Separation and assay determination method for components of tetrabromobisphenol A

A Tetrabromobisphenol A, determination method technology, applied in the direction of material separation, analysis materials, measuring devices, etc., can solve the problem that there is no fast and accurate determination method for the purity and impurity content of tetrabromobisphenol A

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Instruments and Conditions

[0036] High performance liquid chromatography: Agilent 1100

[0037] Chromatographic column: Octadecyl bonded silica gel as filler (250mm×4.6mm, 5μm)

[0038] Mobile phase: acetonitrile: water = 50: 50 ~ 0: 100 (volume ratio)

[0039] Gradient elution conditions: 0-30min, the ratio of acetonitrile: water is uniformly changed from 50:50 (volume ratio) to 0:100 (volume ratio).

[0040] Detection wavelength: 254nm

[0041] Column temperature: 30°C

[0042] Injection volume: 20μl

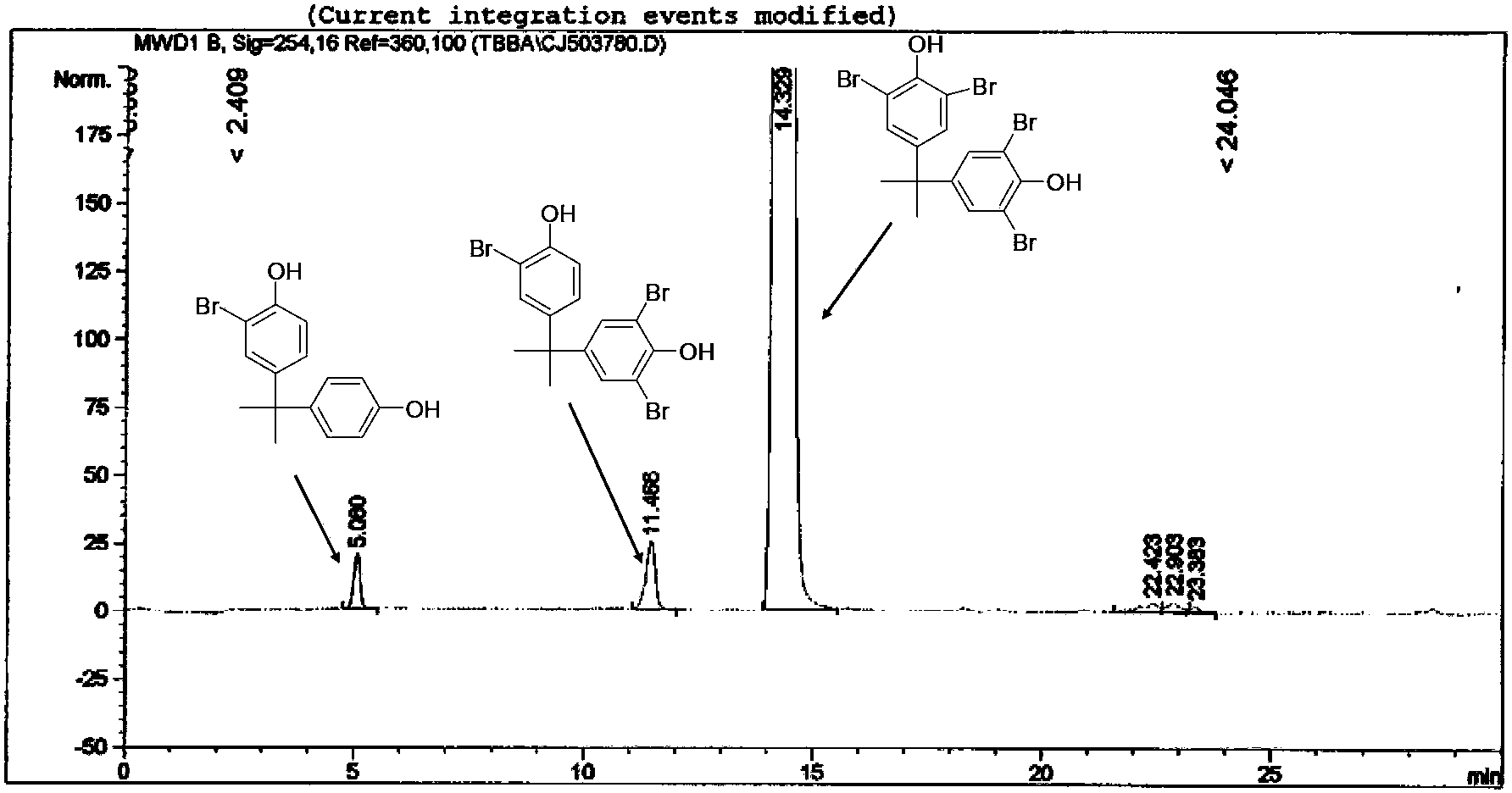

[0043] Experimental procedure: Weigh 0.1g of Tetrabromobisphenol A sample A, place it in a 10ml volumetric flask, add acetonitrile to dissolve, dilute to the mark, shake well, and use it as the test sample solution, and carry out HPLC analysis under the above chromatographic conditions , record the chromatogram, see the results figure 1 .

