Marine diesel engine lubricating anti-rust oil composition and application thereof

A marine diesel engine, lubrication and anti-rust technology, applied in the direction of lubricating composition, petroleum industry, additives, etc., can solve the problems of poor anti-rust performance, lack of lubricating and anti-rust oil composition for marine diesel engines, mismatch, etc., to improve anti-rust performance , good anti-oxidation stability, keep clean effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~9

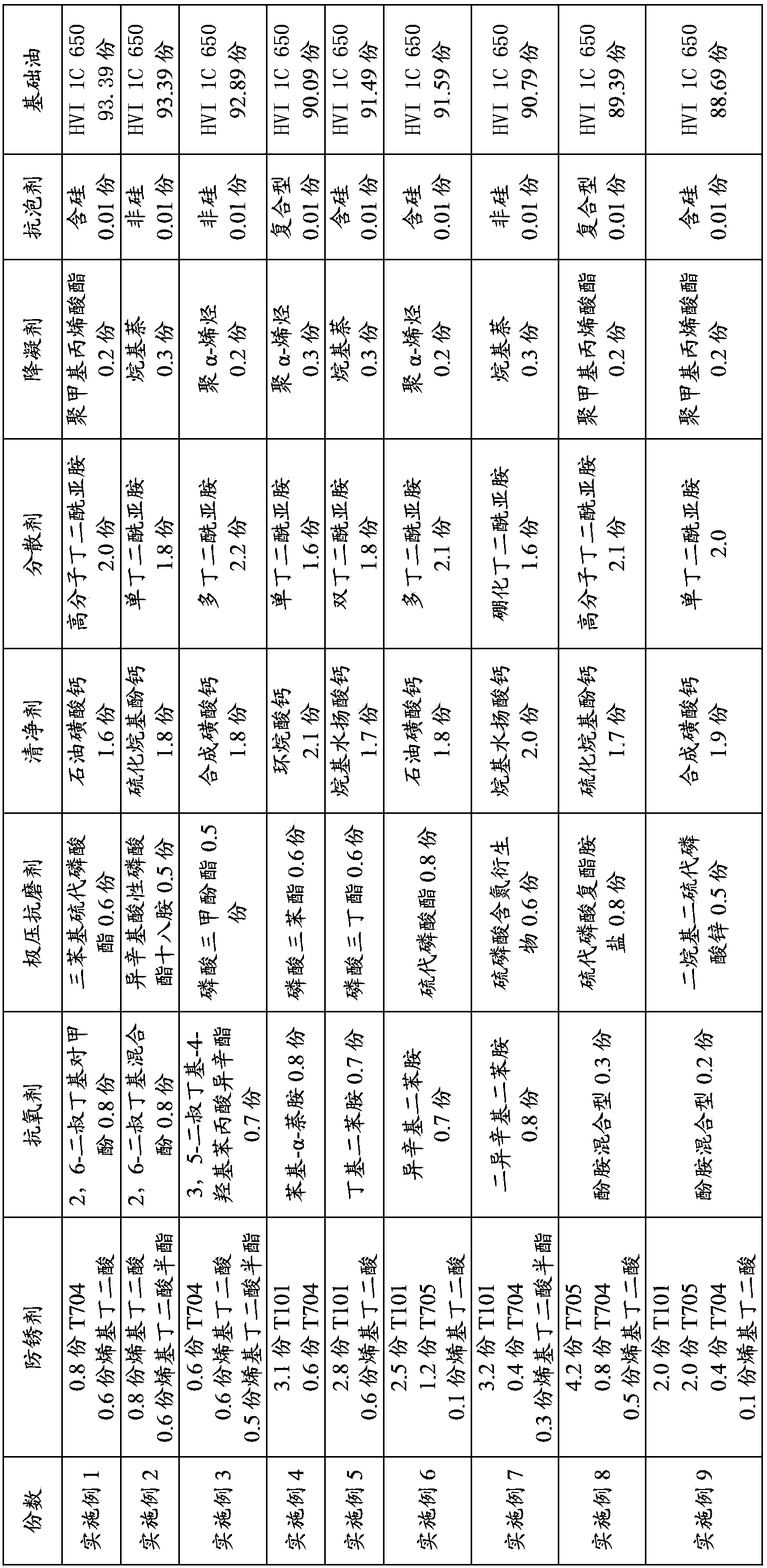

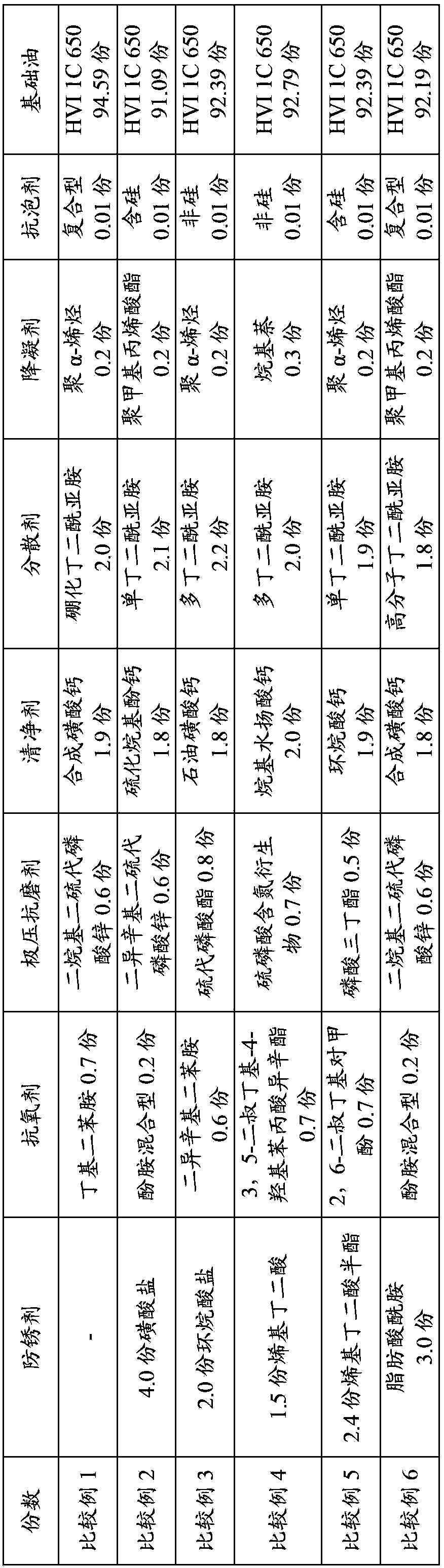

[0034] Add each component into the base oil in proportion at 55° C., stir for 0.5 to 5 hours to dissolve them all, and obtain a lubricating antirust oil composition for marine diesel engines. See Table 1 for details.

