Method and system for adjusting mass and torque of a spool rotor in a wave power plant

A wave power generation and rotor technology, applied in general control systems, control/regulation systems, mechanical equipment, etc., can solve problems such as expensive, complex adjustment equipment, torque fluctuation mode, etc., to improve output performance and working capacity, high output performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

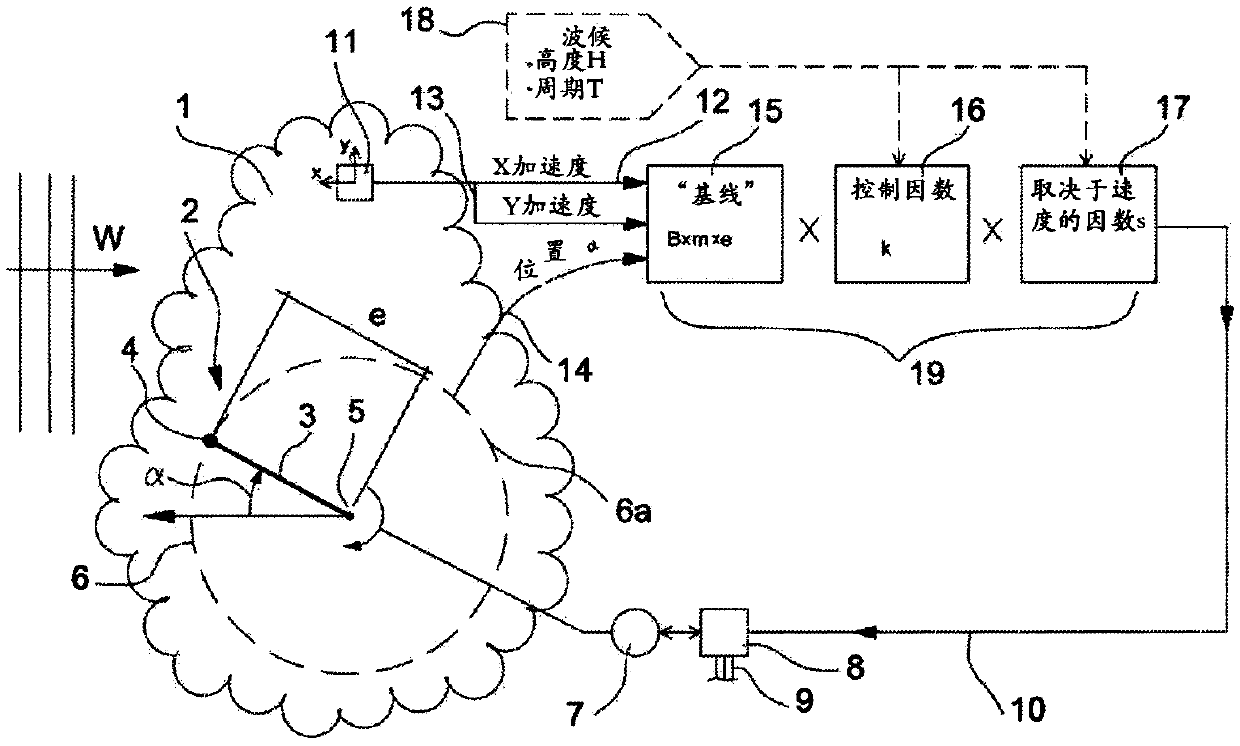

[0040] exist figure 1 A preferred implementation of the adjustment system of the invention is shown in a schematic diagram in FIG. The rotor 2 and the buoyant body 1 may be of any known type in construction, for example of the type described in the above-cited application. These do not form the object of the present invention and are not discussed further.

[0041] The vertical dimension of the submerged part of the floating body 1 is usually larger than the horizontal dimension of the section. Preferably, more than 80% of the height of the buoy is submerged, and the buoy 1 is dimensioned to extend in the vertical direction to a depth where substantial wave motion exists. The floating body 1 floats on the water and is moored in such a way that when the floating body contacts the wave front W, the floating body swings back and forth or performs a gyrating motion.

