Composite reagent for tape casting, fuel cell and preparation method of fuel cell

A technology of tape casting and compounding reagents, which is applied to battery electrodes, circuits, electrical components, etc., can solve the problems of complex process, increase the lubricity and ductility of the casting process, and affect the performance, so as to simplify the preparation process and shorten the production. time, the effect of increasing the firing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

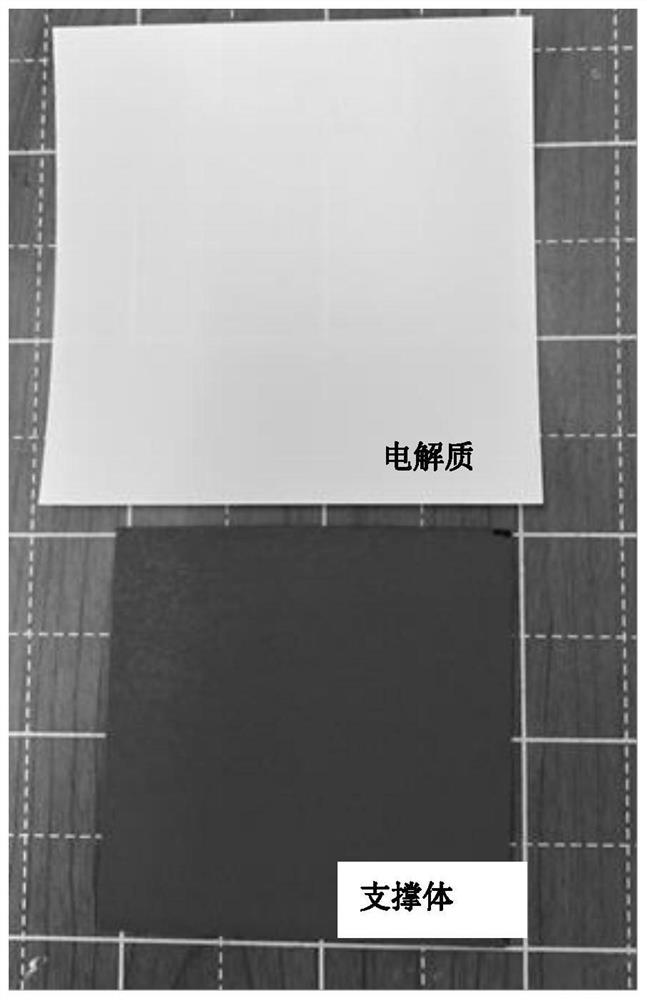

[0083] This embodiment provides a reagent for tape casting, the reagent is a composite solvent, a liquid composite binder and a composite plasticizer;

[0084] Based on the total mass of the composite solvent as 100%, the composite solvent contains 2% of the total mass of the dispersant, alcohol and toluene are mixed in a ratio of 1:1.5 and the total amount of the two is 98%; the dispersant is fish oil;

[0085] Based on the total mass of the composite liquid binder as 100%, the composite liquid binder comprises 20% of the total mass of the solid binder powder, 80% of the composite solvent; the solid binder powder is polyvinyl butyral;

[0086] Based on the total mass of the composite plasticizer as 100%, the composite plasticizer includes 45% of a first-class plasticizer, and 55% of a second-class plasticizer; the first-class plasticizer is diformic acid ester; the second type of plasticizer is polyglycol; this embodiment also provides a fuel cell and a preparation method th...

Embodiment 2

[0102] This embodiment provides a reagent for tape casting, the reagent is a composite solvent, a liquid composite binder and a composite plasticizer;

[0103] Based on the total mass of the composite solvent as 100%, the composite solvent contains 2% of the total mass of the dispersant, alcohol and toluene are mixed in a ratio of 1:1.5 and the total amount of the two is 98%; the dispersant is fish oil;

[0104] Based on the total mass of the composite liquid binder as 100%, the composite liquid binder comprises 20% of the total mass of the solid binder powder, 80% of the composite solvent; the solid binder powder is polyvinyl butyral;

[0105] Based on the total mass of the composite plasticizer as 100%, the composite plasticizer includes 45% of a first-class plasticizer, and 55% of a second-class plasticizer; the first-class plasticizer is diformic acid ester; the second type of plasticizer is polyglycol; this embodiment also provides a fuel cell and a preparation method th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com