Wind generating set blade load measurement device and measurement method thereof

A wind turbine and load measurement technology, which is applied in the direction of measuring the change force of the optical properties of the material when it is stressed, can solve the problems of easy failure, difficulty in large-capacity network measurement, complicated sensor wiring, etc., and achieve accurate Calculation, easy to reuse the effect of network measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to describe the technical content, structural features, goals and effects of the present invention in detail, the following examples are given and described in detail with accompanying drawings.

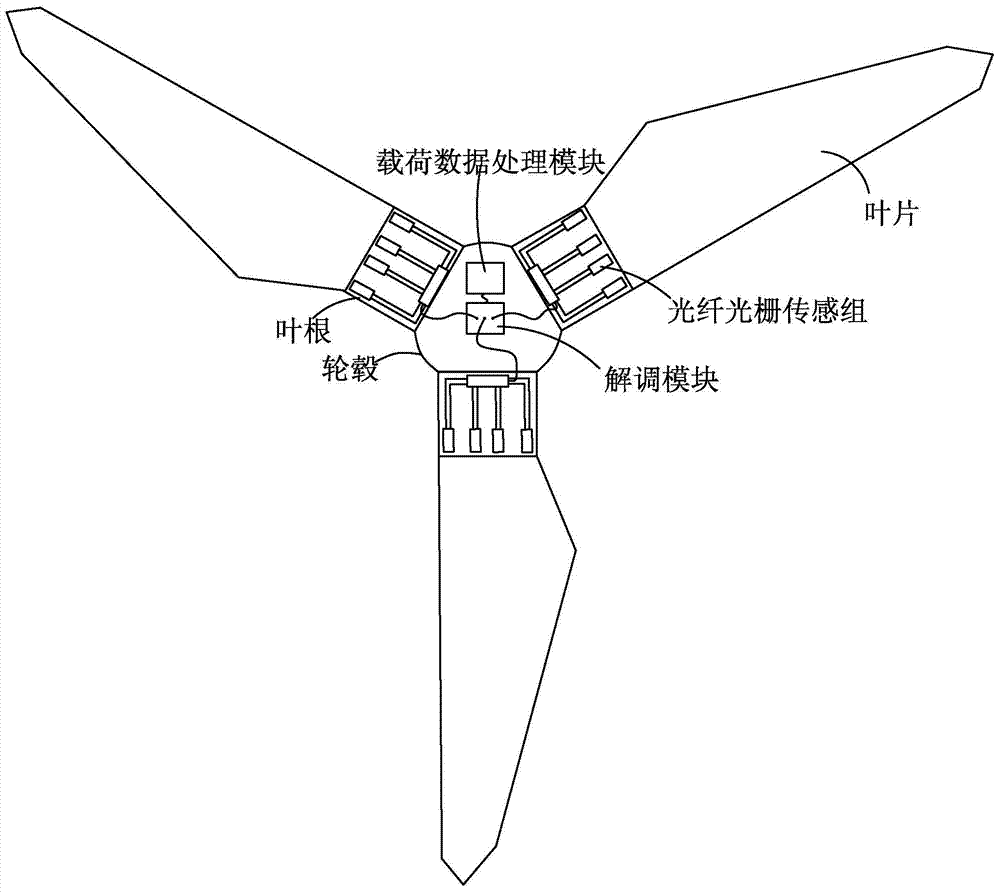

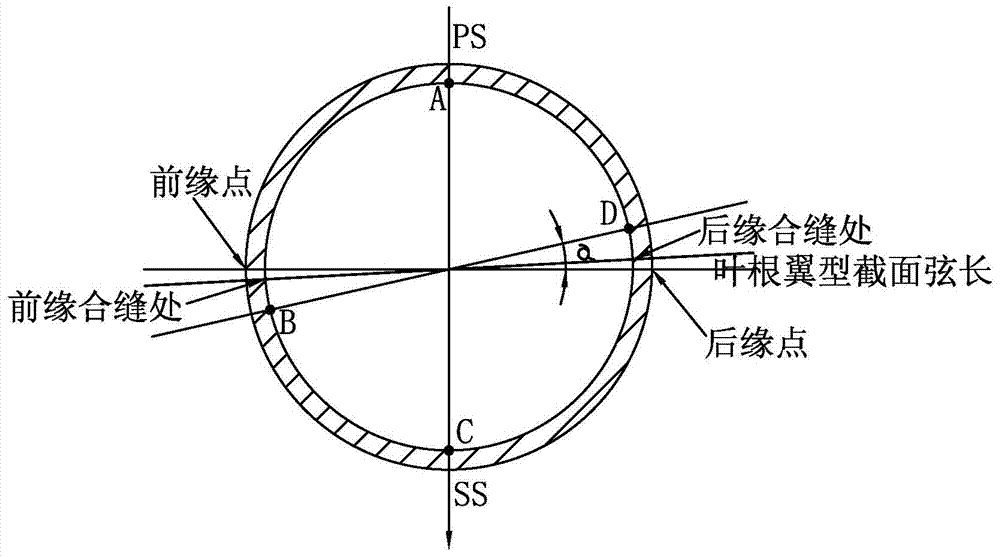

[0028] see figure 1 , figure 2 and image 3 According to the present invention, a load measuring device for blades of a wind power generating set includes at least three fiber grating sensor arrays, a demodulation module and a load data processing module.

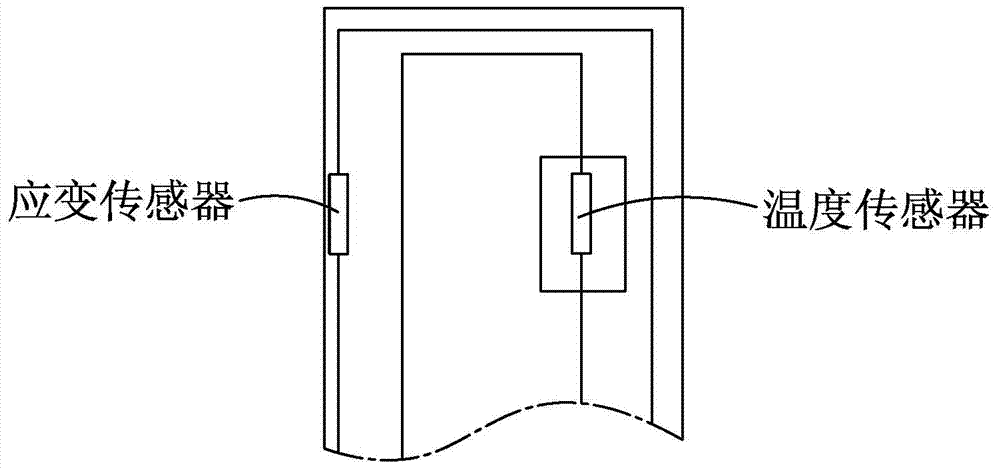

[0029] Each fiber grating sensor array is installed on the inner surface of the blade root of the wind turbine, and each fiber grating sensor array is composed of at least four fiber grating sensor groups in series, and each fiber grating sensor group consists of a strain sensor and a temperature sensor. Each fiber grating sensor group is composed of a strain sensor and a temperature sensor. The strain sensor is used to measure the corresponding strain of the blade under load, and the temperature sensor is used...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com