Low-alloy steel plate and heat treatment method for steel plate

A heat treatment method and low alloy technology, applied in the field of medium and heavy plate steel plate production, can solve the problems of coarse grains, poor flexibility of water cooling process, high cost, reduce carbon and alloying element content, shorten high temperature residence time, improve weldability performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The following are preferred embodiments of the application, which are only used as explanations of the application rather than limitation.

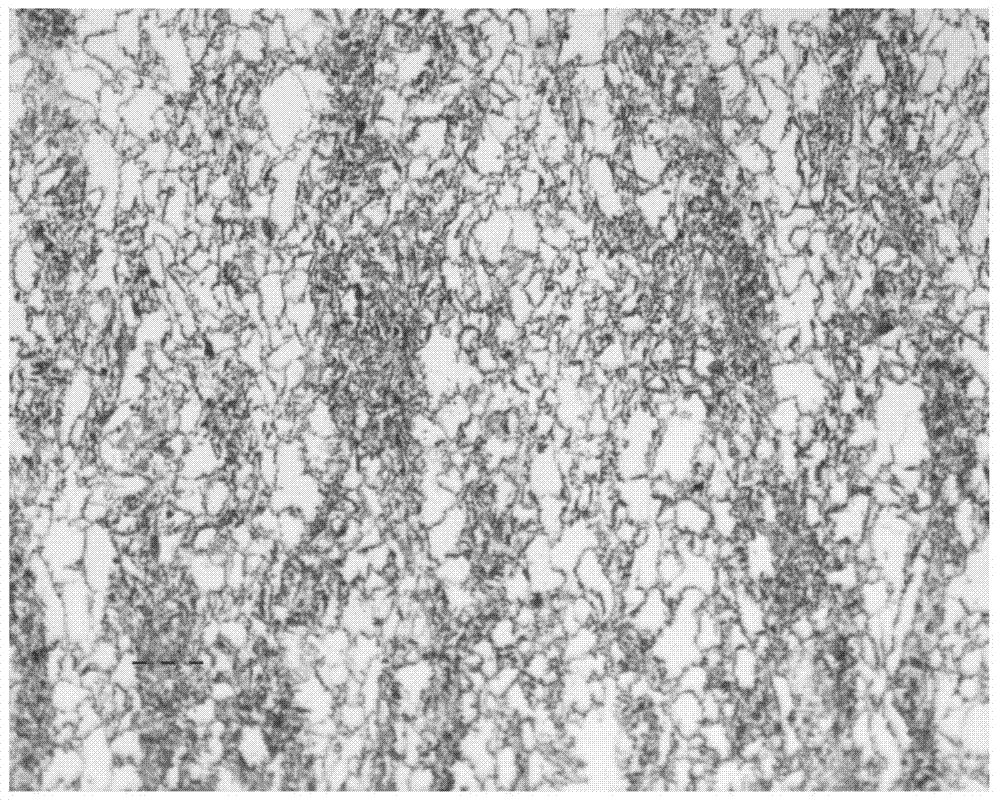

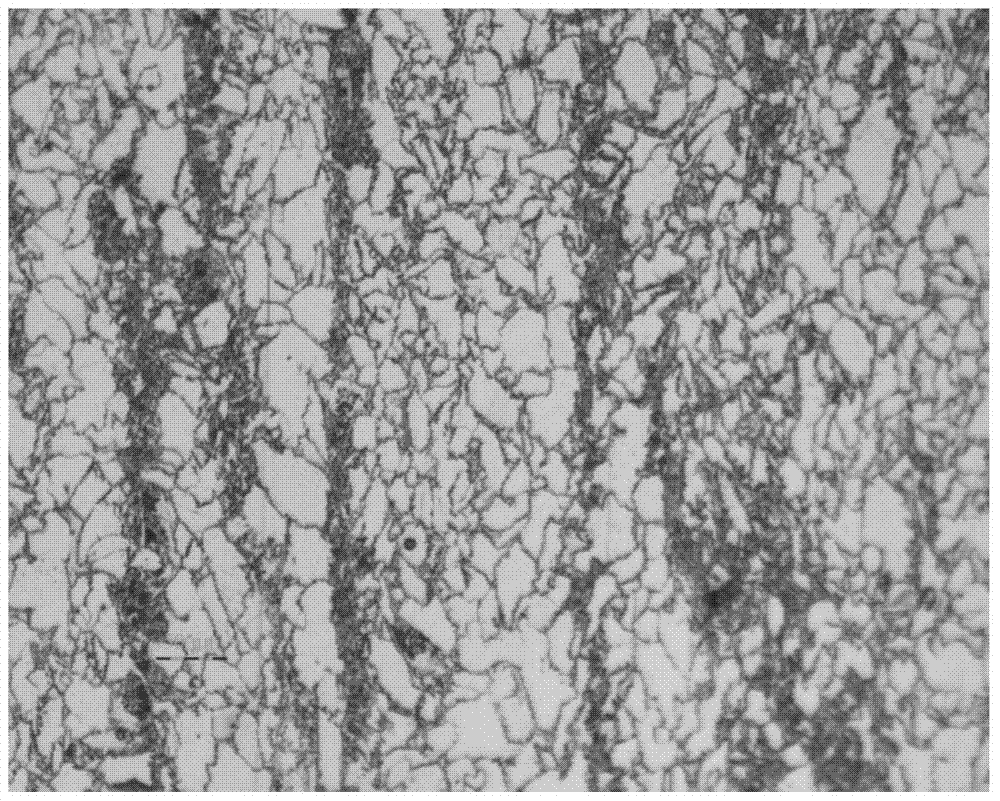

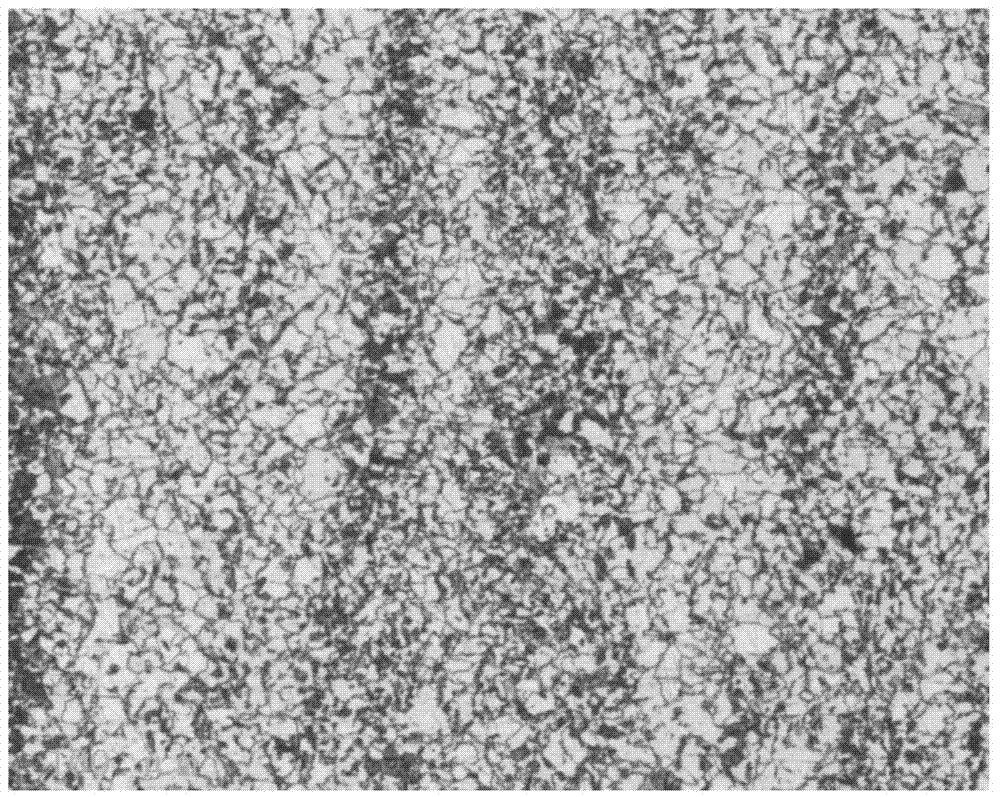

[0036]The chemical composition of the Q460 series of normalized steel plates is shown in Table 1. They were smelted in a converter and cast into continuous casting slabs. The continuous casting slabs were heated in a heating furnace and rolled by a medium plate rolling mill. See Table 2 for the main process parameters such as billet exit temperature, finish rolling start temperature, and final cooling temperature. The main process parameters such as normalizing heating temperature, holding time and final cooling temperature of the steel plate are shown in Table 3. The properties of the corresponding steel plates such as tensile strength, elongation, and 0°C longitudinal impact energy are shown in Table 4. It can be seen that the present invention has excellent low-temperature impact toughness while ensuring the strength of the stee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com