Method for improving interface adhesive property of HTPB (hydroxyterminated polybutadiene) liner and NEPE (Nitrate Ester Plasticized Polyether) high-energy propellant

An interface bonding and propellant technology, applied in non-polymer adhesive additives, adhesive additives, etc., can solve the problems affecting the liner/propellant interface bonding performance, low reactive adhesive content, and mechanical properties. Lower than the design value, etc., to reduce adverse effects, improve adhesion performance, and compensate for migration losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

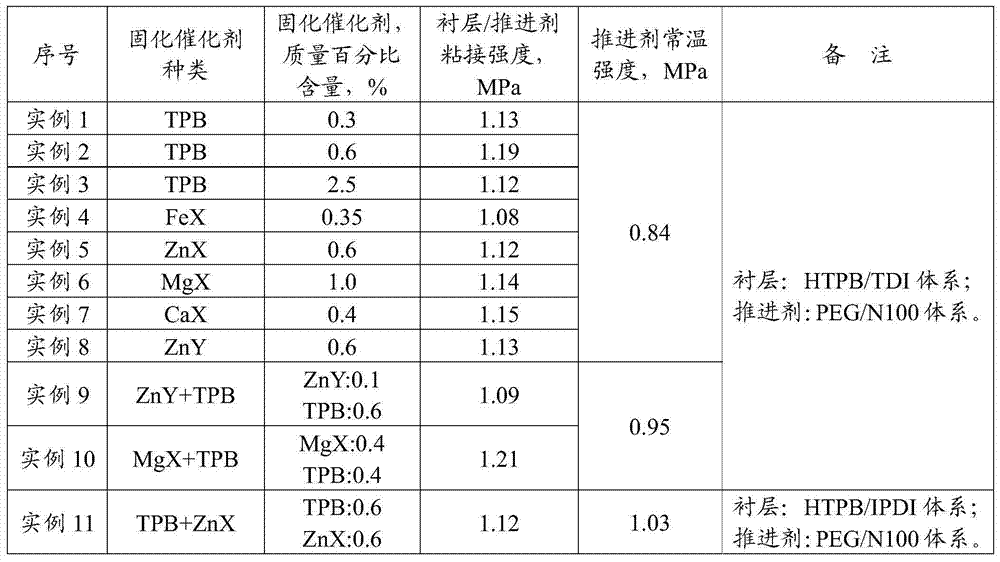

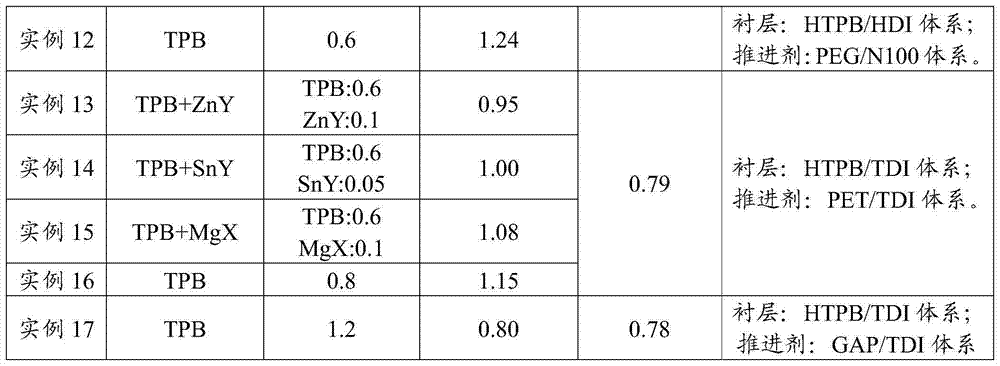

Examples

Embodiment Construction

[0015] Below in conjunction with specific embodiment the present invention is described in further detail, but protection scope of the present invention is not limited thereto, should include the whole scope of claim, any those skilled in the art are familiar with within the technical scope disclosed by the present invention, Easily conceivable changes or substitutions shall fall within the protection scope of the present invention.

[0016] The principle of the present invention is as follows: add a suitable curing catalyst in the HTPB liner to compensate for the migration loss of the curing catalyst in the interface propellant, maintain the curing speed of the interface propellant, and reduce the disadvantages of external factors on the curing and mechanical properties of the interface propellant Influence, improve the bonding performance of the liner / propellant interface.

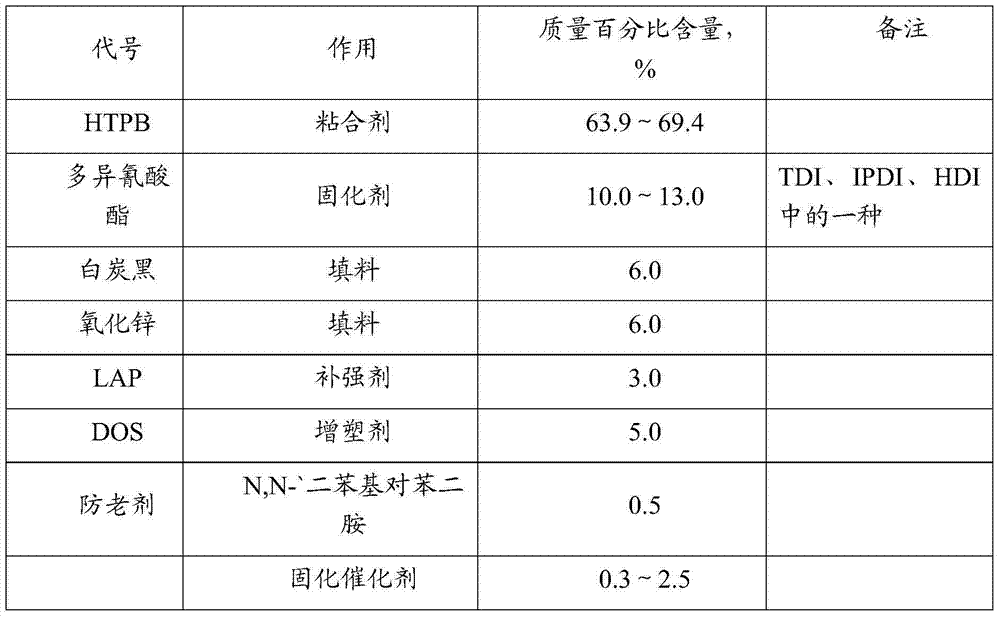

[0017] The formula and composition of the HTPB liner involved in Embodiment 1 to Embodiment 17 of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com