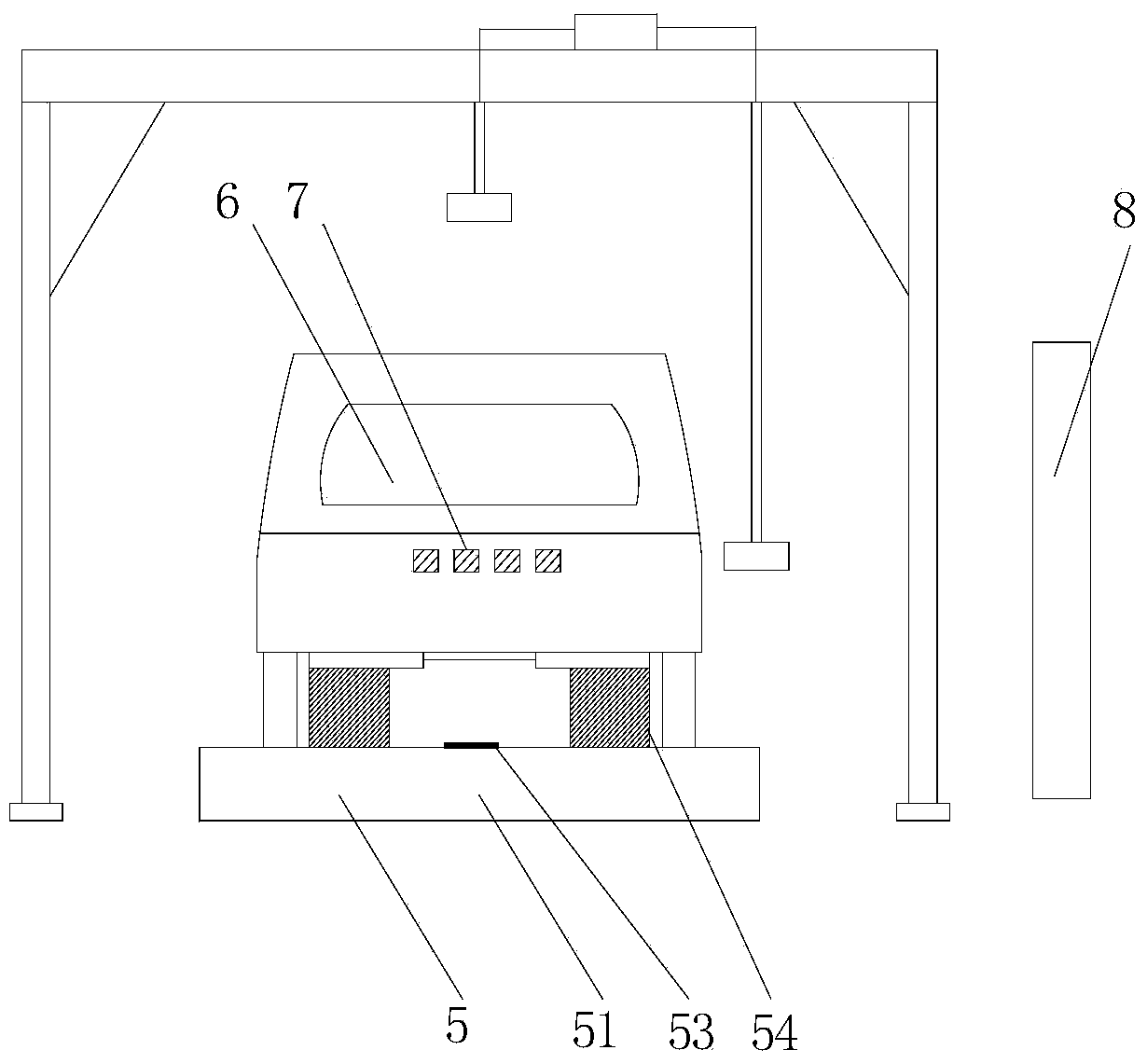

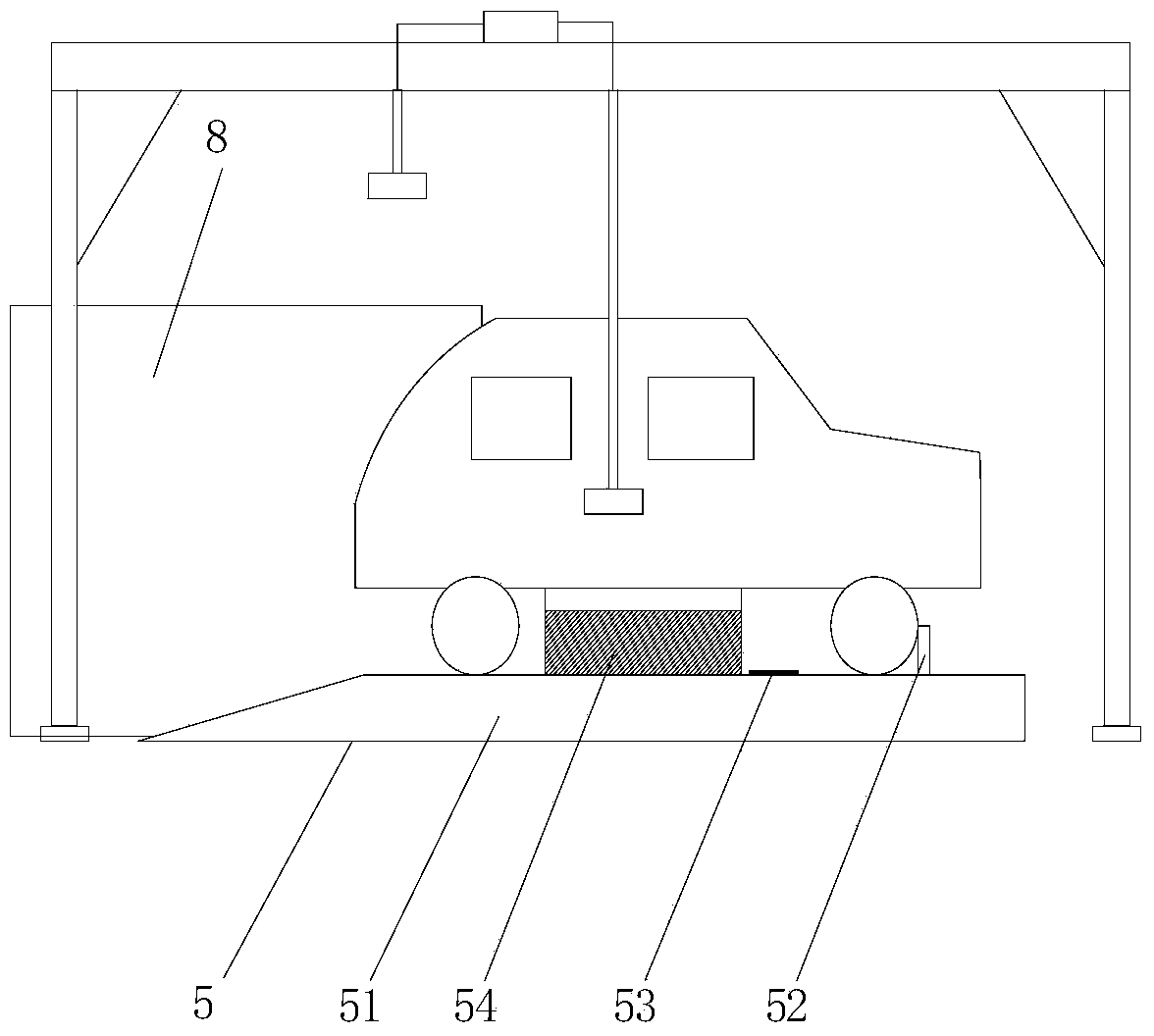

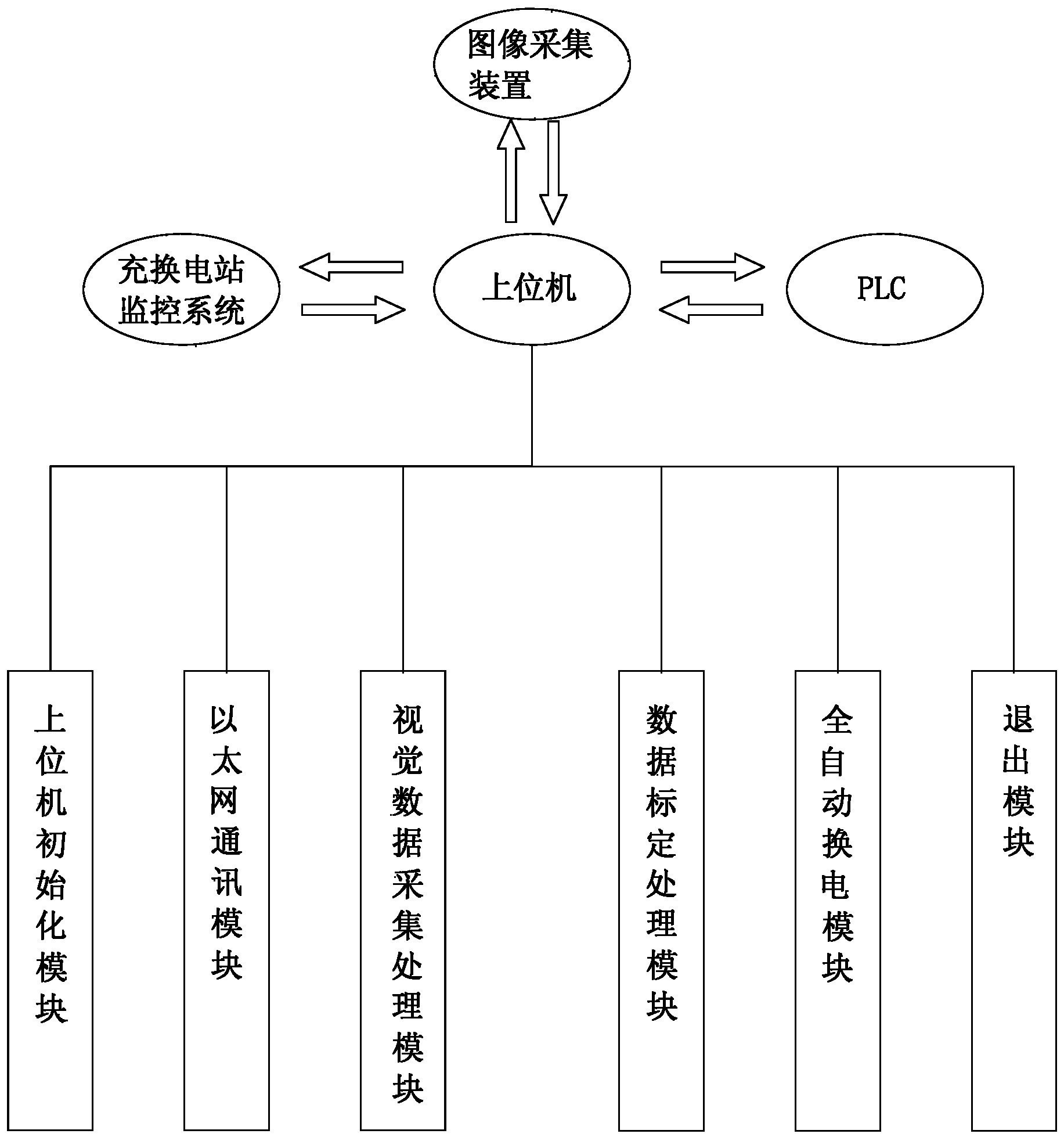

[0073] The invention provides a fully automatic battery replacement system for an electric vehicle, which is composed of a control system, a positioning platform, an execution system and a battery compartment 7 for storing batteries.

[0074] The positioning platform will be used to locate the electric vehicle driving into the swap station; the control system will obtain information on the completion of the positioning of the electric vehicle and send the information to the execution system; the execution system will be used to perform the work of replacing the battery of the electric vehicle.

[0075] Wherein, the positioning platform 5 includes a bottom plate 51 fixedly arranged on the ground and a front baffle 52 arranged on the bottom plate 51 for restricting the front and rear positions of the electric vehicle;

[0076] It also includes an electronic measuring rule 53 arranged on the bottom plate 51 for measuring the distance between the chassis of the electric vehicle and the up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com