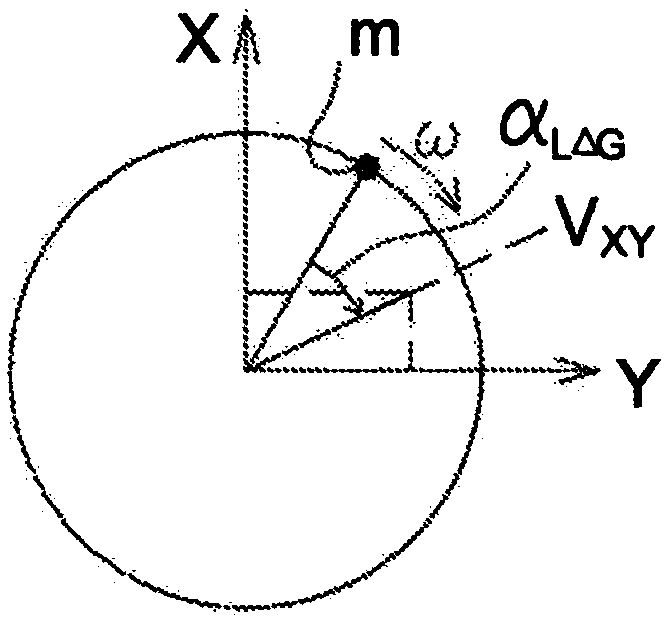

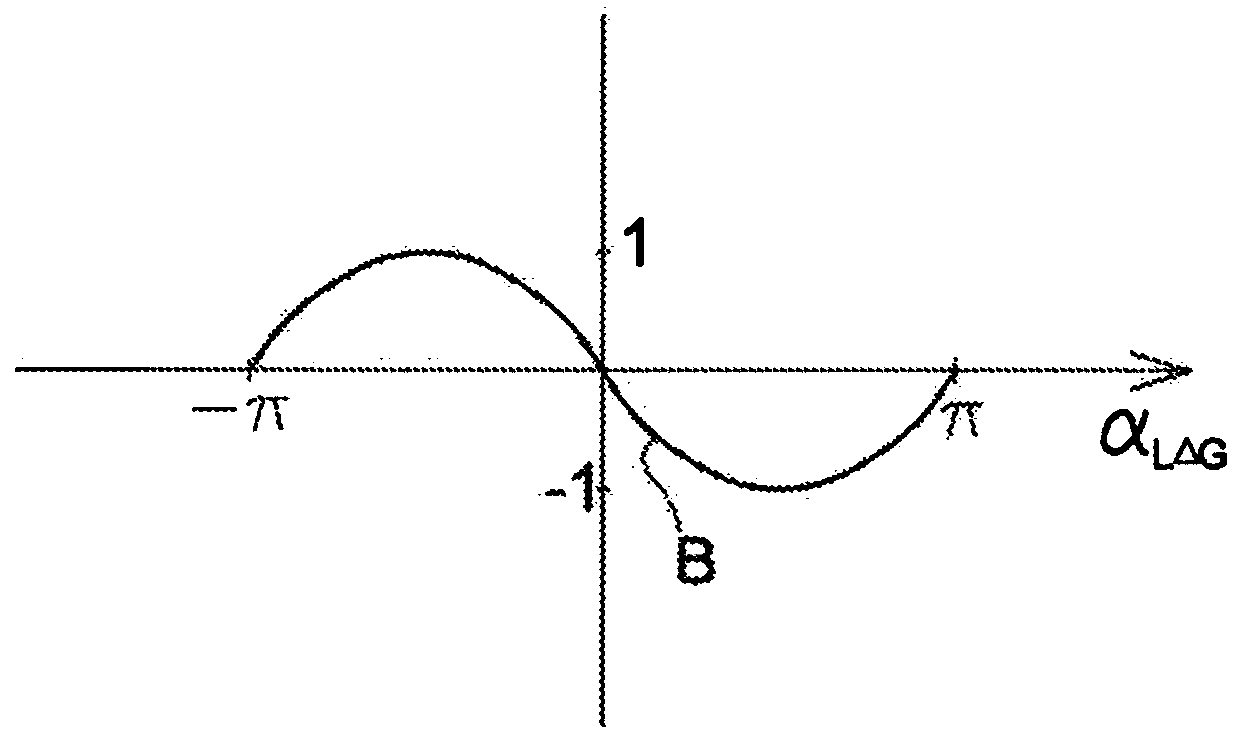

[0042] The rotor 2 is supported on a floating body for rotation about a vertical axis 5 . The rotor comprises ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com