Method for preparing L-pyroglutamic acid

A technology of pyroglutamic acid and pyroglutamic acid ethanol, applied in the direction of organic chemistry and the like, can solve the problems of unsuitable industrial production, difficult removal of other impurities, complicated preparation process, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

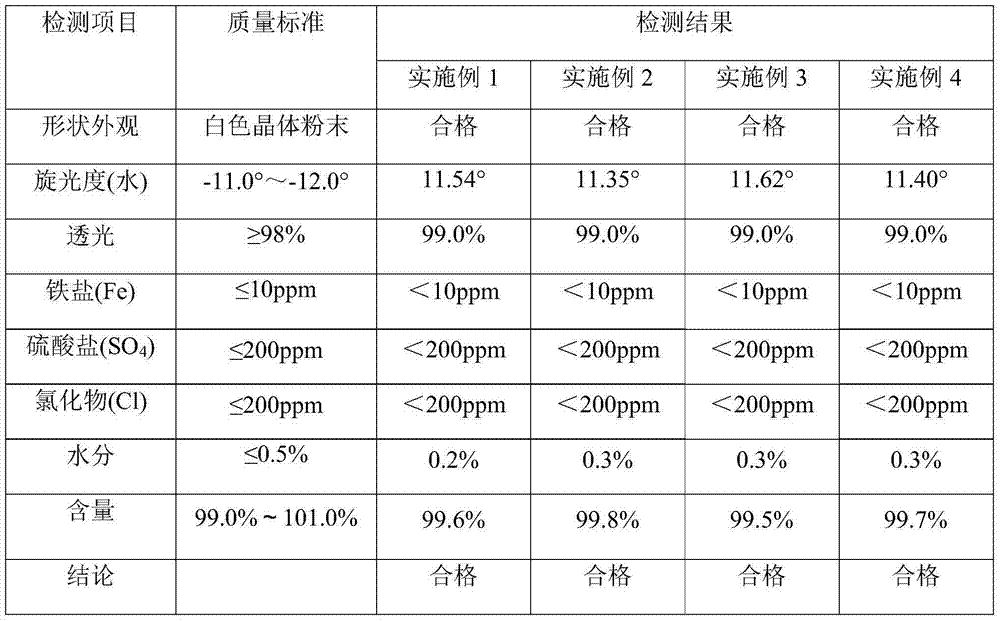

Embodiment 1

[0018] A method for preparing L-pyroglutamic acid, including: adding 147g of L-glutamic acid, 500ml of absolute ethanol, 2ml of concentrated sulfuric acid into a 1000L three-necked flask, heating to 90℃, and maintaining at 90℃ for 4 hours. Dehydration reaction. After the reaction, the reaction solution is filtered while it is hot. The ethanol filtrate of L-pyroglutamate is concentrated under reduced pressure at a temperature of 55°C to saturation. The ethanol concentrate of L-pyroglutamate is cooled to 20°C, and a large amount of crystals are precipitated. The L-pyroglutamic acid crystals were filtered out and dried at a temperature of 55°C to obtain 115 g of L-pyroglutamic acid refined product with a yield of 89.1%.

Embodiment 2

[0020] A method for preparing L-pyroglutamic acid, including: adding 294g of L-glutamic acid, 1200ml of absolute ethanol, 2ml of concentrated sulfuric acid into a 2000L three-necked flask, heating to 92°C, and maintaining at 92°C for 5 hours. Dehydration reaction. After the reaction, the reaction solution is filtered while it is hot. The ethanol filtrate of L-pyroglutamate is concentrated under reduced pressure at a temperature of 60°C to saturation. The ethanol concentrate of L-pyroglutamate is cooled to 20°C, and a large amount of crystals are precipitated. The L-pyroglutamic acid crystals were filtered out and dried at a temperature of 60°C to obtain 233 g of L-pyroglutamic acid refined product, with a yield of 90.3%.

Embodiment 3

[0022] A method for preparing L-pyroglutamic acid, including: adding 221g of L-glutamic acid, 900ml of absolute ethanol, 2.3ml of concentrated sulfuric acid into a 2000L three-necked flask, heating to 95°C, and maintaining at 95°C for 3 hours The dehydration reaction is carried out. After the reaction is completed, the reaction solution is filtered while it is hot. The ethanol filtrate of L-pyroglutamate is concentrated under reduced pressure to saturation at a temperature of 55°C. The ethanol concentrate of L-pyroglutamate is cooled to 25°C and a large amount of crystals are precipitated. The L-pyroglutamic acid crystals were filtered out with suction, and dried at a temperature of 55°C to obtain 175g of L-pyroglutamic acid refined product, with a yield of 90.2%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com