[0044] Component results:

[0045] Retention time (min)

[0046] 22.423~23.383

Embodiment 2

[0048] Instruments and Conditions

[0049] High performance liquid chromatography: Agilent 1100

[0050] Chromatographic column: Octadecyl bonded silica gel as filler (250mm×4.6mm, 5μm)

[0051] Mobile phase: acetonitrile: water = 50: 50 ~ 0: 100 (volume ratio)

[0052] Gradient elution conditions: 0-30min, the ratio of acetonitrile: water is uniformly changed from 50:50 (volume ratio) to 0:100 (volume ratio).

[0053] Detection wavelength: 254nm

[0054] Column temperature: 30°C

[0055] Injection volume: 20μl

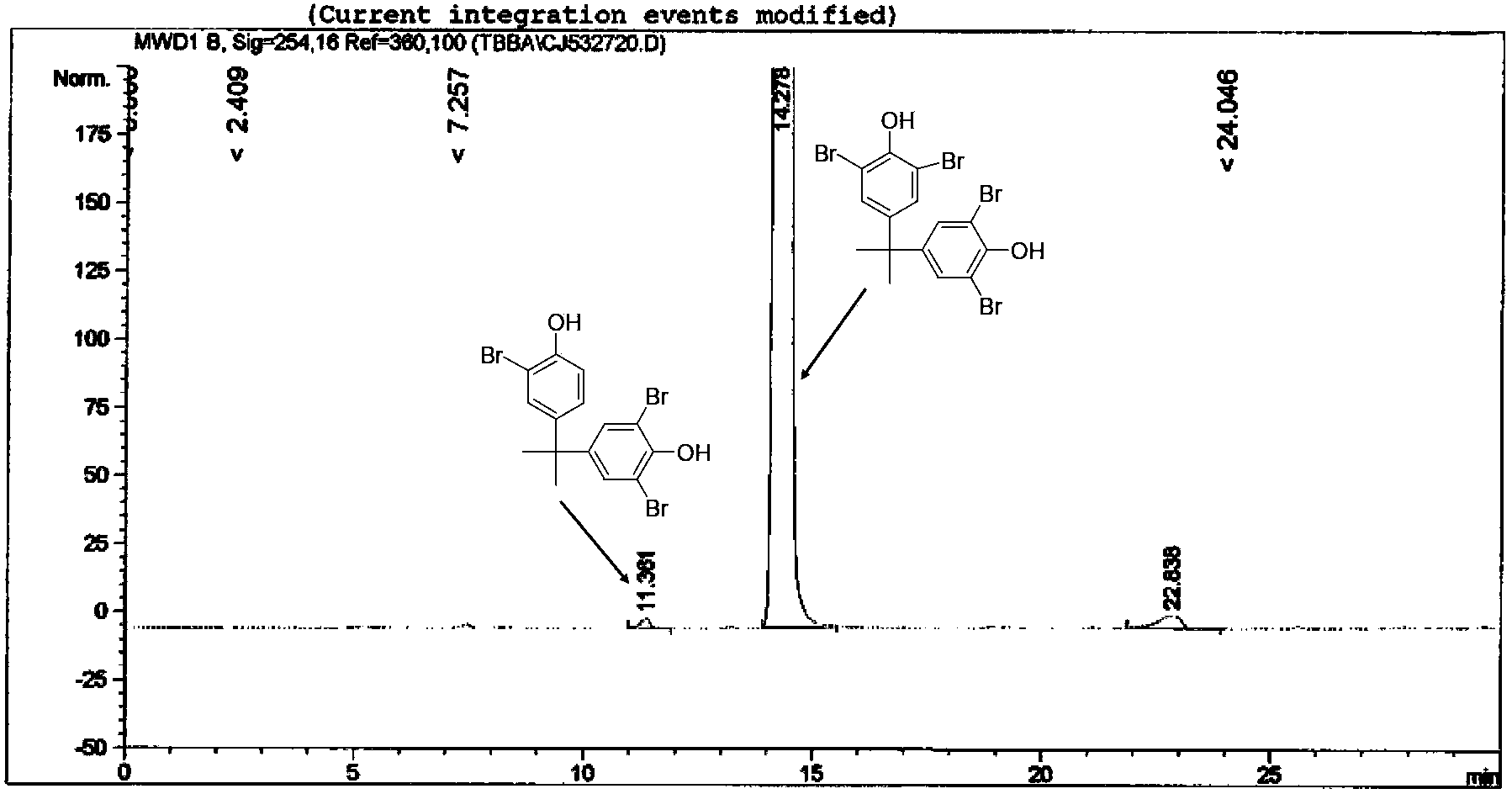

[0056] Experimental procedure: Weigh 0.1g of tetrabromobisphenol A sample B, put it in a 10ml volumetric flask, add acetonitrile to dissolve, dilute to the mark, shake well, and use it as a test sample solution, and perform HPLC analysis under the above chromatographic conditions , record the chromatogram, the results are shown in the attached figure 2 .

[0057] Component results:

[0058] Retention time (min)

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com