Method for preparing coal mine paste filling aggregate by using urban building waste as raw material

A technology for urban construction waste and construction waste, which is applied in the field of coal mine paste filling and mining, can solve the problems of limited consumption and high quality requirements, and achieve the effects of particle gradation optimization, pollution avoidance, and manpower and material saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

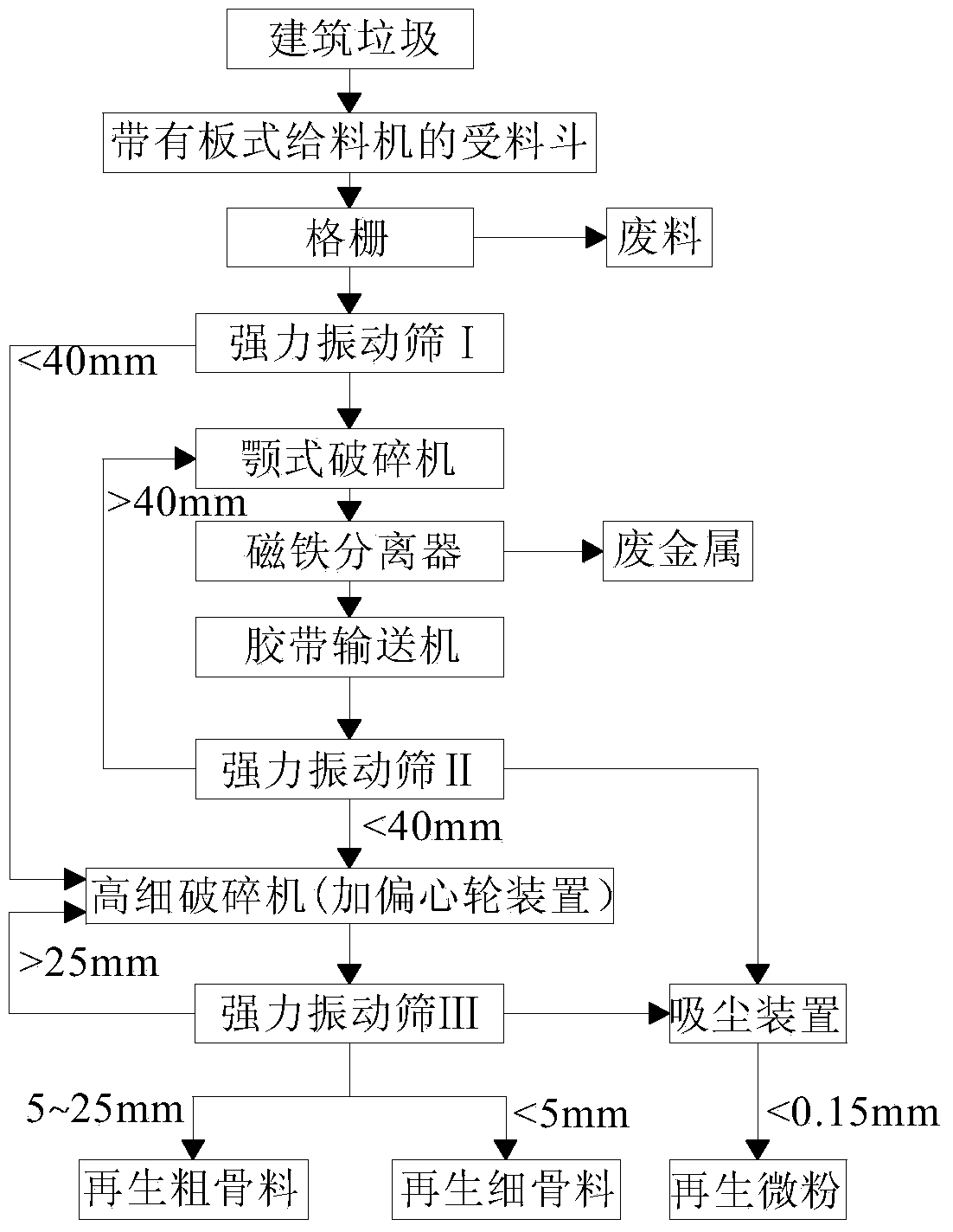

[0022] Such as figure 1 As shown, a method for preparing coal mine paste filling aggregate with urban construction waste as raw material is carried out in the following steps:

[0023] (1) Recycle construction waste and effectively classify it into frame concrete, brick concrete, asphalt concrete, and concrete with more impurities such as mortar. The first collection is carried out, and then sent to the receiving hopper with apron feeder, and the construction waste is screened through the grid equipment during the conveying process to remove the waste.

[0024] (2) Use the powerful vibrating screen I to screen the construction waste screened in step (1), send the construction waste with a particle size less than 40mm directly to the high-fine crusher, and send the construction waste with a particle size equal to or greater than 40mm to into the jaw crusher for crushing. The crushed construction waste is transported to the powerful vibrating screen II for screening by the bel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com