A kind of composite microbial activator and its preparation method and application

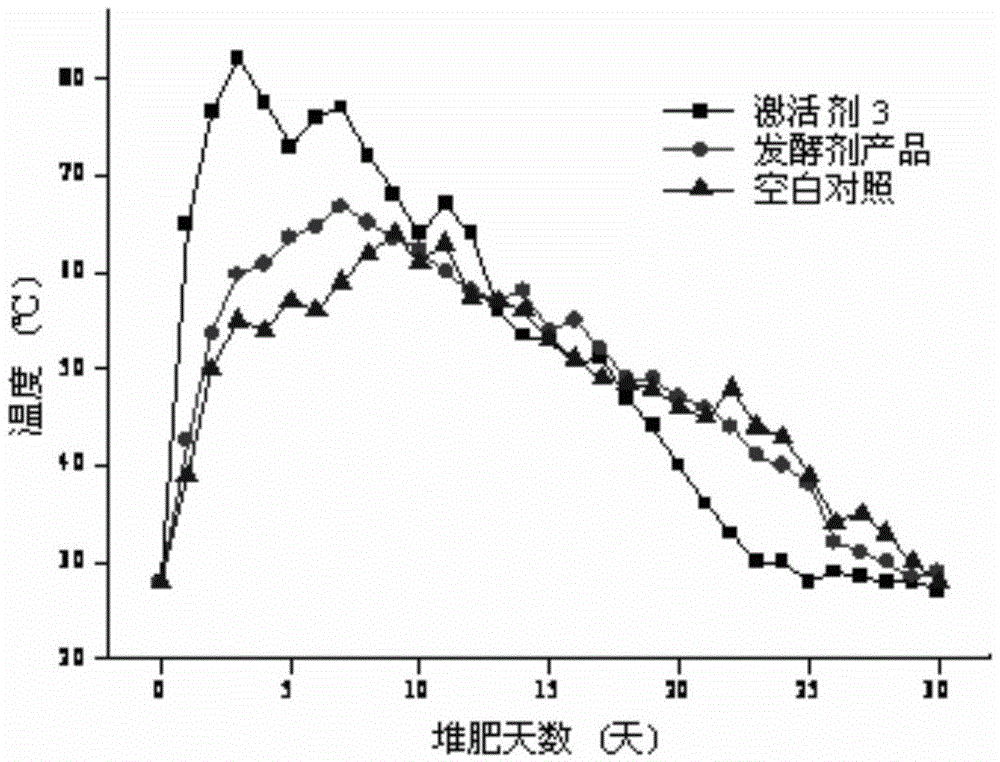

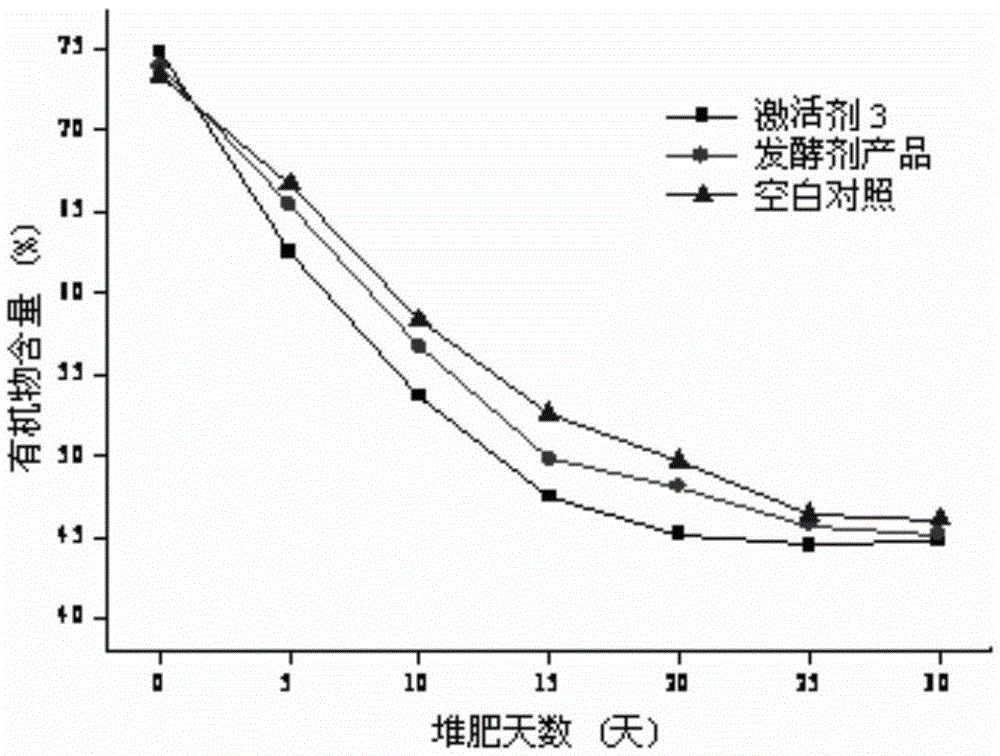

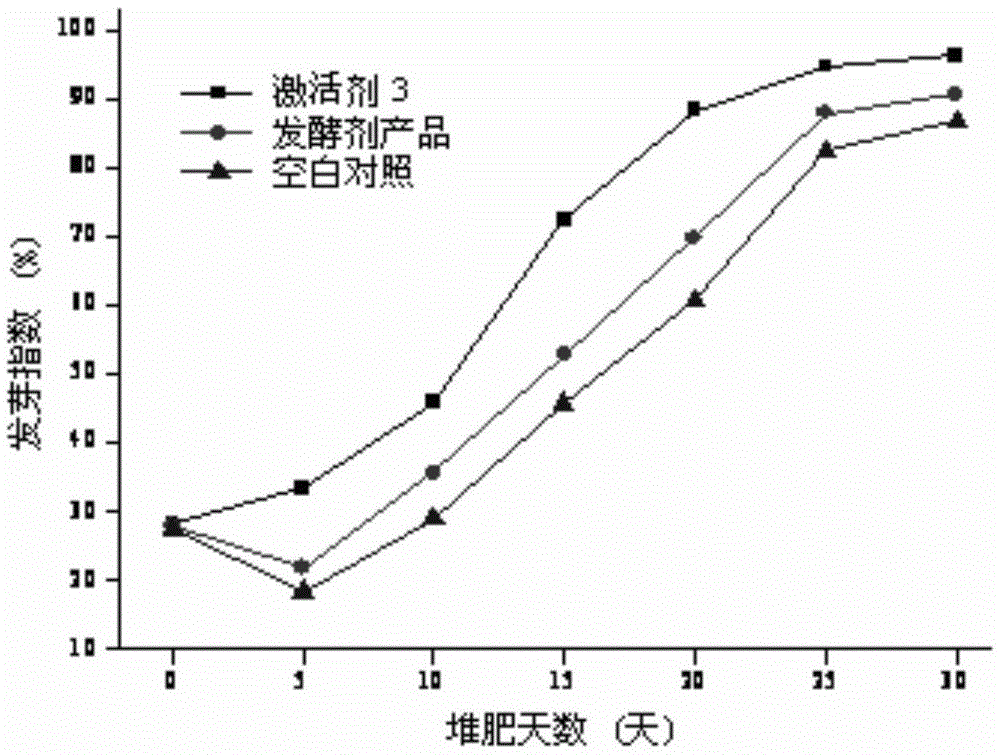

A technology of composite microorganisms and microbial agents, applied in the field of environmental microorganisms, can solve the problems that have not been seen in public reports, and achieve the effect of promoting high-temperature fermentation process, improving compost quality, and promoting composting process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Activation of embodiment 1 microbial strain

[0039] 1) Transfer the slant of the UTM401 production strain stored at 4°C to the LB medium plate, and cultivate it at 30°C until it becomes abundant.

[0040] 2) Transfer the slants of UTM501 and UTM601 production strains stored at 4°C to LB medium plates, and culture them at 55°C until they become rich.

[0041] 3) Transfer the UTM01, UTM02, and UTM03 production strains stored at 4°C to the LB medium plate, and culture them at 60°C, 60°C, and 65°C until they are abundant.

[0042] 4) Transfer the UTM01, UTM02, and UTM03 production strains stored at 4°C to the LB medium plate, and cultivate them at 65°C until they become rich.

[0043] 5) Transfer the UTM01, UTM02, and UTM03 production strains stored at 4°C to the LB medium plate, and culture them at 60°C, 65°C, and 65°C until they are abundant.

[0044] 6) Transfer the slant of the UTM801 production strain stored at 4°C to the improved YTPG medium plate, and cultivate it...

Embodiment 2

[0045] The preparation of embodiment 2 microbial fermentation seed liquid

[0046] 1) Preparation of UTM401 fermented seed solution

