A water-cooled heat dissipation module system for engineering vehicles

A technology for water-cooled heat dissipation and engineering vehicles, which is applied in the directions of fluid pressure actuation system components, engine cooling, gear lubrication/cooling, etc. It can solve problems such as difficult working temperature requirements, so as to improve flexibility, improve vehicle operating efficiency and reliability performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

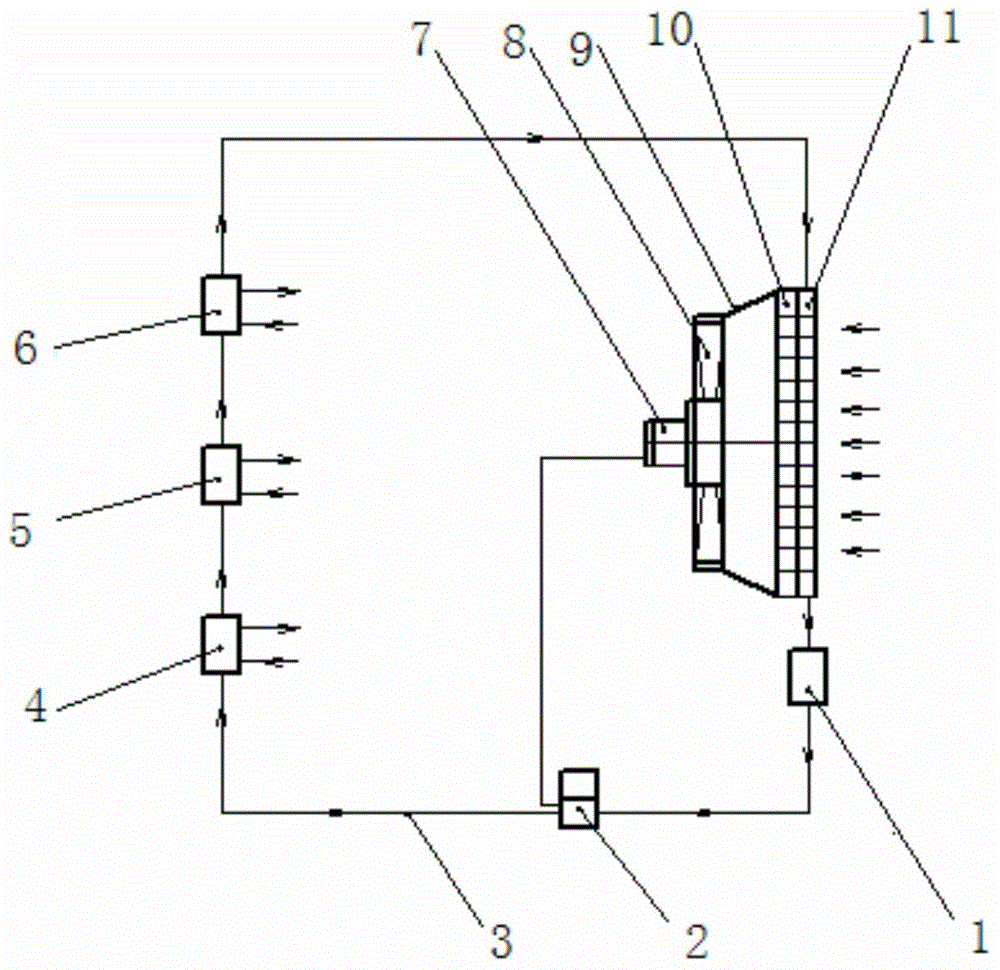

[0027] Below in conjunction with accompanying drawing, the present invention is described in detail:

[0028] In view of the requirements of the multi-heat source systems of engineering vehicles for their respective operating temperature characteristics, in order to avoid the high temperature of each system affecting the efficient and reliable operation of the vehicle system, the present invention designs a set of engineering vehicle water cooling and heat dissipation module systems to achieve high efficiency of the heat of each system heat dissipation.

[0029] Connect the heat source representing the engine charge air of the engineering vehicle to the engine charge air cooling device 4, connect the heat source representing the hydraulic system of the engineering vehicle to the hydraulic oil cooling device 5 of the hydraulic system of the vehicle, and connect the heat source representing the transmission system of the engineering vehicle to the vehicle In the transmission oil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com