servo motor

A servo motor and motor shaft technology, applied in the field of servo motors, can solve the problems of reducing production efficiency, increasing the diameter of the shaft, reducing the rigidity of the casing, etc., and achieve the effects of increasing manufacturing costs, shortening the length and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

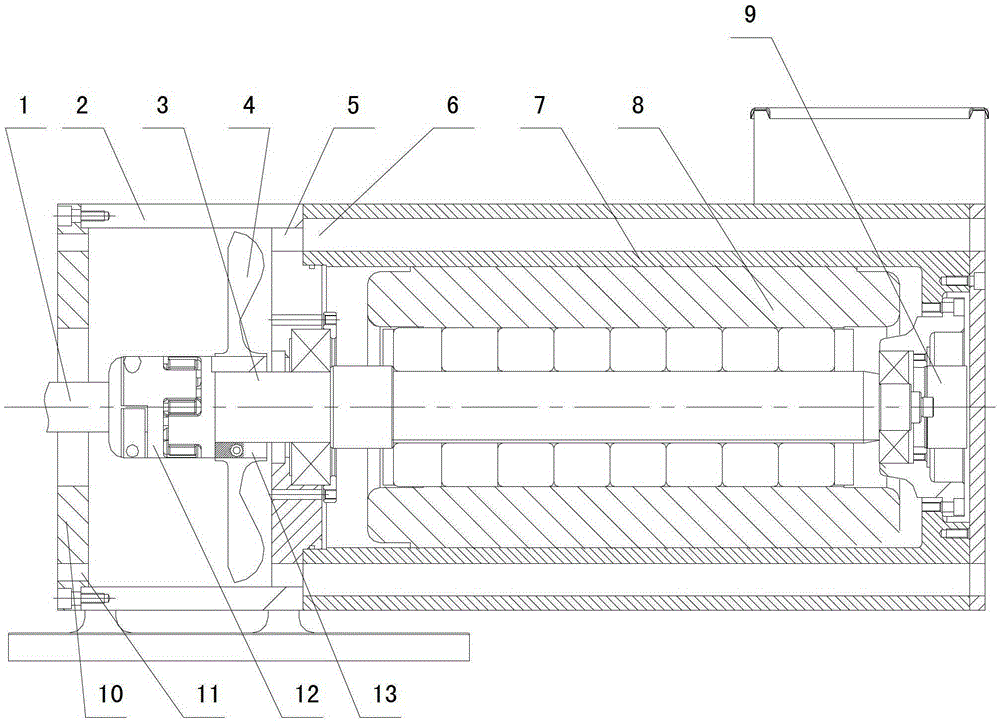

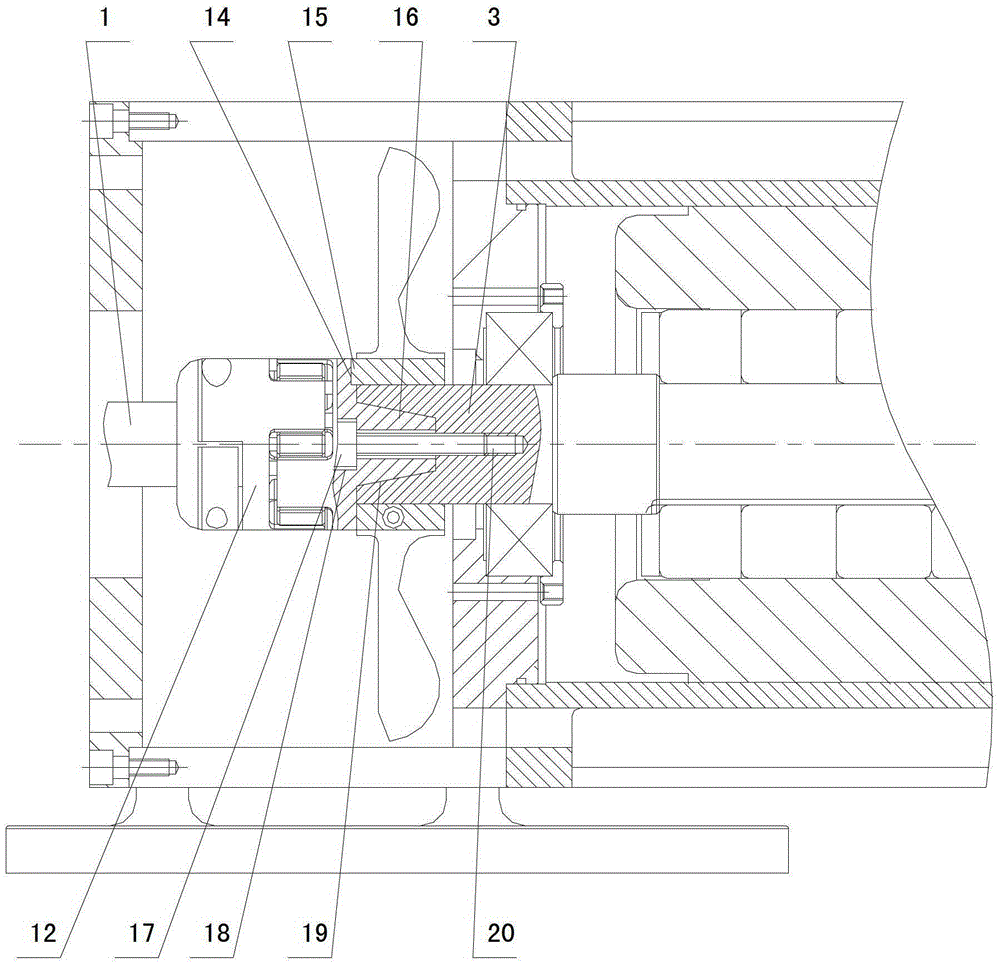

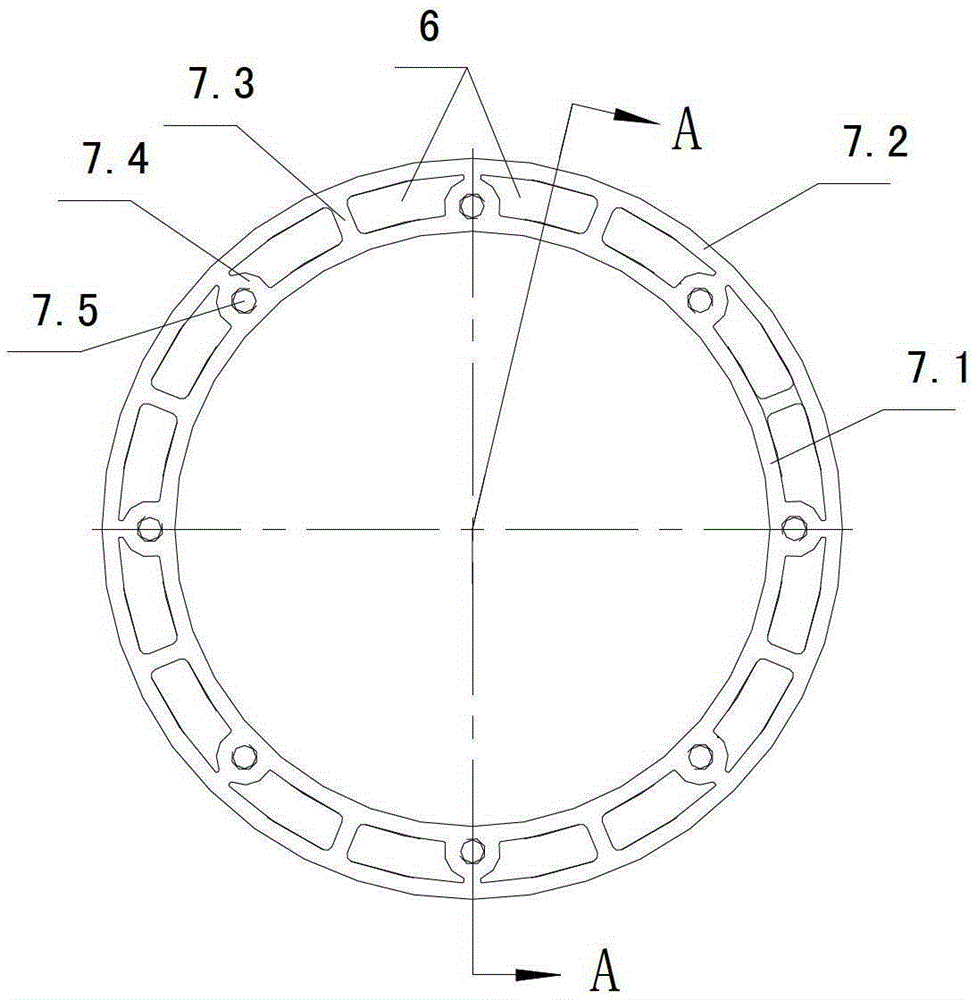

[0028] Depend on Figure 1 ~ Figure 4 As can be seen from the shown structural diagram of the servo motor of the present invention, it includes a motor 8, an encoder 9, a fan 4, an air guide sleeve 7 and a shaft coupling connecting the motor shaft 3 and the input shaft 1 of the working part (in this embodiment, the working Component is an oil pump), the motor 8 is located in the wind guide sleeve 7, and the end of the motor shaft 3 extending out of the motor housing is the output end, and the other end is the tail end, and the encoder 9 is installed on the tail end of the motor shaft 3. The fan 4 is fixedly connected to the output end of the motor shaft 3, the coupling is an elastic coupling 12 and is located between the output end of the motor shaft 3 and the end face of the input shaft 1 of the working part, the elastic coupling 12 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com