Overground operating string delivery mechanism

A technology for conveying devices and operating strings, which is applied in the direction of drilling pipes, casings, and drilling equipment. It can solve problems such as large inertial force, time-consuming and labor-intensive efficiency, and unsafe human body, and achieve reduced contact, good compatibility, and enhanced safety. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

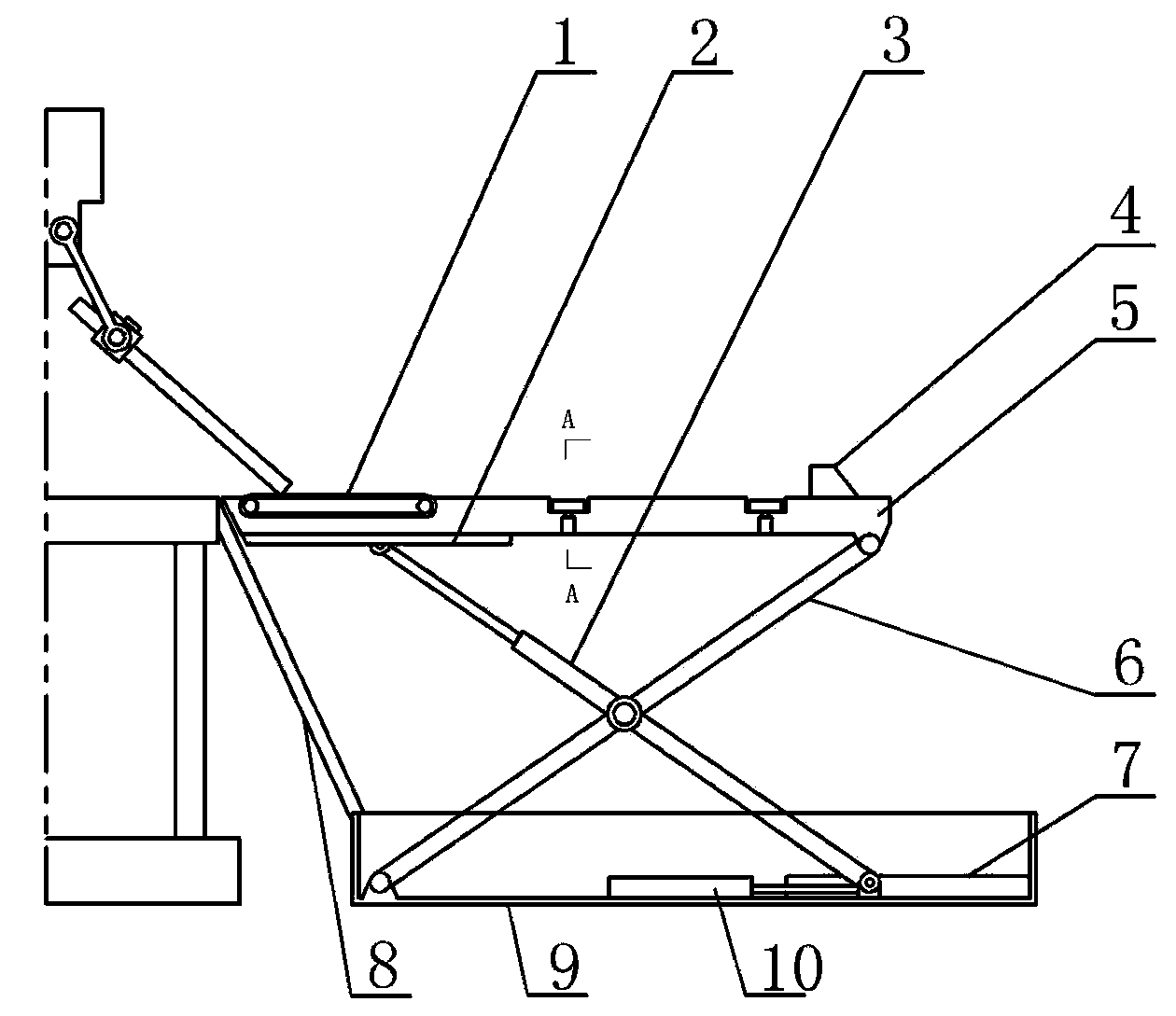

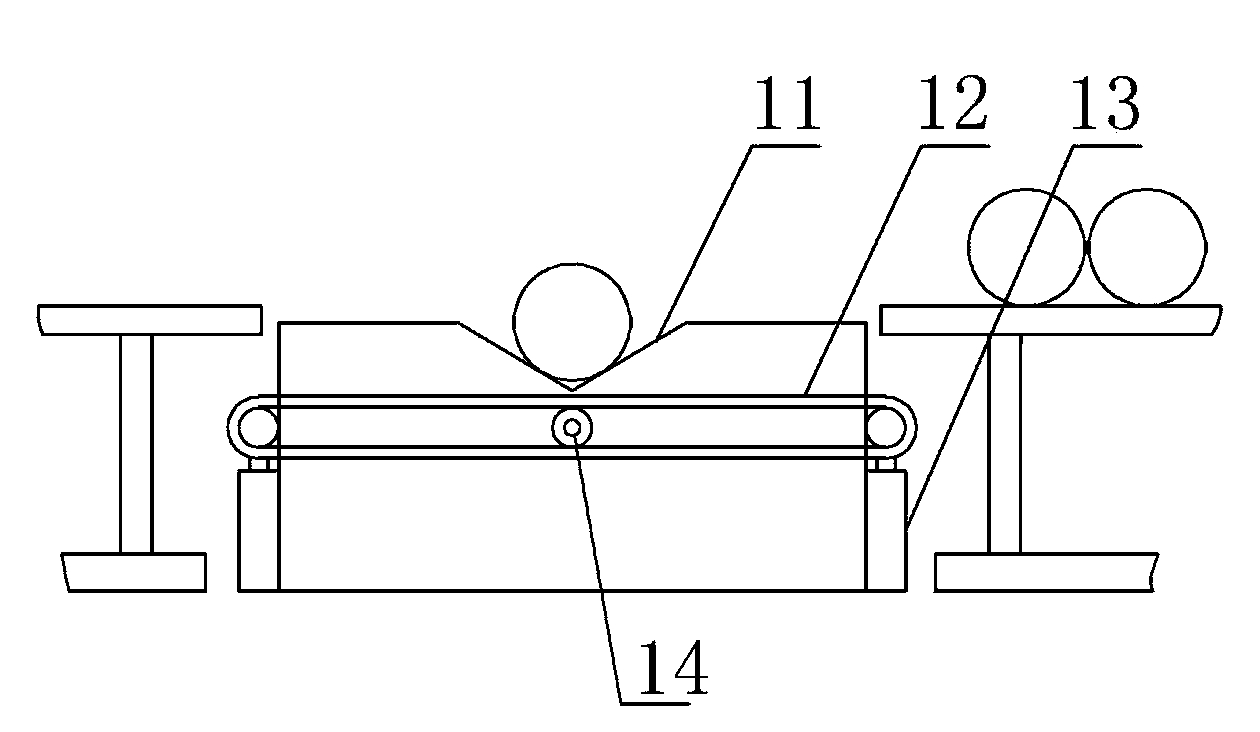

[0016] Embodiment 1: with reference to attached figure 1 , image 3 and Figure 4 , the lower end of the ramp 8 of the uphole operation pipe string delivery device of the present invention is connected to the catwalk support 9, the catwalk body 5 is above the catwalk support 9, and the upper end surface of the catwalk body 5 is horizontally provided with a V-shaped slideway 11. Drill block car 4 can slide in V-shaped slideway 11. A lifting support leg 6 and a sliding support leg 3 are connected between the catwalk body 5 and the catwalk support 9 . The two ends of the lifting support leg 6 are respectively hinged with the catwalk support 9 and the catwalk body 5, and the lifting support leg 6 and the sliding support leg 3 are hinged in an X shape at their respective midpoints. One end of the sliding support leg 3 slides in the lower track 7 , and the other end of the sliding support leg 3 slides in the upper track 2 and is connected to the horizontal hydraulic cylinder 10 ....

