Rear drying system used for multi-cylinder long mesh paper machine

A post-drying, paper machine technology, applied in the paper machine, paper making, textiles and paper making, etc., can solve the problems of large expansion ratio of paper, large amount of sizing of high filler paper, low drying temperature, etc. Possibility, small stretch rate of paper, effect of accelerating dewatering rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

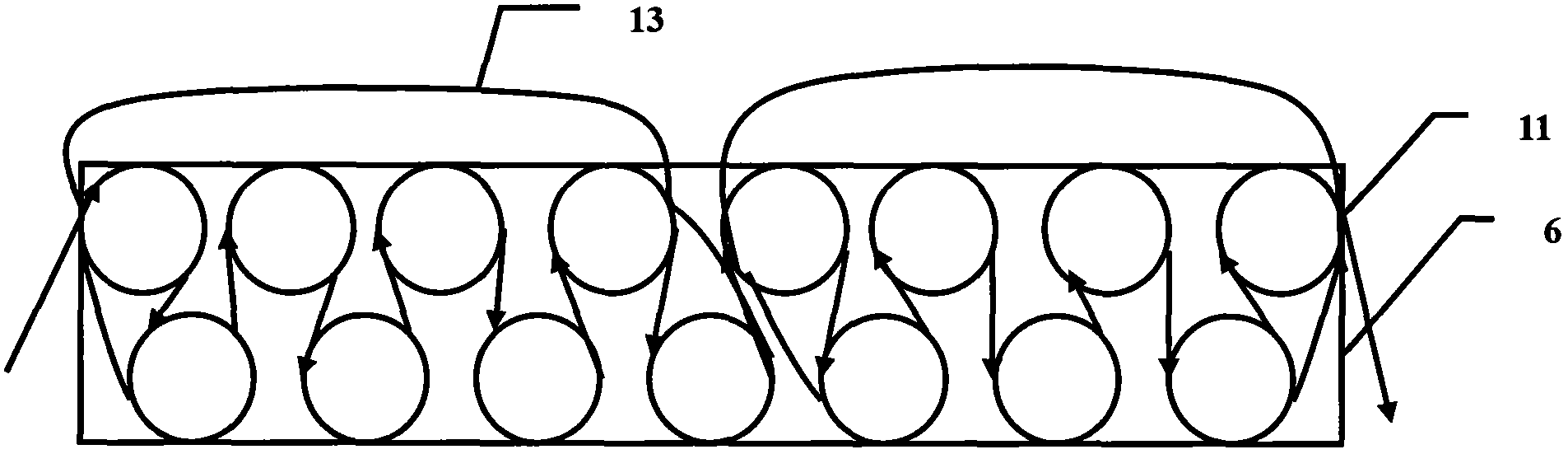

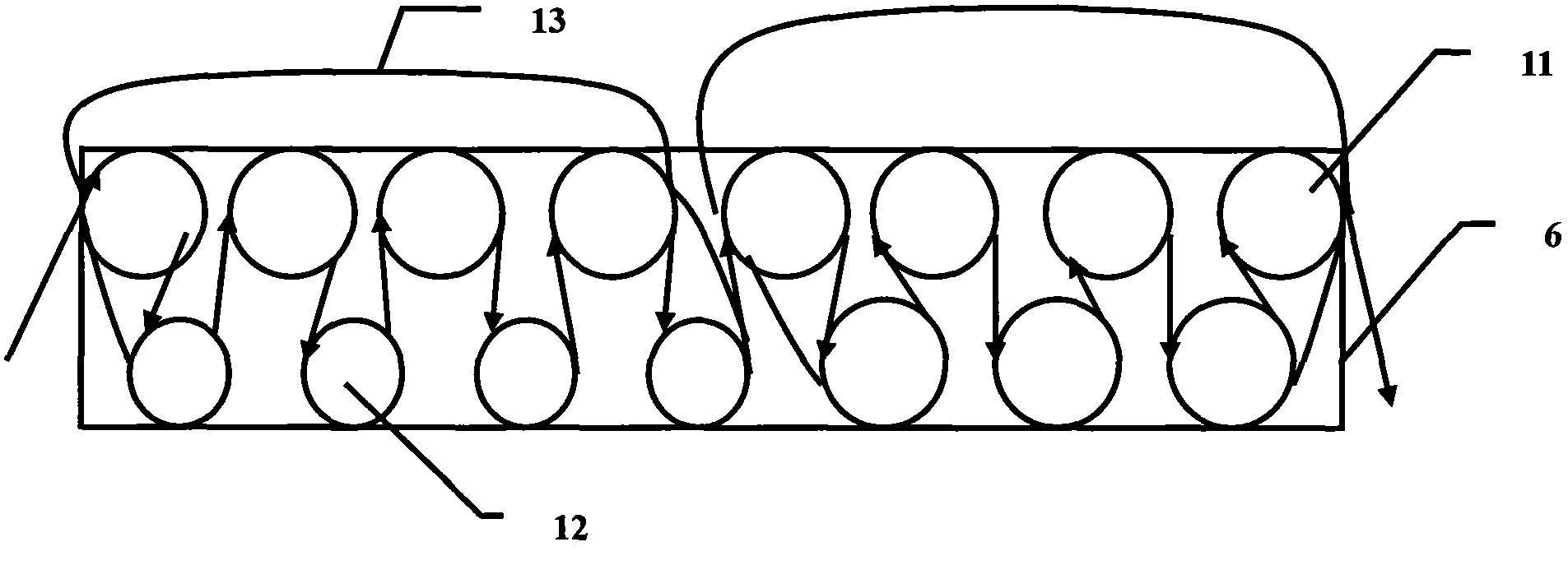

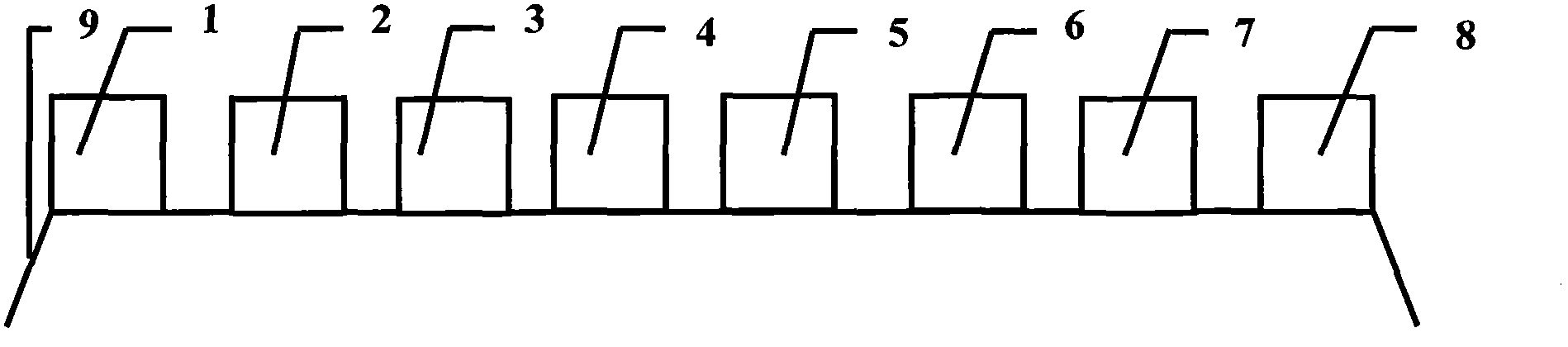

[0028] Such as Figure 4 As shown, a post-drying system for fourdrinier multi-cylinder paper machines according to the present invention has an enhanced drying device 10 and a post-drying part 6; entrance;

[0029] The enhanced drying device 10 can be enhanced drying equipment such as a far-infrared oven and a steam box; the enhanced drying device 10 can forcefully dry the paper after it leaves the sizing machine 5, so as to ensure that the sizing material on the surface of the paper is rapidly preheated and accelerated. Dehydration, so that the paper has a certain temperature when it enters the rear drying part 6, so the quality of sizing can be improved and the dryness of the finished paper can meet the corresponding requirements.

[0030] Compare image 3 , 4 As shown in the post-drying system, the area of the post-drying system of the present invention is relatively larger than that of the traditional paper machine post-drying system with the same width and speed;

...

Embodiment 2

[0037] A post-drying system used on a fourdrinier multi-cylinder paper machine, it only has a post-drying part 6, and the structure of the post-drying part 6 is the same as that of Embodiment 1, without the enhanced drying device 10;

[0038] Compared with the traditional post-drying system, the structure of the post-drying system described in Example 2 also solves the problem that the traditional pre-drying system is not suitable for producing high-filler pulp.

[0039] The content of the present invention is not limited to the content of this embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com