A kind of corrosion-resistant high anti-extrusion petroleum casing and its production method

A kind of oil casing, high resistance technology, applied in the direction of casing, drill pipe, earthwork drilling and mining, etc., can solve the problems of poor impact toughness and corrosion resistance in the weld zone, and achieve high and uniform anti-external pressure crushing strength Consistent strength and toughness, the effect of saving procurement costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention is described in further detail below in conjunction with accompanying drawing:

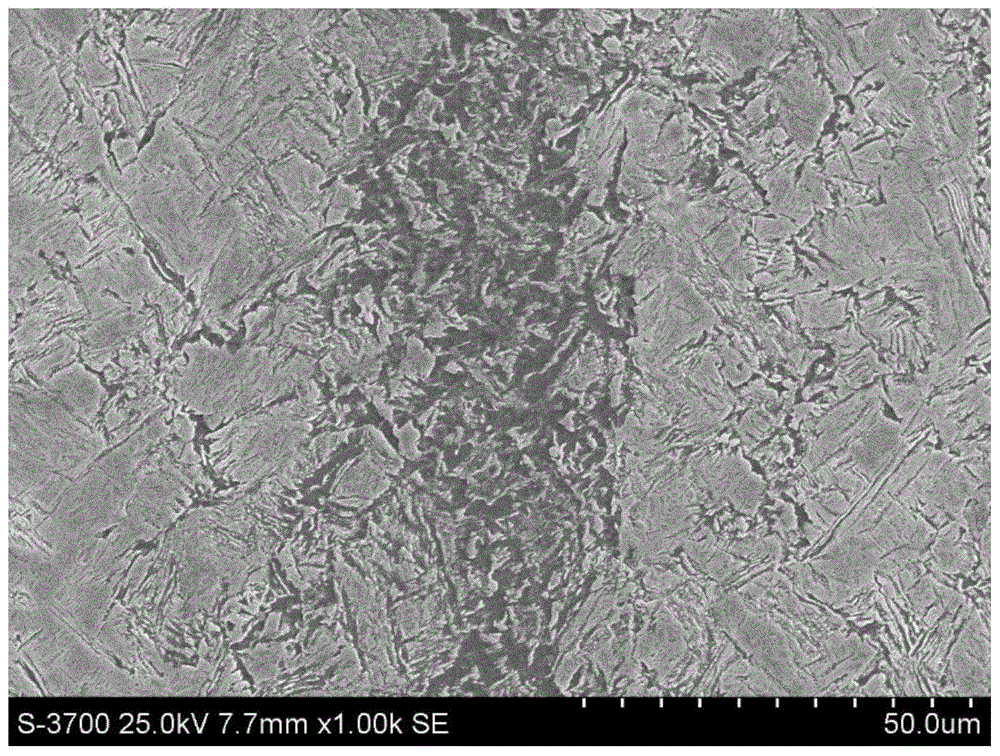

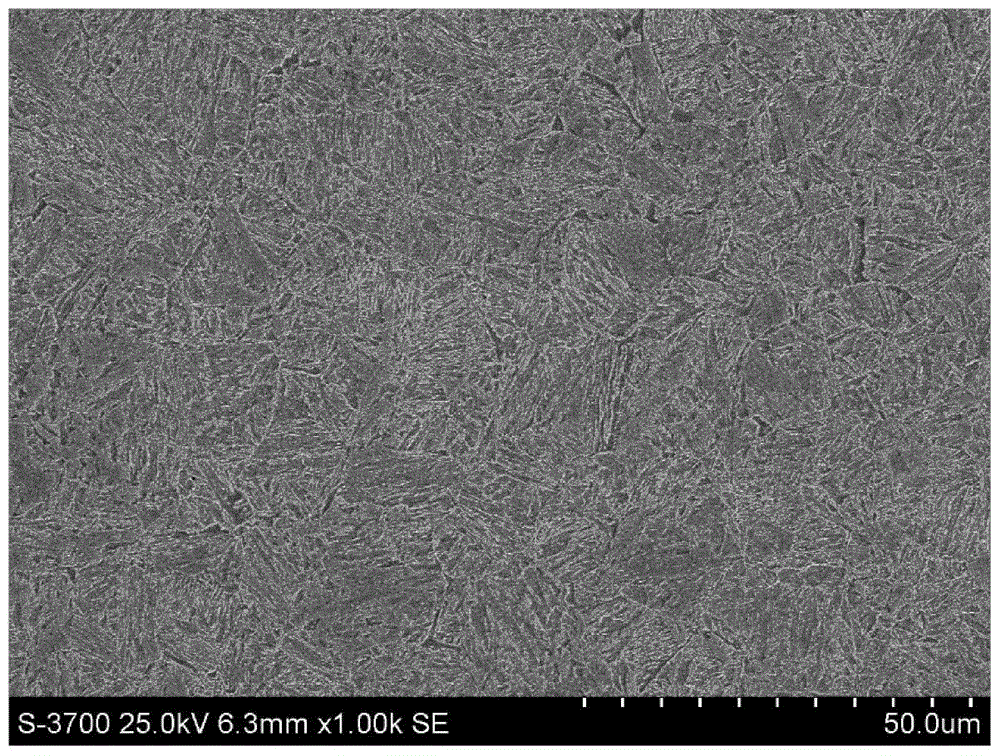

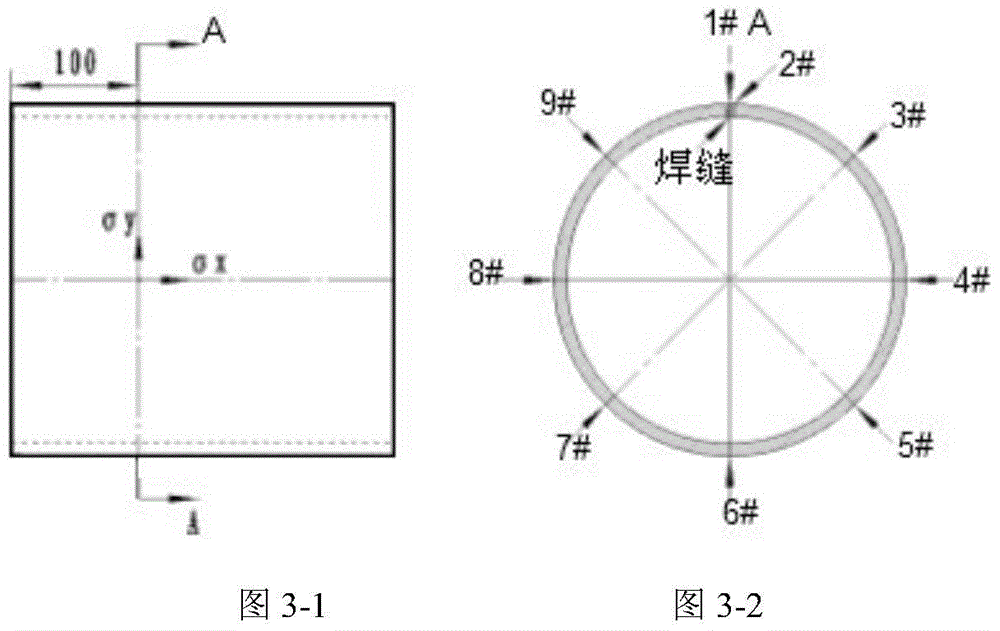

[0040] 1) see figure 1 , 2 , 3-1, 3-2, 4, 5, 6, 7, 8, the chemical compositions of the embodiments of the present invention and comparative examples are shown in Table 1.

[0041] Table 1 embodiment and comparative example chemical composition (wt %)

[0042]

[0043] 2) The geometric accuracy control range of the bushing is as follows:

[0044] Take the casing with the specification of Φ139.7mm×9.17mm as an example. Outer diameter: 139.65~139.98, outer diameter out of roundness: <0.3%; wall thickness: 9.15~9.33, wall thickness unevenness: <2.0%.

[0045] 3) The casing adopts welding seam rolling and annealing treatment, and the annealing temperature is 850-1000°C.

[0046] 4) The casing adopts the medium frequency induction heating method, heats the HFW welded pipe at a heating rate of 20-60°C / s to above the Ac3 temperature, and then enters the rolling unit at...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| residual stress | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com