Gasoline engine assisted palm leaf cutting device

A cutting device and palm leaf technology, applied in cutting tools, cutting equipment, agricultural machinery and machinery, etc., can solve the problems of not being able to adapt to the rapid development of productivity, low operating efficiency, high labor intensity, etc., to achieve efficient mechanized operations and reduce labor costs , the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

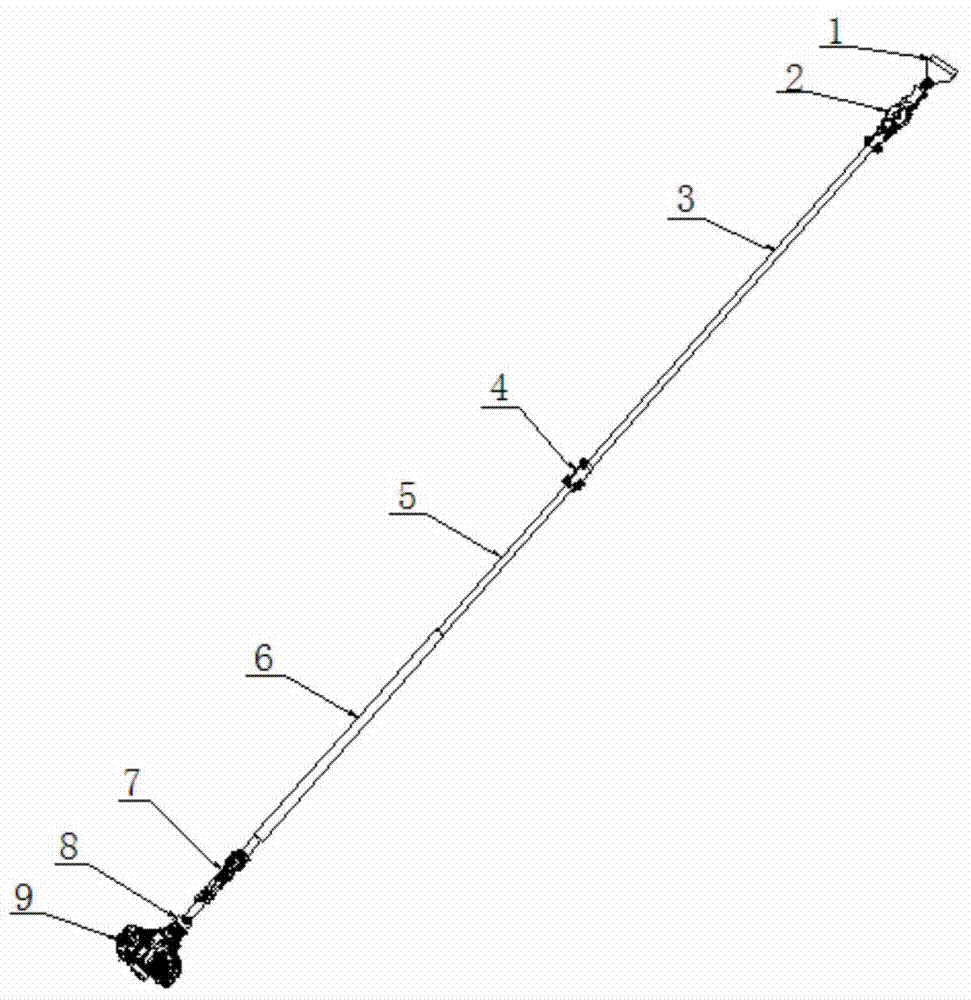

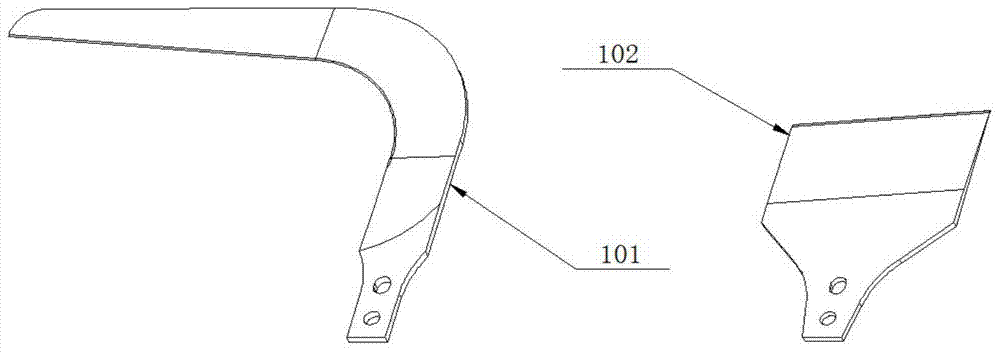

[0034] The present invention includes a blade 1 , a gear box 2 , an extension pipe assembly 3 , a pipe connector 4 , a pipe assembly 5 , a rubber sleeve 6 , a throttle cable assembly 7 , a cover assembly 8 , and an engine 9 .

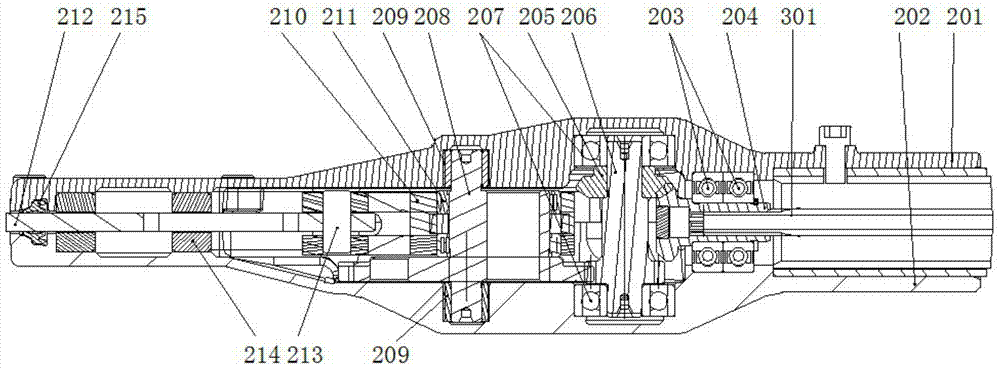

[0035] The output shaft of the engine 9 and the cover 8 are connected by the hub assembly 801, the hub assembly 801 and the hollow drive shaft II501 of the tube assembly 5 are connected by an involute spline, and the hollow drive shaft II501 and the extension tube assembly 3 The hollow drive shaft I301 is connected by Involute spline connection, the hollow drive shaft I301 and pinion 204 are connected by involute spline.

[0036] The throttle cable assembly 7 is provided with a start-stop switch 701 and a throttle control switch 702 of the engine 9, set the start-stop switch 701 of the throttle cable to the ON state, and then pull the engine 9, the engine 9 starts to run, wait a moment, After the engine is fully warmed up, by adjusting the throttle cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com