Gridding vortex street reactor

A reactor and grid technology, applied in the direction of flocculation/sedimentation water/sewage treatment, etc., can solve the problems of poor flocculation effect, large eddy current, etc., and achieve the effects of easy installation, enhanced efficiency, and full use of pool capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

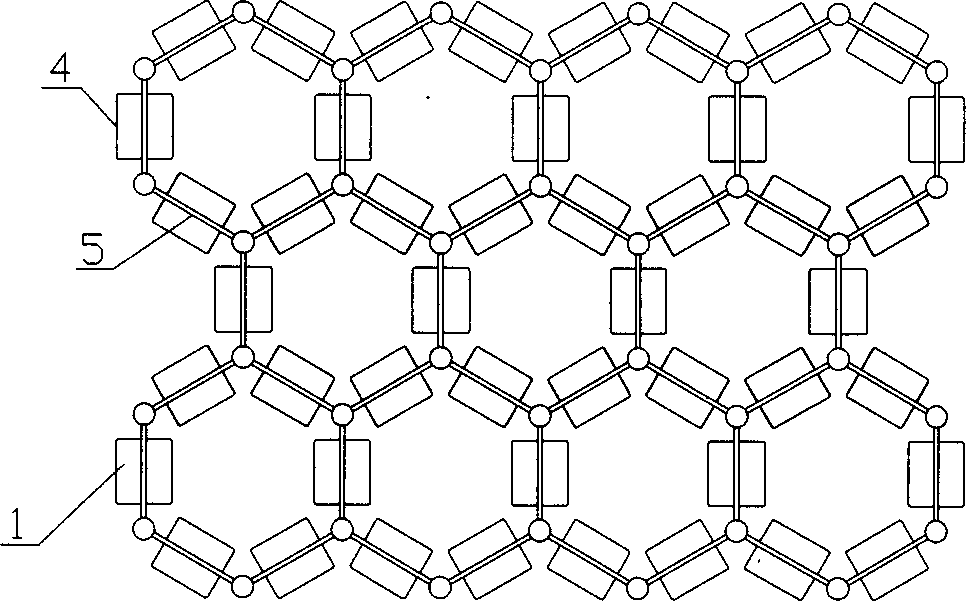

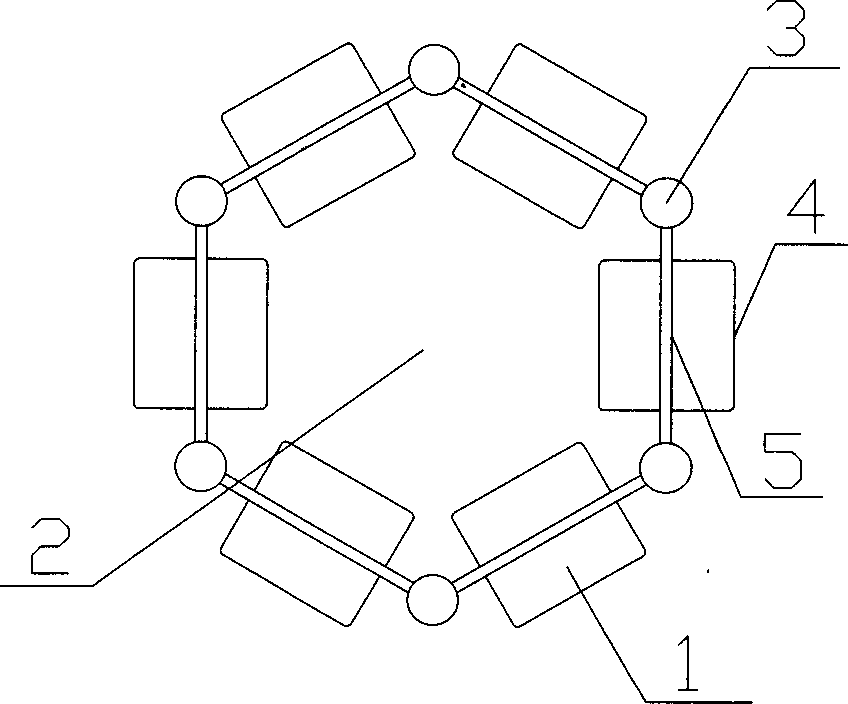

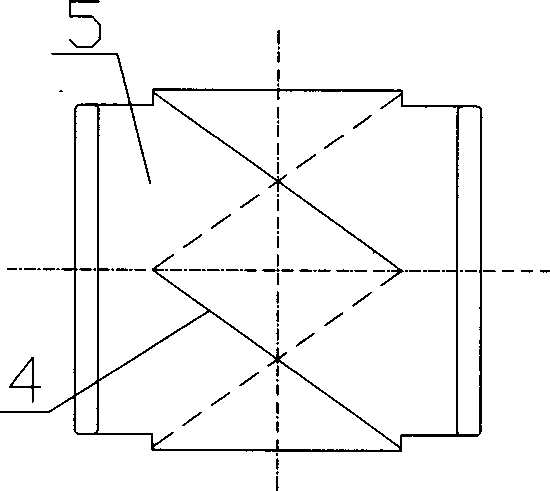

[0022] Such as figure 1 , figure 2 and image 3 As shown, the grid vortex street reactor is assembled from several grid units 2 as a whole, and the grid unit 2 adopts a hollow structure, and is a hexagon assembled from horizontal diagonally corrugated grid strips 1 and connectors 3. The vertical height is 3cm-10cm. There are intersecting inclined corrugated boards 4 on both sides of the horizontal inclined corrugated board grid bar 1. The inclined corrugated boards 4 and the vertical flat board grid bars 5 are injection molded at one time. The angle between the crossed inclined corrugated boards 4 and the horizontal axis is 20°-60°. When the raw water mixed with chemicals passes through the grid unit 2 in the grid vortex street reactor, the direction of the water flow is further adjusted under the action of the slanted plate 4, which prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com