Slow-release pesticide and preparation method thereof

A slow-release, pesticide technology, applied in the field of pesticides, can solve the problems of difficulty in realizing slow-release pesticides and poor rain resistance, and achieve the effects of good rain resistance, low raw material cost, and good water resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0047] The invention provides a kind of preparation method of sustained-release pesticide, comprising the following steps:

[0048] a, mixing the starch-based surfactant with water to obtain the first mixed solution;

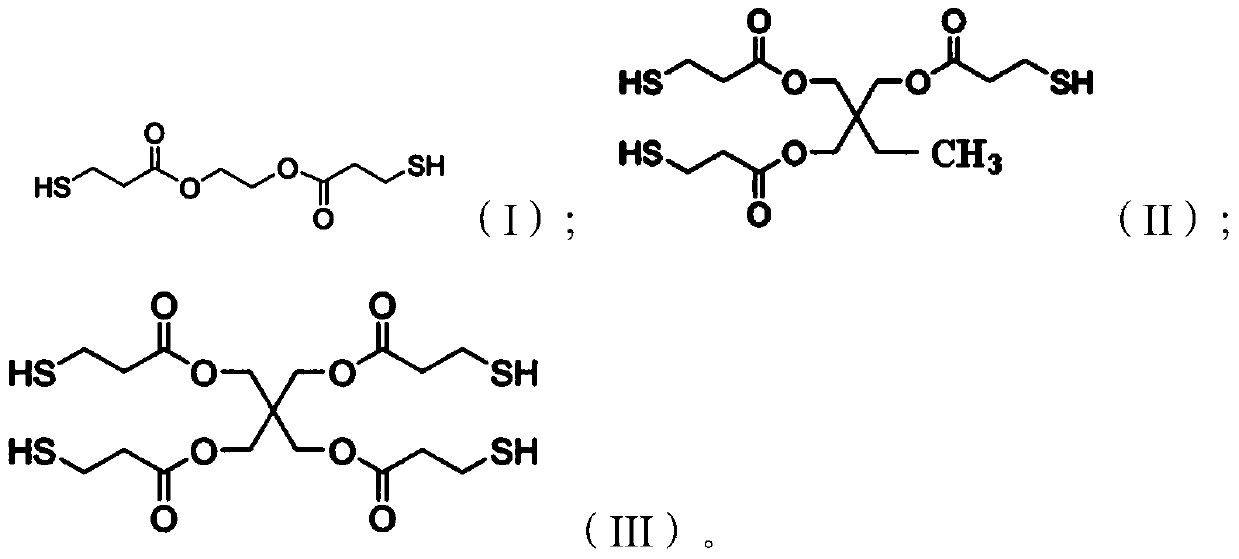

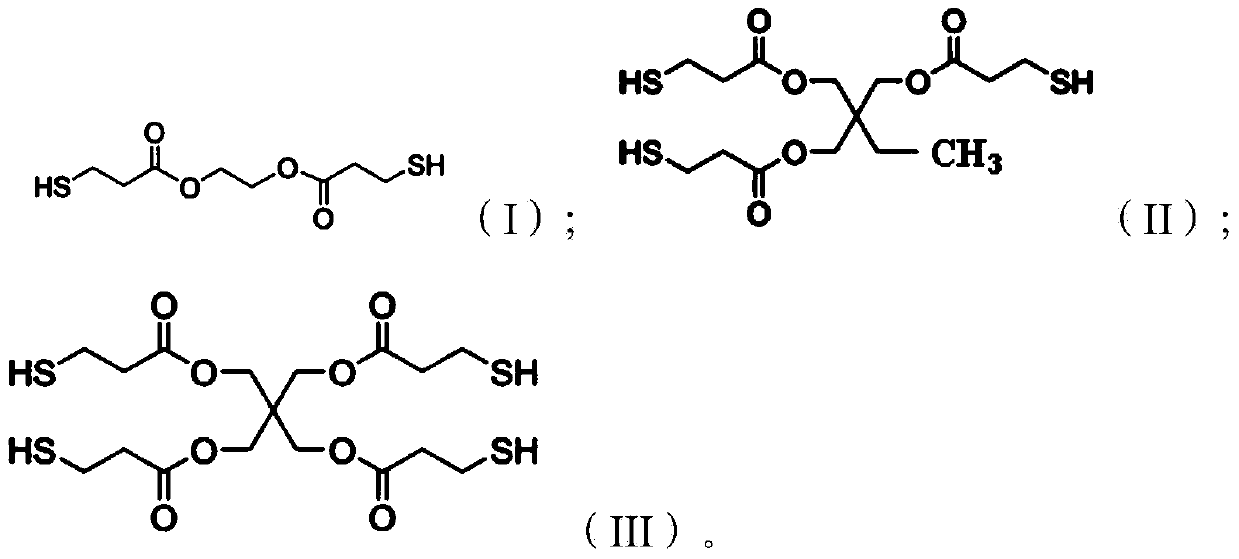

[0049] b. Mixing the hydrophobic pesticide agent, the mercapto compound and the oil phase to obtain a second mixed solution;

[0050] c. emulsifying after mixing the first mixed solution and the second mixed solution to obtain an oil-in-water emulsion;

[0051] d. performing a click reaction on the oil-in-water emulsion under photoinitiation to obtain a reaction product;

[0052] e, removing the oil phase and the water phase in the reaction product to obtain slow-release pesticides;

[0053] The steps a and b are not limited in time sequence.

[0054] In the present invention, the starch-based surfactant is mixed with the water phase to obtain a first mixed solution; preferably, the starch-based surfactant is dissolved in the water phase to obtain the first m...

Embodiment 1

[0071] Dissolve 100g of starch octenyl succinate with a degree of substitution of 0.05 in 1000g of water to obtain the first mixed solution;

[0072] 25g of 2,4-D pesticide and 3.37g of pentaerythritol tetramercaptoacetate were dissolved in 1000mL of dichloromethane to obtain a second mixed solution;

[0073] emulsifying the first mixed solution and the second mixed solution in an emulsifier for 3 minutes to obtain an oil-in-water emulsion, the rotational speed of the emulsifier is 12000 rpm, and the emulsification temperature is 10°C;

[0074]The above oil-in-water emulsion was irradiated under ultraviolet light for 10 minutes to perform a click reaction to obtain a reaction product, and the reaction temperature of the click reaction was 25°C;

[0075] The above reaction product is subjected to rotary steaming treatment at 30°C to remove the dichloromethane; the reaction product after the removal of dichloromethane is subjected to freeze-drying treatment to remove the water t...

Embodiment 2

[0079] 50g of starch dodecenyl succinate with a degree of substitution of 0.04 was dissolved in 1000g of water to obtain the first mixed solution;

[0080] The deltamethrin pesticide of 2.5g, the pentaerythritol dimercaptoglycol ester of 1.6g are dissolved in the benzene of 500mL, obtain the second mixed solution;

[0081] emulsifying the first mixed solution and the second mixed solution in an emulsifier for 2 minutes to obtain an oil-in-water emulsion, the rotation speed of the emulsifier is 13000 rpm, and the emulsification temperature is 25°C;

[0082] The above oil-in-water emulsion was irradiated under an ultraviolet lamp for 5 minutes to perform a click reaction to obtain a reaction product, and the reaction temperature of the click reaction was 50°C;

[0083] The above reaction product is subjected to rotary steaming treatment at 50° C. to remove benzene; the reaction product after removing benzene is subjected to freeze-drying treatment to remove water therein to obta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com