Embodiment 2

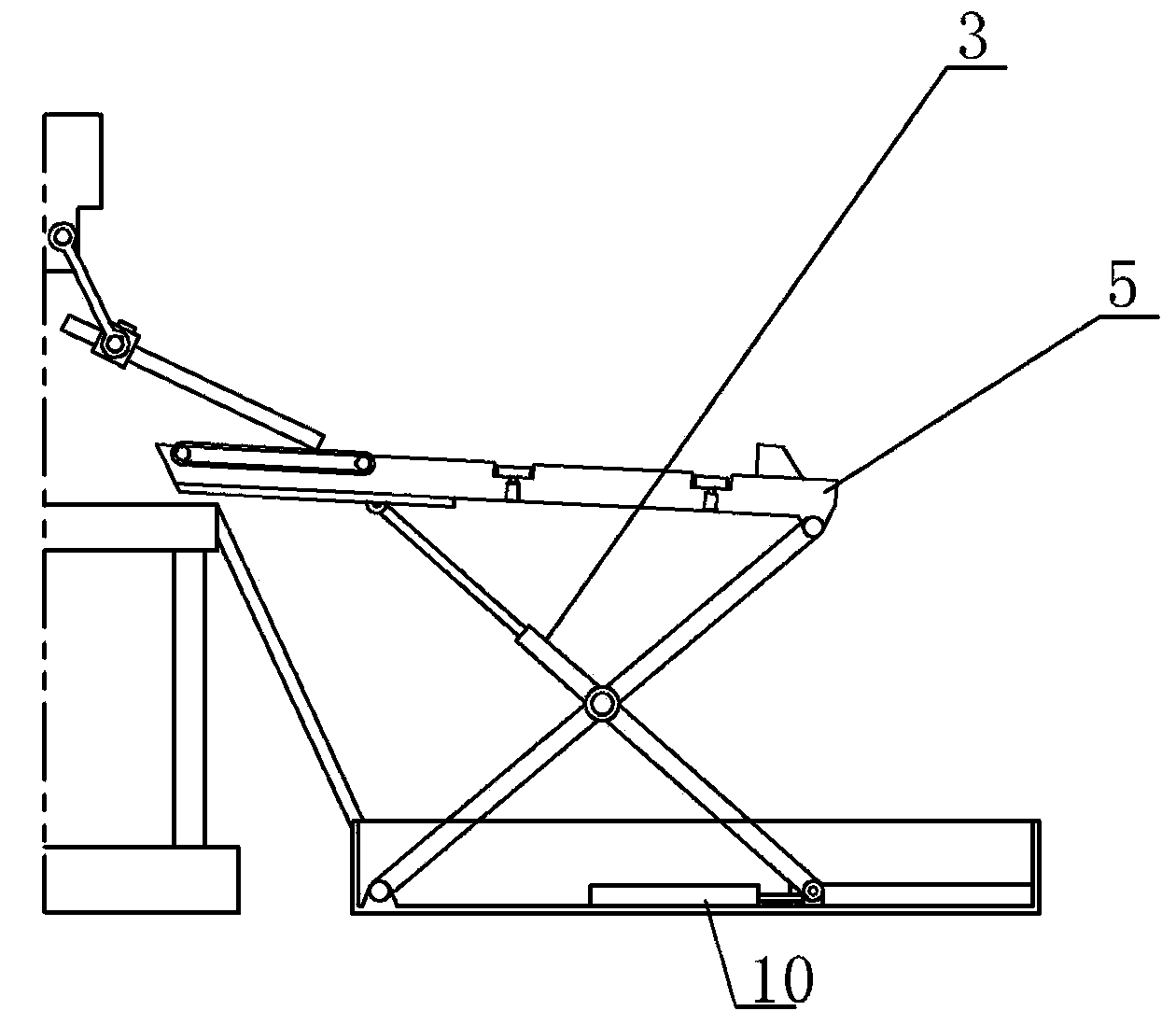

[0020] Embodiment 2: refer to figure 2 , on the basis of the structure of the uphole operation pipe string delivery device in Embodiment 1, the end of the sliding support leg 3 close to the catwalk body 5 is a telescopic arm with a built-in hydraulic cylinder.

[0021] The process of sending up the pipe string: first, the catwalk body 5 is in the initial position, the pipe row conveyor belt 12 moves the pipe string on the pipe rack to the V-shaped slideway 11, and the drilling block 4 moves to the pipe string along the V-shaped slideway And against one end of the pipe string. Then the telescopic arm extension of the sliding support leg 3 makes the end of the catwalk body 5 near the drill floor perk, and the catwalk body 5 is in an inclined state. The horizontal hydraulic cylinder 10 works, and the catwalk body 5 starts to lift. When the end of the catwalk body 5 close to the drill floor rises above the drill floor and approaches the wellhead, the lifting stops. At this time,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com