[0035] In Table 1, T704 is zinc naphthenate, T101 is calcium petroleum sulfonate with low alkali value, and T705 is barium dinonyl naphthalene sulfonate.

Embodiment 10

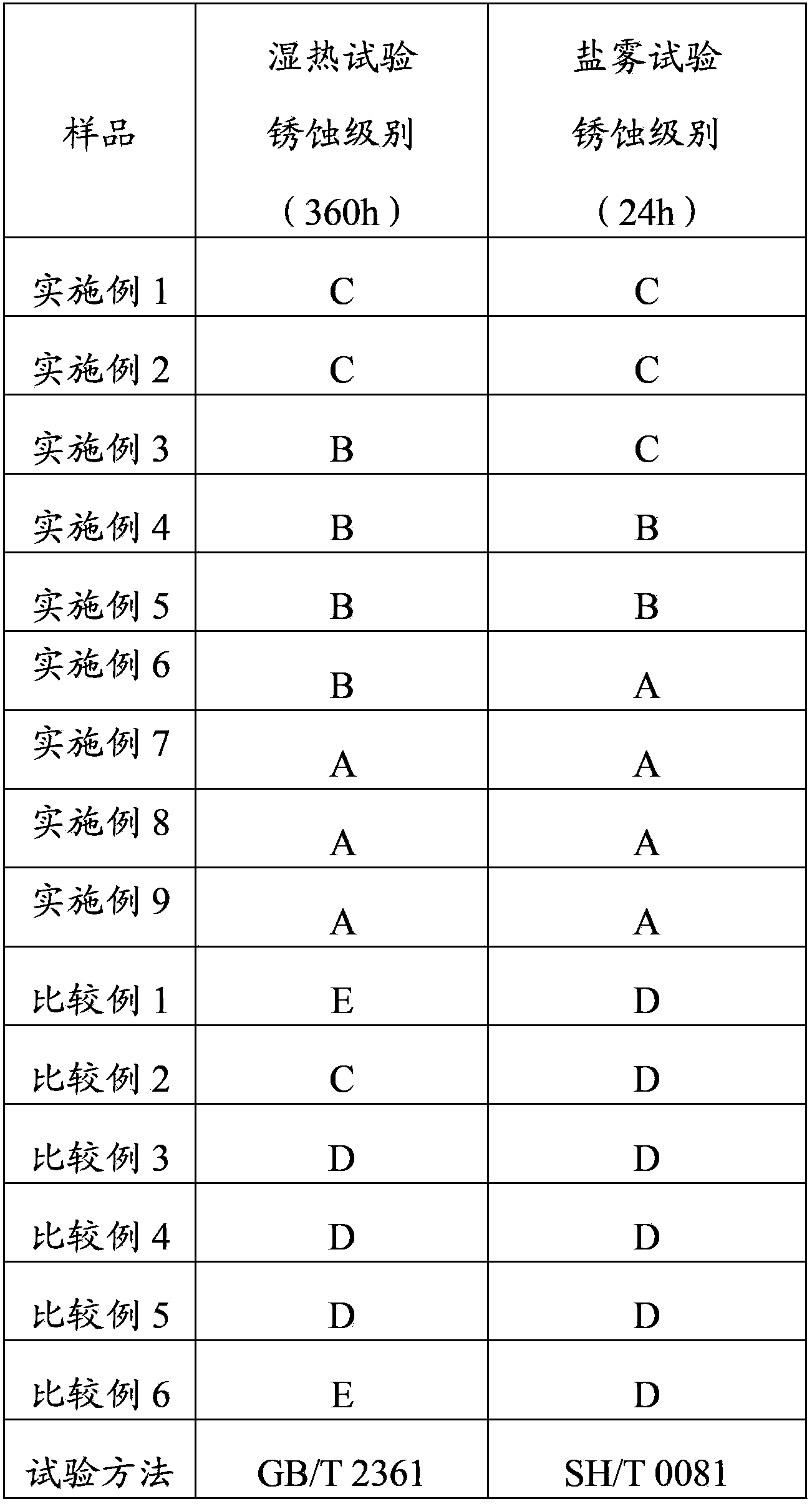

[0043] The thermal oxidation stability of the lubricating and antirust oil compositions for marine diesel engines in [Examples 1-9] was investigated. The results are shown in Table 3 and Table 4.

[0044] table 3

[0045]

[0046] Table 4

[0047]

[0048] As shown in Table 4, after adding suitable antirust additives, the lubricating and antirust oil composition for marine diesel engines not only passed the engine standard bench test, but also achieved medium and short-term antirust performance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com