A kind of inorganic finishing mortar with steel slag as main raw material and preparation method thereof

A facing mortar and main raw material technology, applied in the field of building materials, can solve the problems of groundwater quality and plant growth hazards, surrounding environmental pollution, occupying land resources, etc., to improve volume stability and crack resistance, reduce environmental load, The effect of increasing the strength of the post-processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

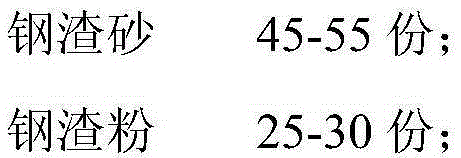

Method used

Image

Examples

Embodiment

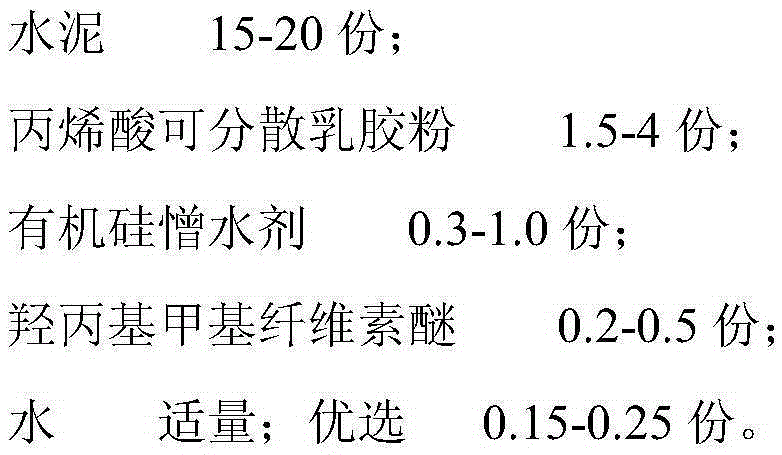

[0035] The formula (parts by weight of materials) of each embodiment material is as shown in Table 1:

[0036] Table 1

[0037]

[0038] In described each embodiment, the preparation method of inorganic facing mortar is:

[0039] (1) Mix the raw materials according to the ratio and stir them;

[0040] (2) Put the material obtained in step 1 into a moisture-proof bag and seal it for storage.

[0041] The process flow chart is as follows:

[0042]

[0043] In step 1, the specific conditions for stirring are: pour water into the container, then slowly pour the powder into the water (stir while pouring the powder into the water), and fully stir with an electric mixer to form a lump-free, uniform paste shape. After the stirring is completed, let it stand for 2-3 minutes and then stir for 1-2 minutes.

[0044] When spraying, the amount of water added is 15-25% of the weight of the mortar powder, and the appropriate adjustment is selected according to the temperature and e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com