A kind of drum type granulation method and granulation device thereof

A drum-type and granulation technology, applied in the chemical industry, can solve the problems of product decline and raw materials that are not packaged as granules, and achieve the effect of reducing operating costs, reducing investment costs and simplifying process flow.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Embodiment 1: stearic acid granulation

[0017] The method for stearic acid granulation of the present invention may further comprise the steps:

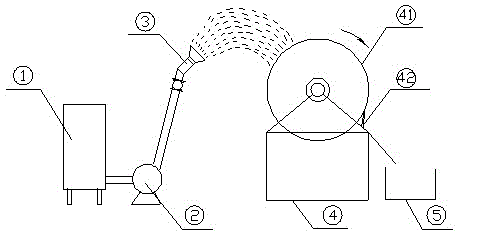

[0018] 1) Put 200KG liquid stearic acid in the storage tank 1, keep the steam at 80°C, install the high-temperature liquid pump 2 from the bottom of the storage tank 1, connect the outlet of the high-temperature liquid pump 2 to the nozzle 3, and adjust the nozzle 3 to 45 degrees upward ;

[0019] 2) if figure 1 As shown, after the installation of the subsequent roller slicer 4 and the collection bin 5 is completed, the circulating cooling water (8° C.) of the roller slicer 4 is turned on for 10 minutes, and then the roller slicer 4 is turned on.

[0020] 3) Turn on the stearic acid pump 2, and adjust the opening and closing of the valve in front of the nozzle 3, so that the stearic acid ejection trajectory is basically perpendicular to the tangent line of the contact cylinder surface. The stearic acid solidifies on the su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com