[0047] Use a sterile glass spatula to transfer all the UTM401 colonies that were activated and cultured on the LB plate to a 5000ml Erlenmeyer flask containing 2000ml LB liquid medium, and shake and culture it on a shaker at 30°C at a speed of 160r / min for 3 days. At this time, the OD600 was 1.8, and the cultivation was stopped, and this was the primary fermentation seed liquid.

[0048] Inoculate the primary fermentation seed liquid into the fermentation seed tank to carry out fermentation culture. Fermentation conditions are: inoculation amount (v / v) 10%, canned amount (v / v) 80%, intermittent ventilation and stirring: every 4 hours aeration for 10 minutes, ventilation rate (v / v) 1:1, every Stir for 10 minutes every 8 hours, rotate at 160 rpm, and cultivate at 30°C for 3 days. The OD600 was detected to be 2.5, and the cultivation was stopped....

Embodiment 3

[0058] The preparation of embodiment 3 fermentation activators

[0059] Take cassava skin, cassava distiller's grains, pig manure, plant ash, and cornmeal and mix them in a weight ratio of 2:2:2:0.8:0.2, so that the height of the fermentation pile is 1.4 meters, and the fermentation temperature is checked at multiple points every day. According to the temperature change, inoculate each fermentation liquid equivalent to 0.3% of the dry weight of the initial material. Before inoculation, use an appropriate amount of cornmeal to absorb each fermentation seed liquid, and stir to mix evenly after inoculation. The inoculation time of each bacteria is: inoculate UTM501 and UTM601 when the highest fermentation temperature reaches 55°C, inoculate UTM01 when the highest fermentation temperature reaches 65°C, inoculate UTM801 when the highest fermentation temperature reaches 70°C, and maintain at 70°C for 2 days; Inoculate UTM401 when the maximum fermentation temperature drops to 38°C, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com