Harmless pure gas extraction method and double-furnace folding garbage combustion furnace used in same

A double-furnace stacking and waste burning technology, which is applied in the direction of incinerators, combustion methods, and combustion types, can solve the problems of large space occupation, complicated equipment, and waste of energy, and achieves reduced space occupation, compact equipment structure, and improved efficiency. The effect of flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

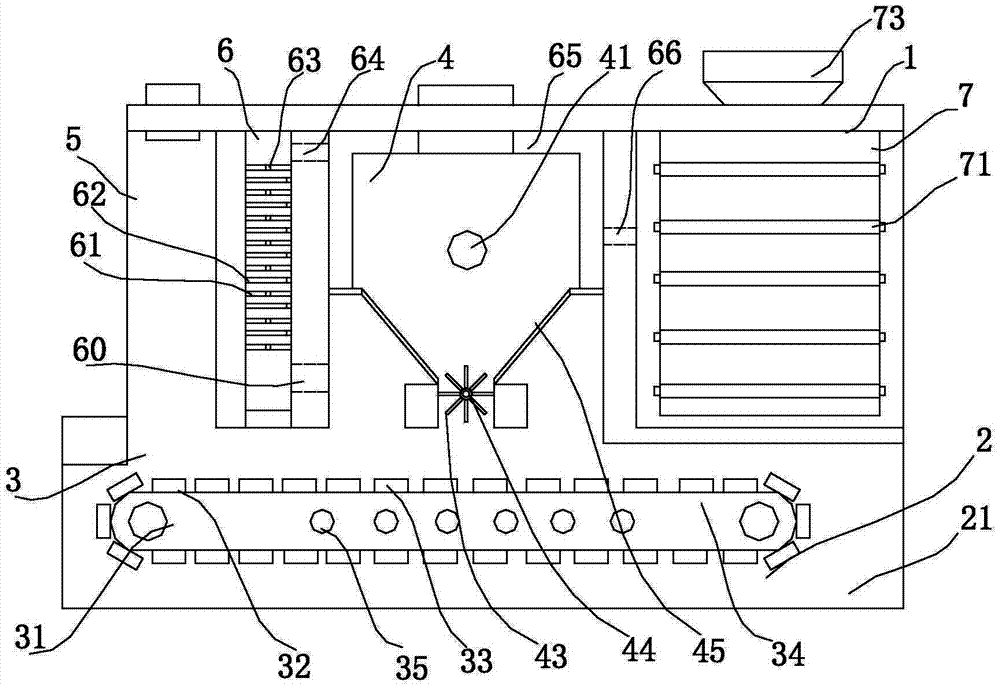

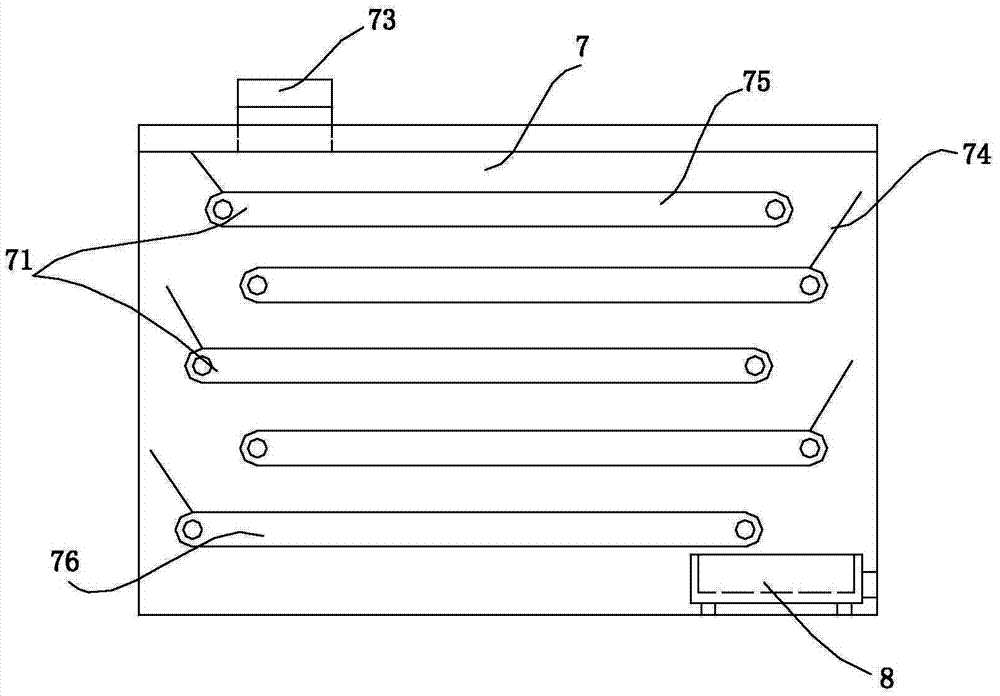

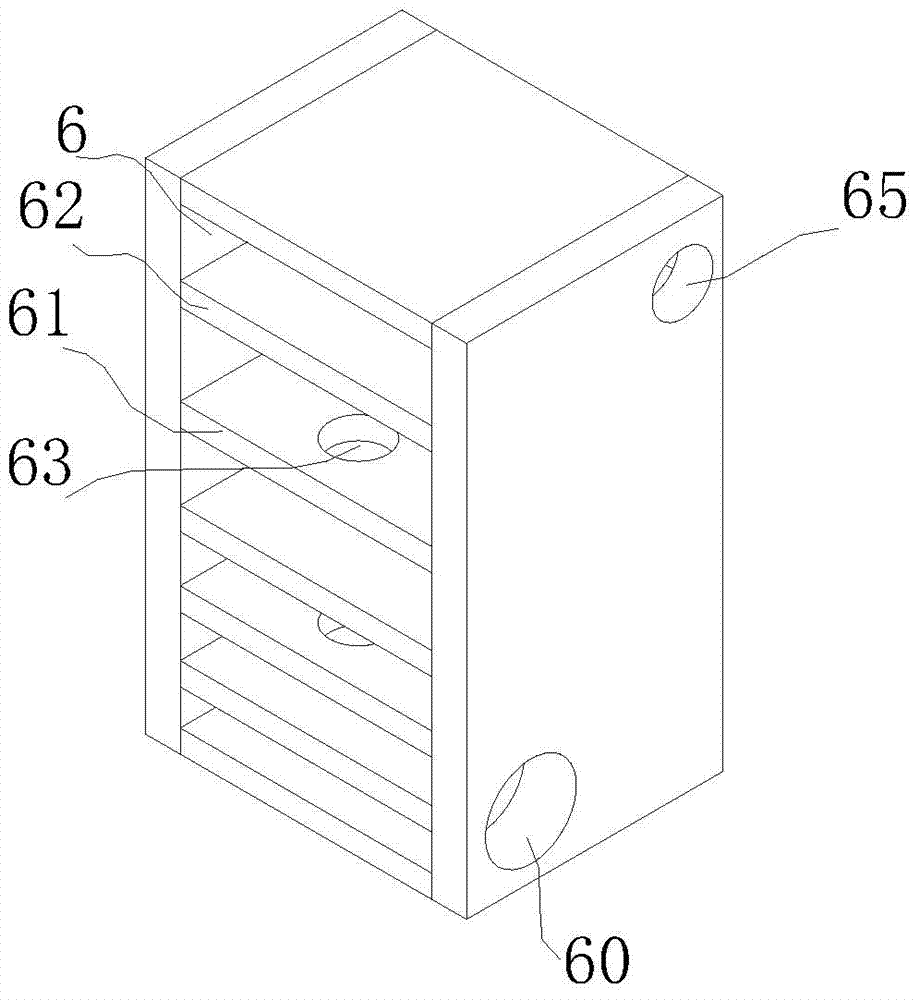

[0027]Example. A method for harmlessly extracting pure gas, which uses the main combustion gasification furnace 2 to burn the garbage, uses the high-temperature gas generated by the combustion to dry the garbage before entering the garbage carbonization furnace 4, and uses the high-temperature flame generated by the combustion to enter the garbage carbonization furnace The garbage in the furnace 7 is roasted and dry-distilled to generate dry distillation gas, which is then extracted through a negative pressure container for storage.

[0028] The rubbish before entering the rubbish retort furnace 4 is dried, and the rubbish is synchronously transported to the rubbish retort furnace through the closed rubbish transfer chamber 7, and the high-temperature gas is input into the rubbish transfer chamber 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com