A beat-type fully automatic delivery test system

A factory-tested, fully automatic technology, applied in the field of motor manufacturing, can solve problems such as difficulty in adapting to the production line production rhythm, strong dependence on testers, low test efficiency, etc., to improve accuracy and repeatability, avoid test requirements, improve Effects of reliability and security

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the present invention more comprehensible, preferred embodiments are described in detail below with accompanying drawings.

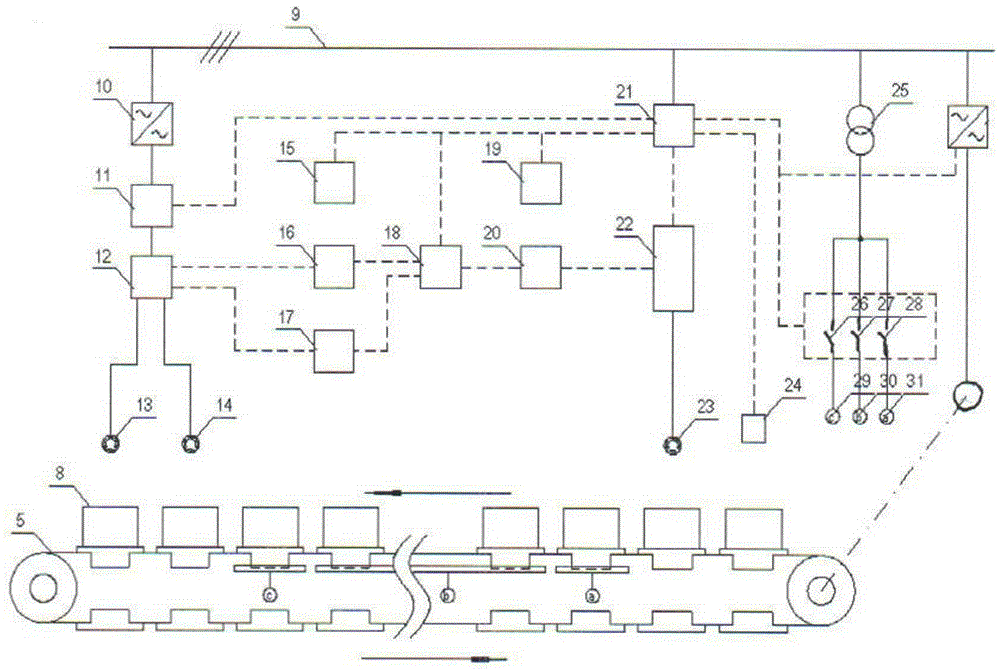

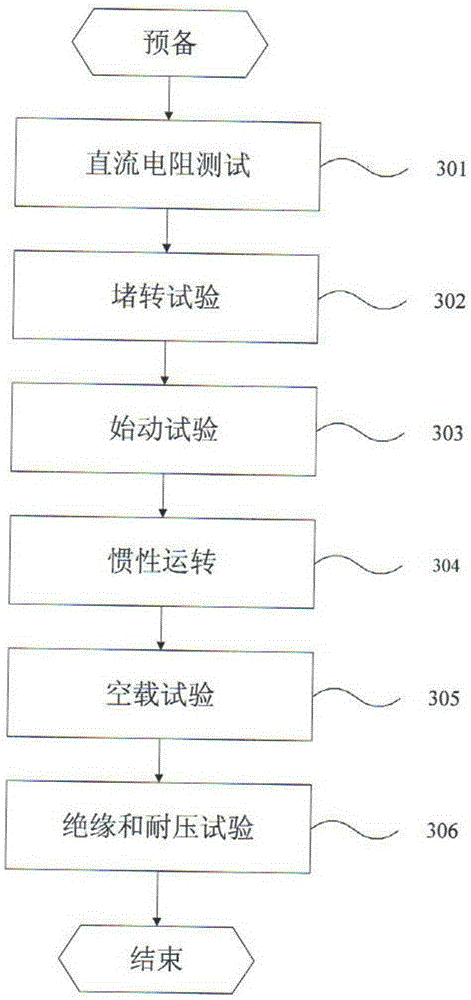

[0023] Such as figure 1 As shown, a kind of beat-type fully automatic factory test system provided by the present invention includes a roller table system 5 that continuously drives the tested motor 8 on it to different stations with a preset working beat. The stations include the preparation station, the DC resistance test station, the stall test station, the start station, the number of inertial operation stations configured according to the needs, the inertial operation stop station, the no-load test station and the insulation and withstand voltage test station. bit. The roller table system 5 of this system runs at a certain speed under the drive of the driving motor 32, and this speed can be adjusted according to the production rhythm, whether it is fast or slow.

[0024] The motor 8 to be tested is safely placed on the roll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com