Wind power master control cabinet heat management analysis and optimization method based on finite element method

A technology of finite element method and optimization method, which is applied in the fields of electrical digital data processing, special data processing applications, instruments, etc., can solve the problems of inability to obtain calculation results, limited analytical method solving ability, high cost, and achieves large adaptability and high cost. Solving power, large degrees of freedom and flexibility, the effect of accurate calculation results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

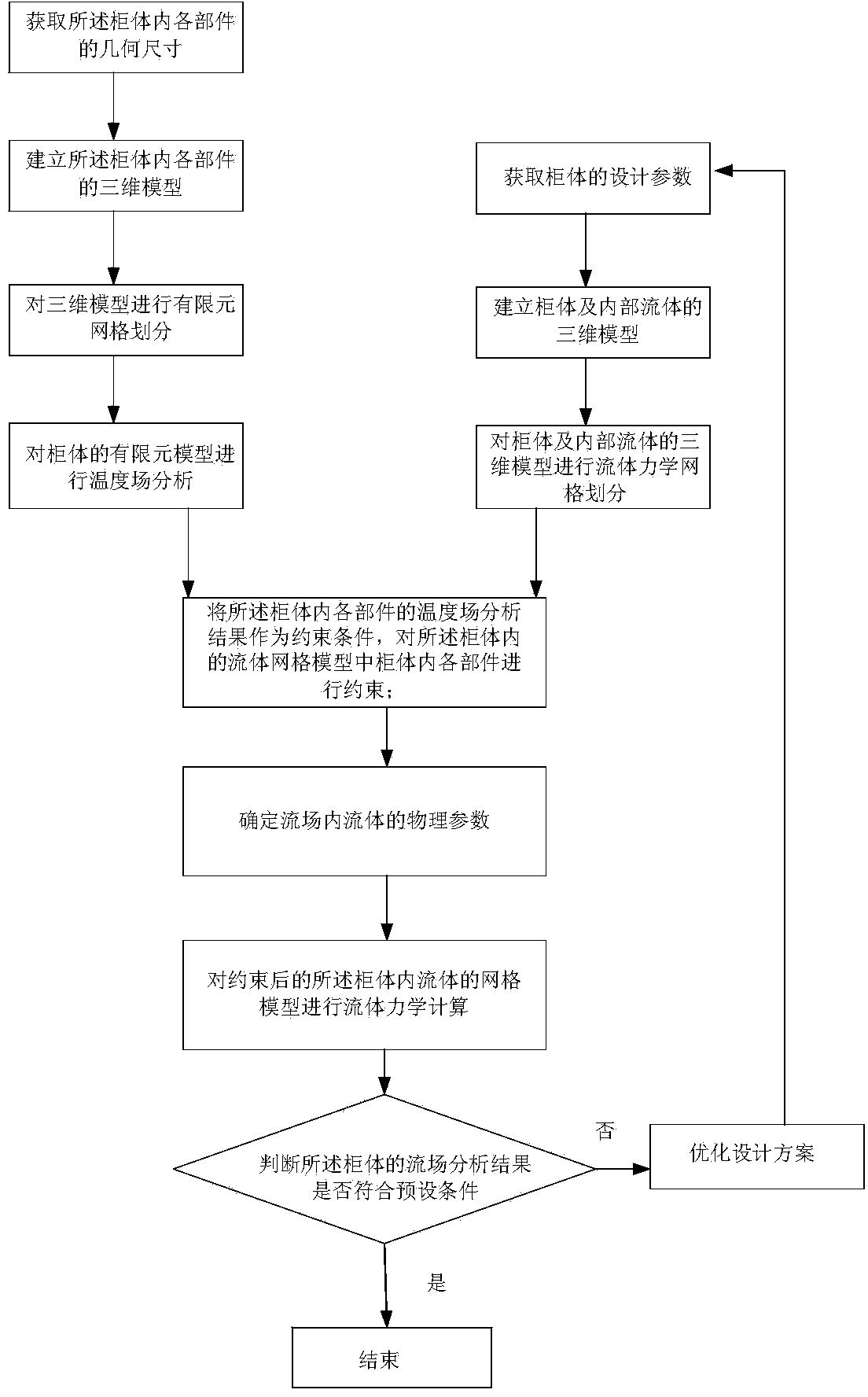

[0032] figure 1 It is a flowchart of a thermal management analysis and optimization method for a main control cabinet of wind power based on the finite element method provided by the embodiment of the present application.

[0033] like figure 1 As shown, the method includes the following steps:

[0034] Step S101: Obtain the material properties of the cabinet and the parameters of the internal circuit breaker and relay;

[0035] In the step S101, the parameters include: geometric dimensions, thermodynamic properties, initial temperature, and heat generation rate of components such as circuit breakers and relays during operation.

[0036] Step S102: Establish a three-dimensional model inside the wind power main control cabinet.

[0037] Accordi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com