Stereoscopic planting greenhouse with two layers and multiple zones

A technology of three-dimensional planting and greenhouses, applied in botany equipment and methods, greenhouse cultivation, climate change adaptation, etc., can solve problems such as difficult industrial production, poor heat preservation, increased production costs, etc., to achieve easy industrial production, improve growth quality, The effect of saving water and electricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

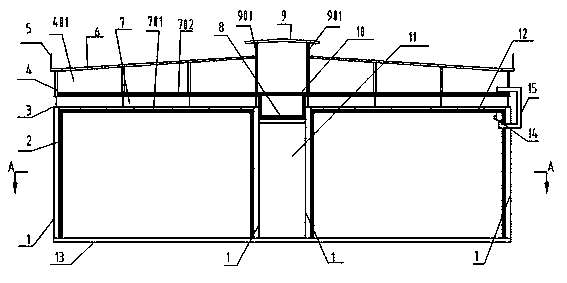

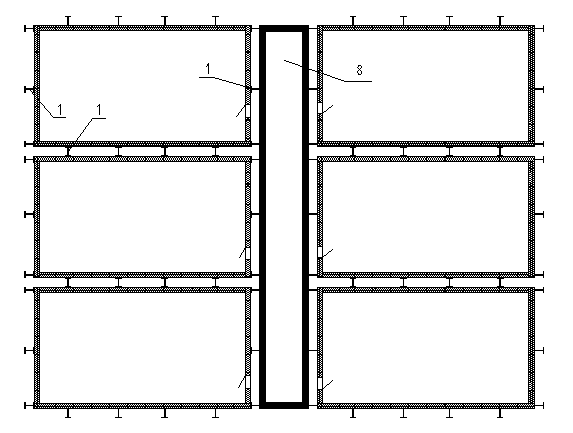

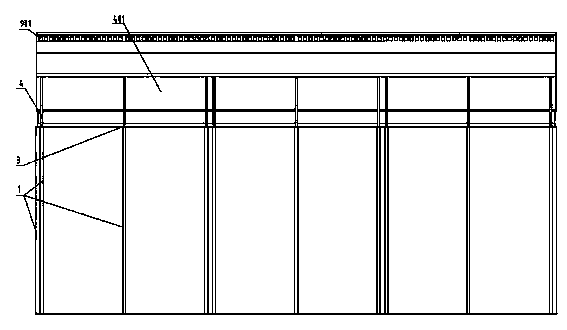

[0027] As shown in the figure, the three-dimensional planting greenhouse with two floors and multiple zones is composed of the main frame of the three-dimensional greenhouse by the steel structure members that play a connecting role, the column 1, the beam 7 and the roof 6. vertical column) setting, this specific embodiment has 13 rows and 12 columns in total, each column 1 is provided with a supporting connector 3 and an extension 4, and the supporting body 3 can be any structure used for connection and support, such as It can be a steel plate welded on the column 1, or a boss arranged on one side of the column 1, etc.; the opposite supporting connector 3 is provided with a beam 7, and the beam 7 is connected with the column 1 to form an integral structure. The beam 7 is provided with a concrete Board 702, the concrete board 702 divi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com