Construction method with space gas film as formwork

A construction method and formwork technology, which is applied in the direction of building types, buildings, large-capacity bulk material storage, etc., can solve the problems of high labor costs, long construction period, and low safety factor, and achieve simple operation, short construction period, and reduced The effect of labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

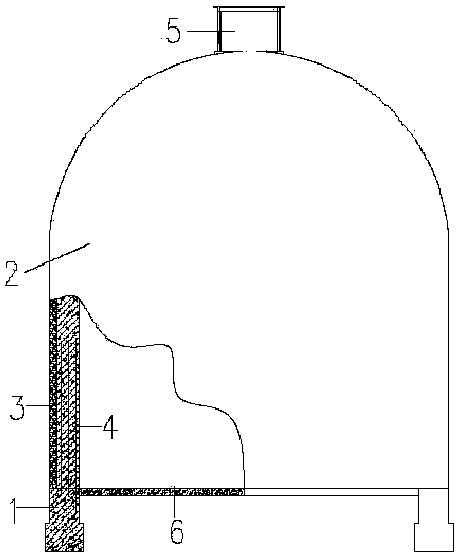

[0010] refer to figure 1 , according to the specifications and models designed by the construction project, the air film formwork 2 is processed and formed in the factory according to the engineering design. Forming and inflating, as the outer membrane of the reinforced concrete structure, the air film formwork 2 is an ellipsoid, cylinder, hemisphere or cylinder. After the processing is completed, the air film formwork 2 is transported to the construction site, and the air film formwork 2 is fixed and Before inflating, cover the inside of the air film formwork 2 of the hydraulic crane, building materials, and construction equipment in place, unfold the air film formwork 2 and fix it on the foundation 1, and after the air film formwork 2 is inflated and formed, the hydraulic crane, building materials, and construction equipment are located in the air On the floor 6 inside the building of the membrane formwork 2; after the air film formwork 2 is installed and inflated, keep the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com