Following adobe cutting and distributing machine

A technology for cutting blanks and blank bricks, which is applied in the field of traveling blank cutting and blanking machines, and can solve the problems of unbalanced frictional resistance, failure to achieve the accuracy of blank bricks, loss of mud strips, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

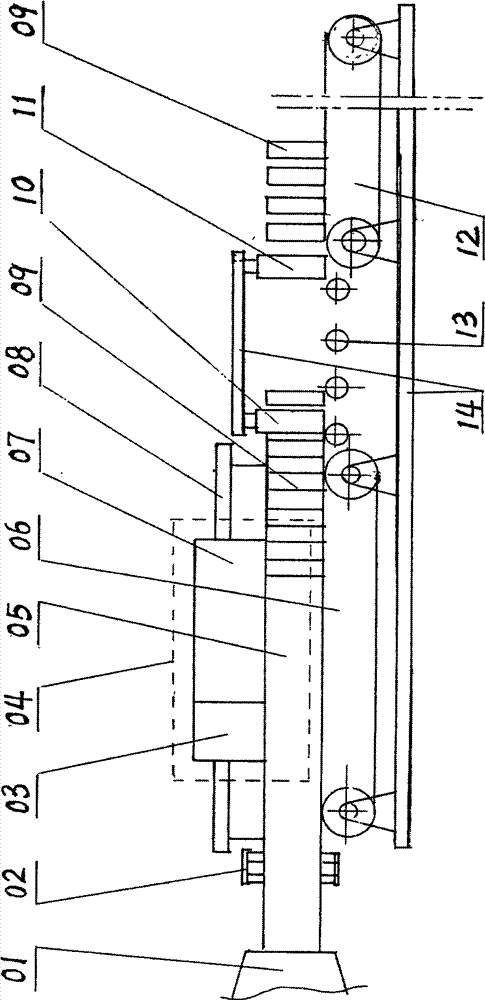

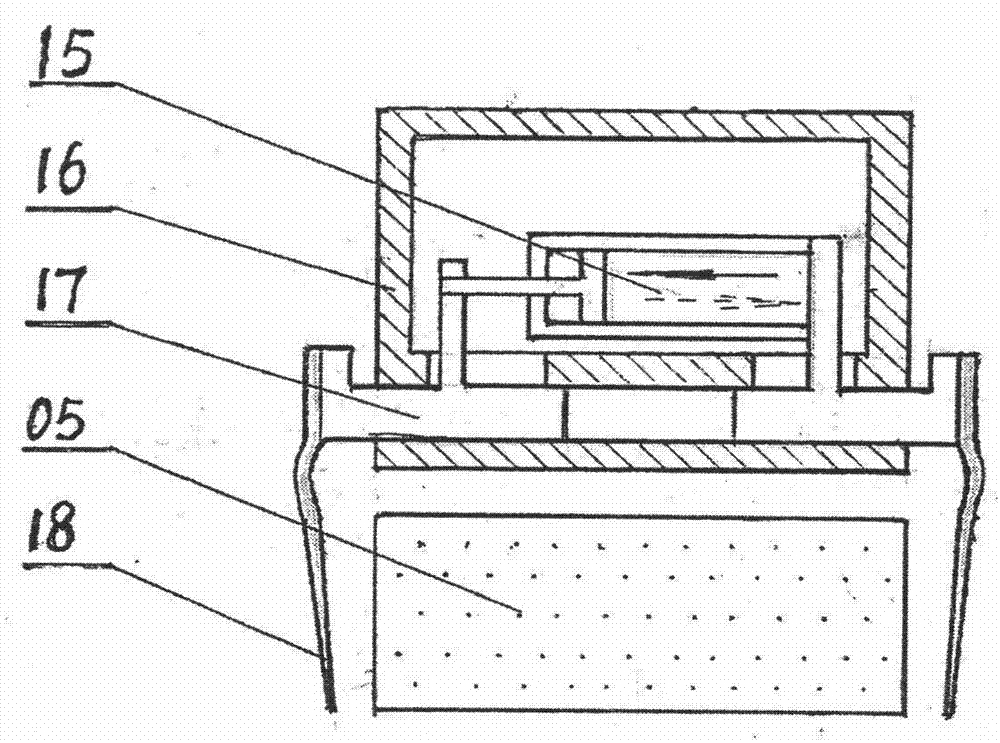

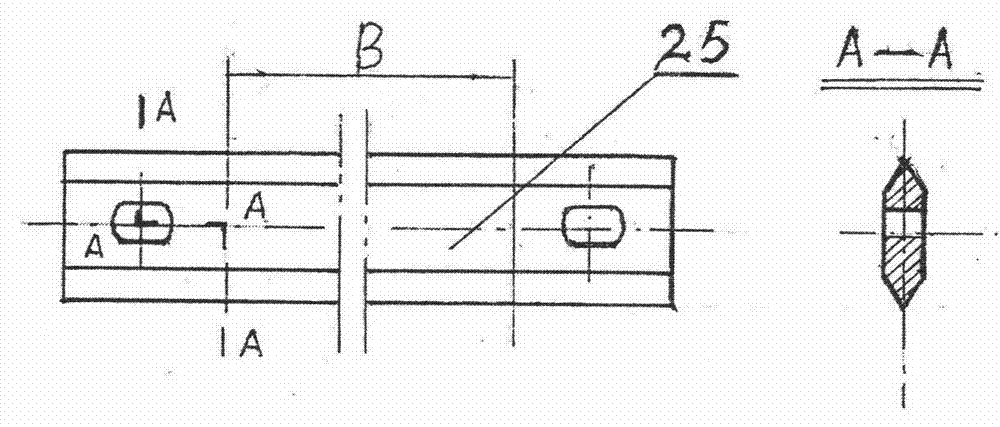

[0029] For the specific working method and procedure of the small shredder, please refer to figure 1 , figure 2 , image 3 .

[0030] When the extruder works, the mud rod (05) is extruded from the extruder outlet (01) and enters the A conveyor belt (06) for a certain distance through the mud rod guide device (02), the laser or infrared measurement of the servo motion mechanism (19) The instrument transmits to the comprehensive control system by measuring the movement of the brick joints (09) and (or) the grooves and (or) marks on the A conveyor belt (06), when the mud strip (05) travels close to the suitable cutting When the length is reached, the servo motion mechanism (19) makes the clamping and dividing device assembly (04) enter quickly along the long guide rail (08) through the moving frame (23), and changes the direction of travel and speed after reaching a suitable cutting position. After the clamping and dividing device assembly (04) entered into a suitable cutting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com