Resin precoated sand prepared from reclaimed sand

A technology of resin coating and reclaimed sand, which is applied in the direction of manufacturing tools, casting molding equipment, metal processing equipment, etc., and can solve the problems of different uniformity of resin coating, reduction and increase of resin coated sand, and different mineral components. , to achieve the effects of low casting gas waste defects, low resin consumption, and fast cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

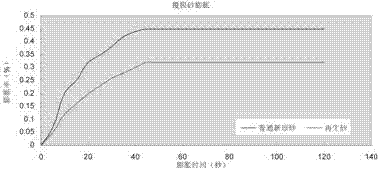

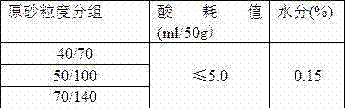

[0020] Resin-coated sand requires raw sand, and its technical quality indicators include particle size grouping number and its distribution, moisture, mud content, and acid consumption value (the total amount of alkaline oxides in raw sand accounts for another proportion of raw sand). A chemical detection expression index).

[0021] The raw sand is as follows:

[0022]

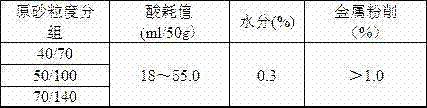

[0023] Foundry waste sand is as follows:

[0024]

[0025] Judging from the relevant status of the foundry waste sand, it is obvious that the sand cannot be used for resin coated sand, and the waste sand needs to be recycled to reach the relevant technical quality indicators of the original sand.

[0026] The present invention adopts a regeneration process method combining thermal regeneration with mechanical and chemical regeneration sand, which includes crushing waste sand, high-flux magnetic separation, screening, mechanical scrubbing, roasting furnace roasting, cooling, screening, high-pass The process of measuri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com