Oil-based lubricant and application thereof

An oil-based lubricant, an alkyl technology, applied in oil-based lubricants and their application fields, can solve the problem of high production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] It is obtained by mixing 50 parts by mass of cottonseed oil and 50 parts by mass of zinc octyl alkyl dithiophosphate.

Embodiment 2-6

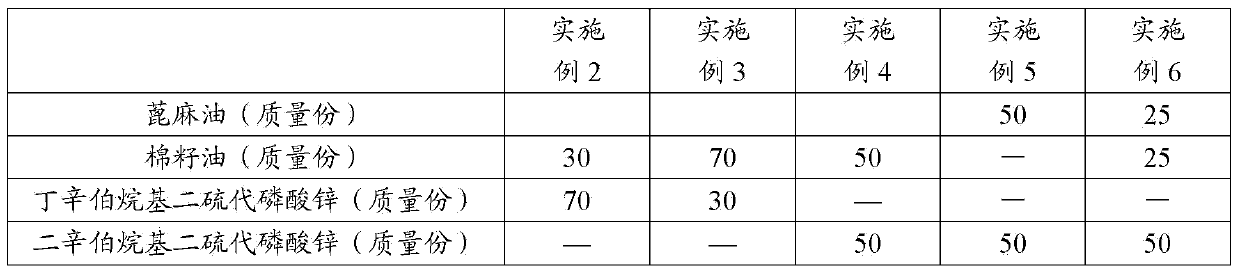

[0027] The preparation method is the same as in Example 1, and the amounts of each material are shown in the table below.

[0028]

[0029] Lubrication Performance Evaluation

[0030] Measure 300mL of distilled water, add 36g of sodium bentonite for drilling fluid test, stir at a high speed of 11,000r / min for 20min, and maintain in a closed container at room temperature for no less than 16h to prepare a prehydrated bentonite slurry with a soil content of 12%. ; Prepare 2 parts of polymer slurry: Measure 250mL of seawater, add 56g of pre-hydrated bentonite slurry, 0.6g of caustic soda, 0.6g of soda ash, 0.9g of PF-PAC LV, 0.9g of PF-XC and 9g of calcium soil, and add weight with barite to 1.2g / cm 3 , stir at a high speed of 11000r / min for 20min, after curing for 4h, stir at a high speed of 11000r / min for 20min; add 6g of the oil-based lubricant prepared in each embodiment to one of the muds, and use a speed of 11000r / min Stir at high speed for 20 minutes, which is the poly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com