Direction changing device and transferring device

A direction conversion, horizontal direction technology, applied in conveyors, mechanical conveyors, transportation and packaging, etc., can solve problems such as difficulty in adjustment, and achieve the effect of miniaturization and improved safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

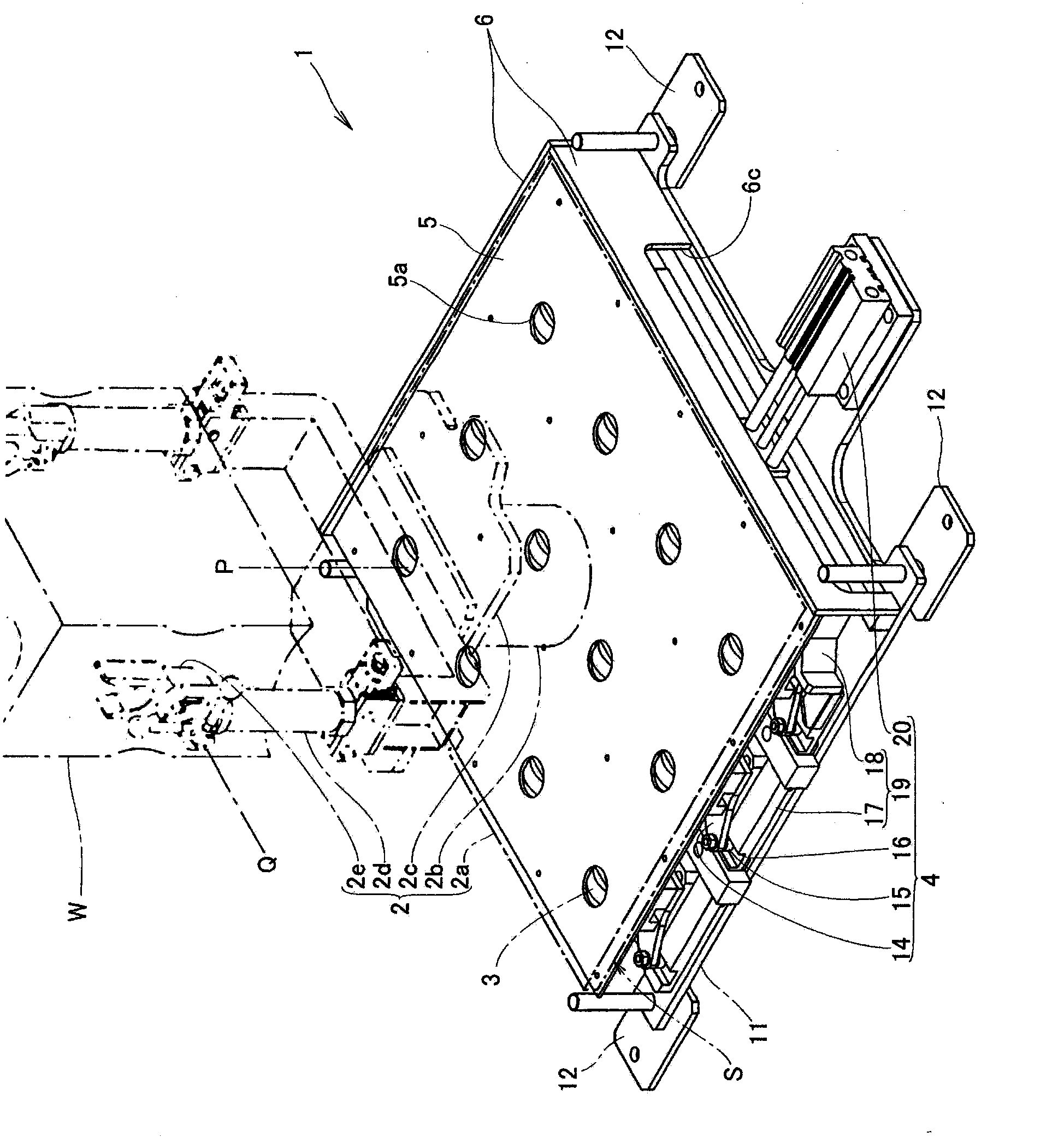

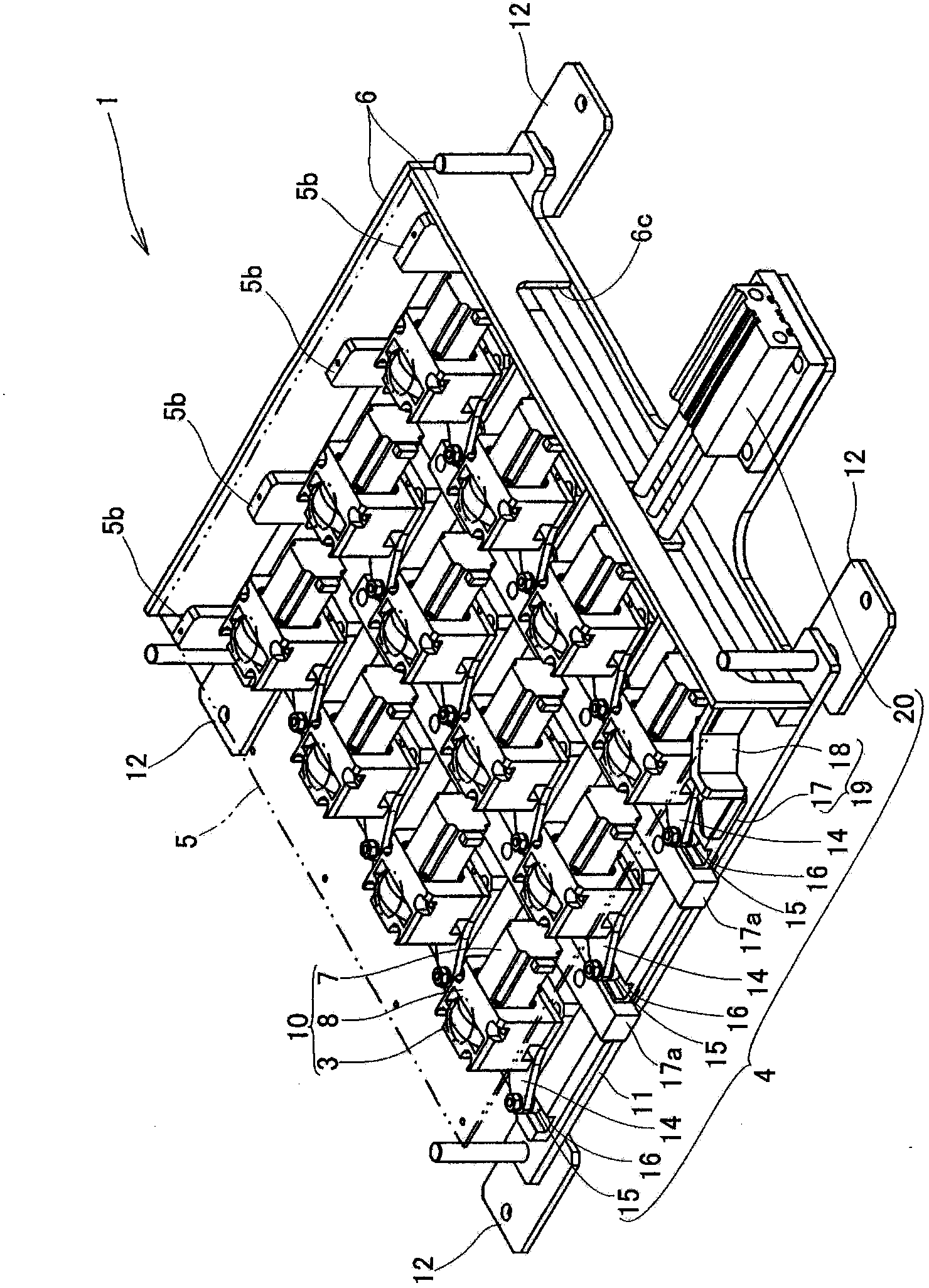

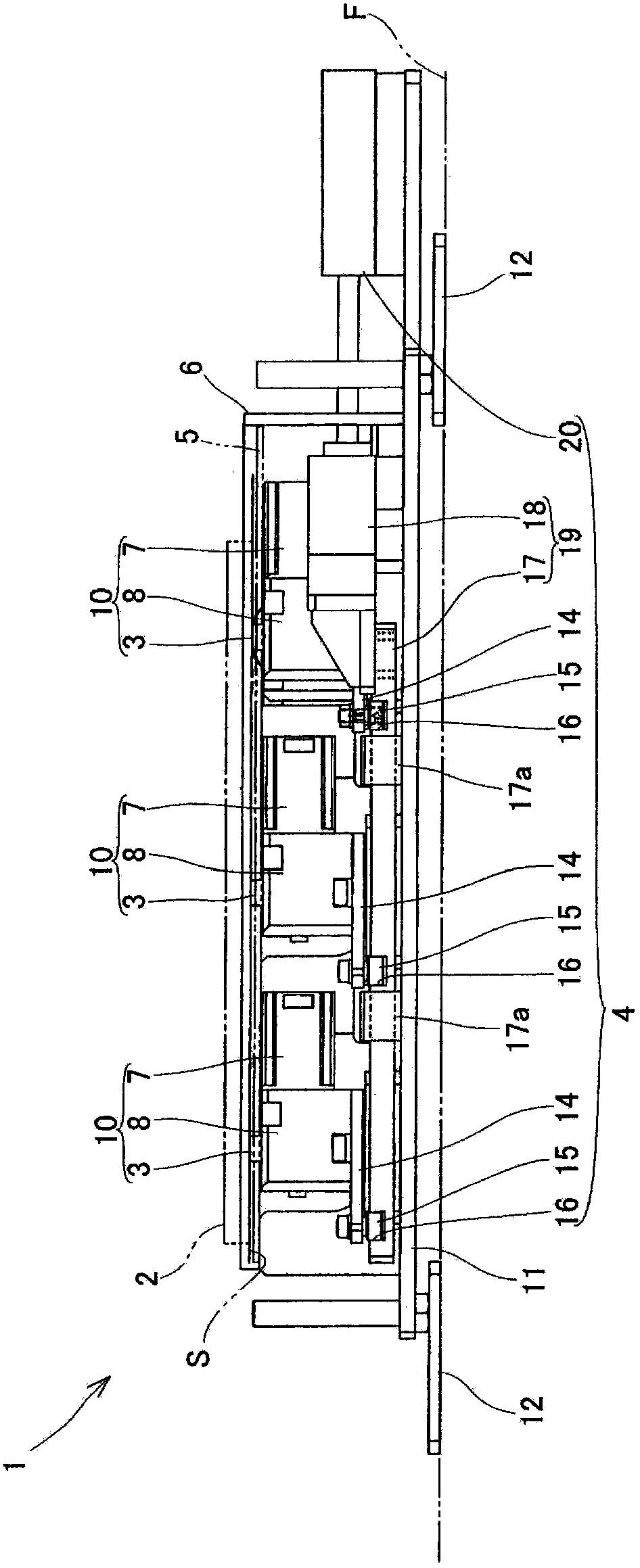

[0051] Figure 1 to Figure 7 It shows the direction changing device 1 according to the first embodiment of the present invention that rotates the roller unit by 90° by using an air cylinder to move the cam follower provided on the turning mechanism back and forth when turning the roller unit. Structure diagram. Such as figure 1 As shown, the direction changing device 1 of the present invention includes: a plurality of rollers 3 arranged along a two-dimensional direction substantially parallel to the conveying surface S, and abutting against the lower surface of the pallet 2 (transported object) on which workpieces W such as engines are mounted. Surface; Rotary mechanism 4, makes the rotating shaft of each roller 3 rotate around the vertical axis simultaneously; The top surface cover 5 of plan view approximately square shape, is parallel with conveying surface and is formed with through-hole 5a at the position of described each roller 3; And guide plate 6. Installed on the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com