Vertical microelectronic component and corresponding manufacturing method

A technology of microelectronic components and areas, applied in the direction of electrical components, semiconductor/solid-state device manufacturing, electric solid-state devices, etc., to achieve the effects of small resistance, high power density, and small area consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In the figures, identical reference numbers designate identical or functionally identical elements.

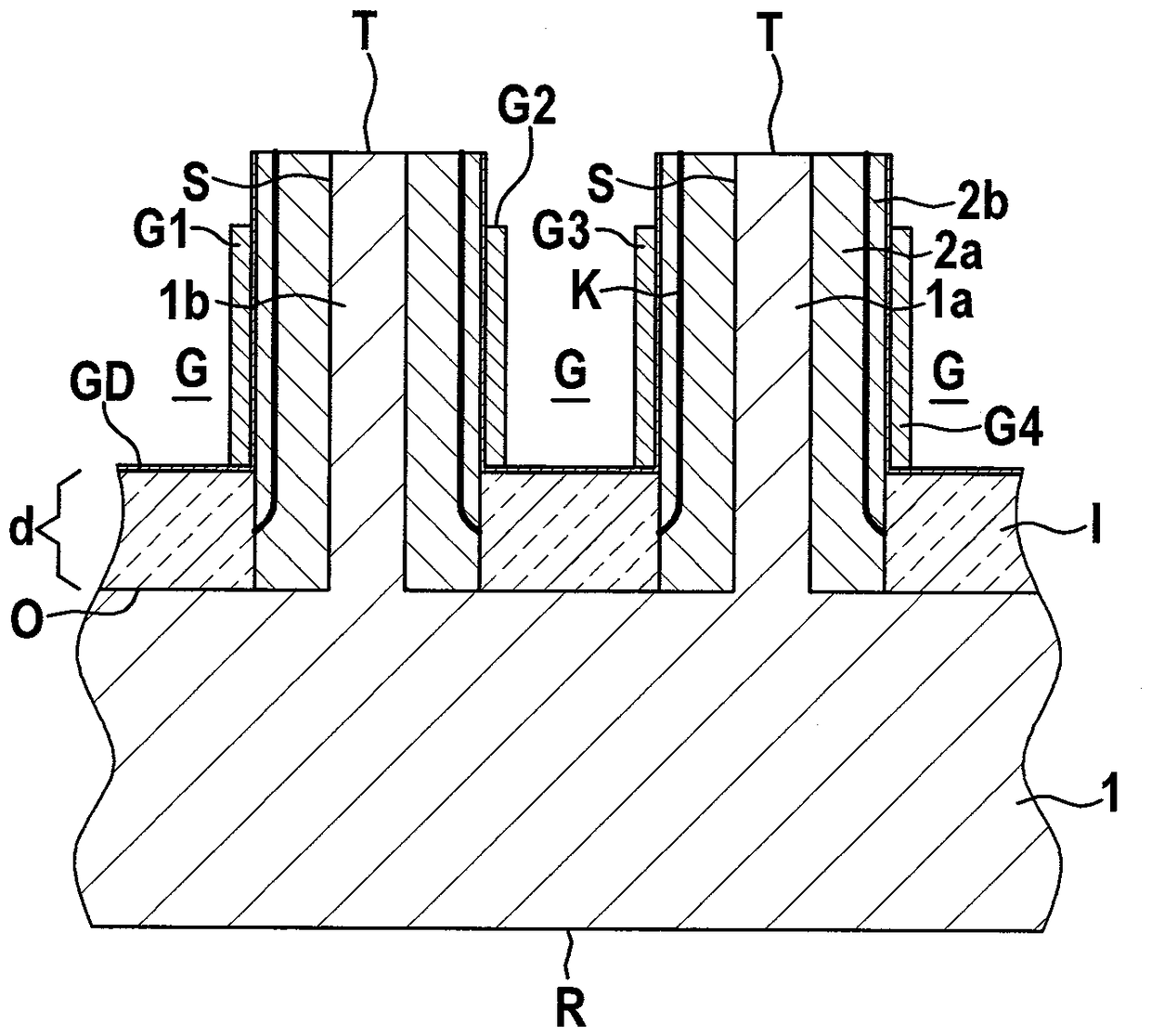

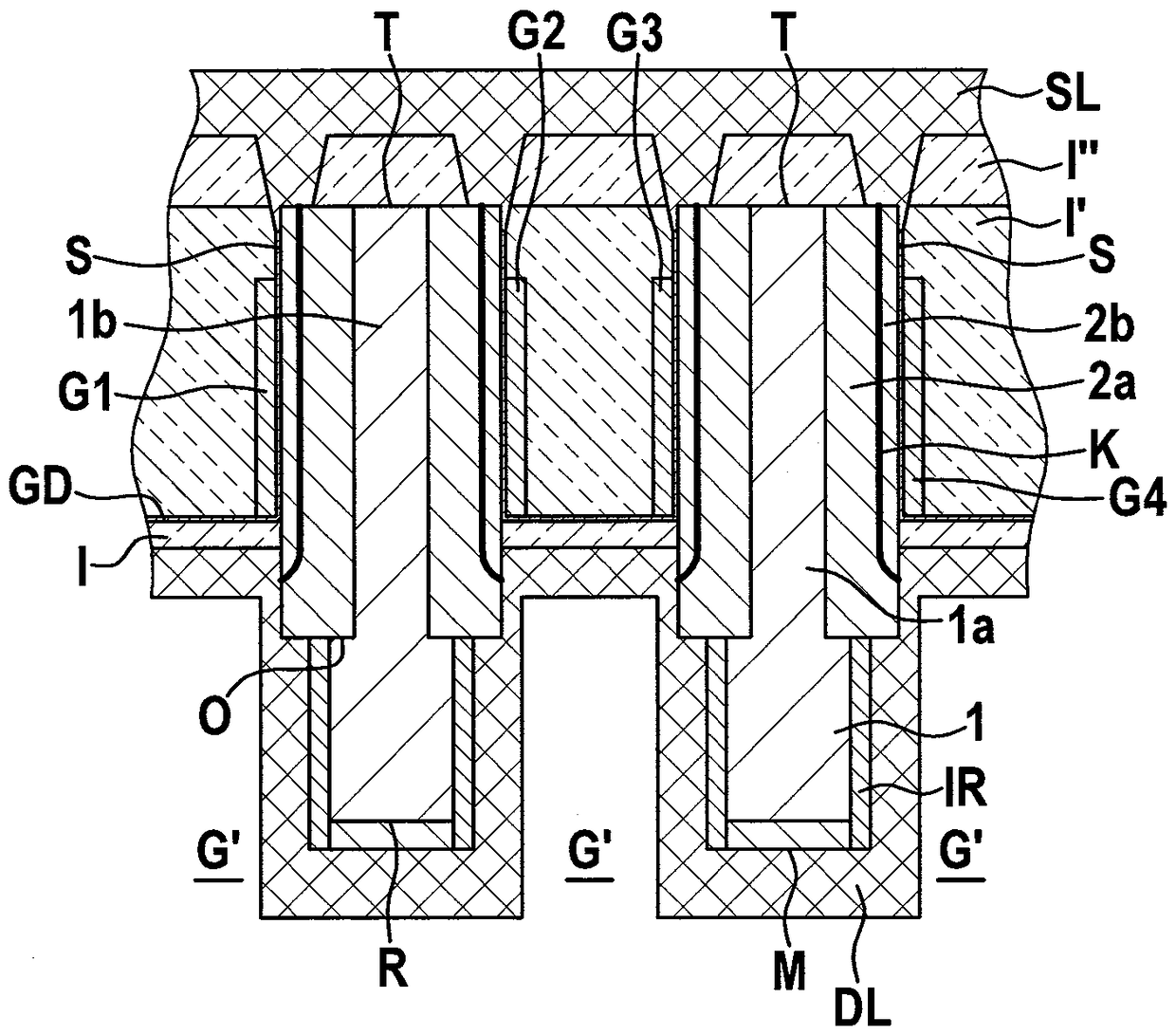

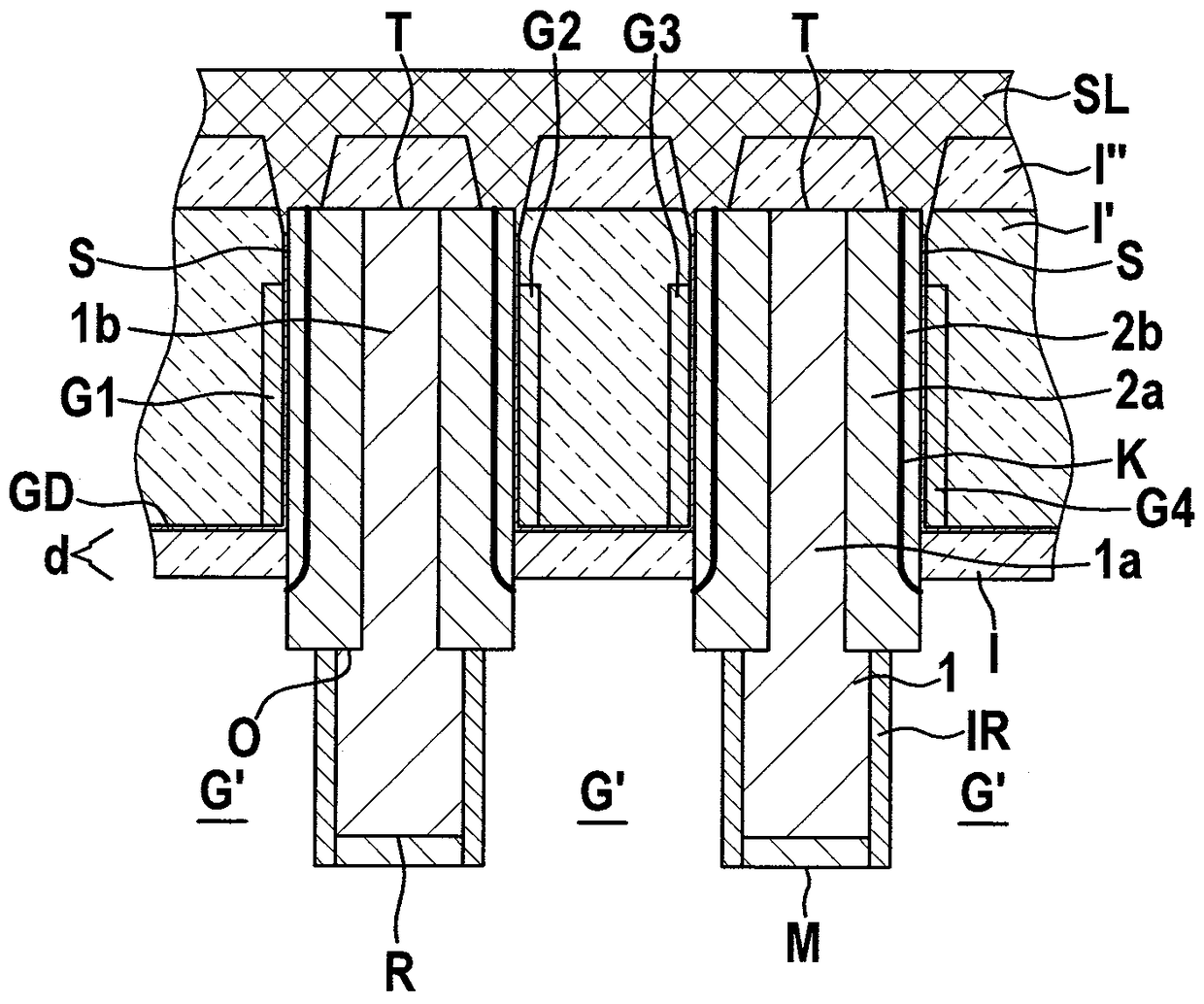

[0021] Figure 1a )-o) are schematic cross-sectional views for explaining a vertical microelectronic component according to an embodiment of the invention and the corresponding manufacturing method.

[0022] exist Figure 1a ), reference numeral 1 denotes a silicon-semiconductor base having a front side O and a backside R. On the front side O of the silicon-semiconductor base 1 a large number of fins 1a, 1b are formed by means of a trench etching process, between which there are recesses G in the silicon-semiconductor base. In this example, the etched recess G is selected such that it lies perpendicular to the (111) crystal plane in the silicon-semiconductor substrate 1 . The side walls of the fins 1a, 1b are denoted by reference S, and the upper faces thereof by T. The structure of the fins 1a, 1b can be one-dimensional (for example linear), but also two-dimensional ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com