Precise nozzle and processing technology thereof

A spray head, precision technology, applied in the direction of spraying device, spraying device, etc., can solve the problems of low precision, increased use cost, difficult processing, etc., to increase wear resistance and corrosion resistance, facilitate assembly and disassembly, and process The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

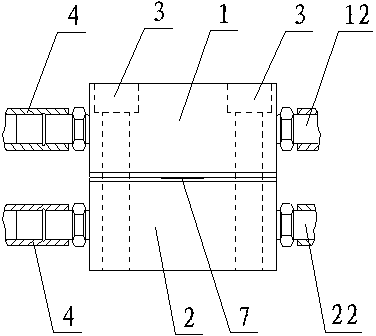

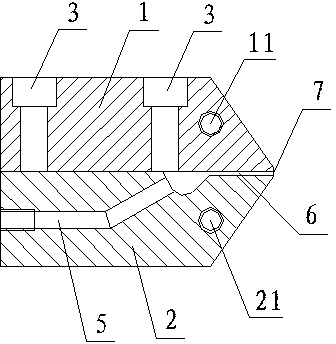

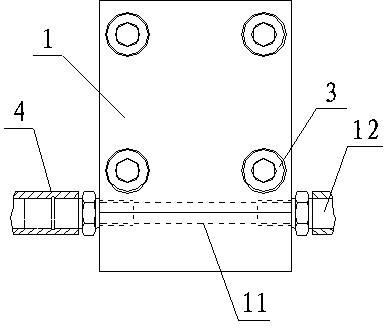

[0040] See figure 1 and figure 2 , figure 1 is the front view of the precision nozzle, figure 2 is a sectional view. In this embodiment, the shower head body includes an upper piece 1 and a lower piece 2 , which are fixed through bolts 3 , assuming that the heat source enters from the upper piece 1 and exits from the lower piece 2 .

[0041] A heat source passage 11 is provided on the side of the top sheet 1 close to the nozzle 7, and the heat source passage 11 runs through the top sheet 1 horizontally. A side of the lower sheet 2 near the nozzle 7 is provided with a lower sheet heat source channel 21 , the lower sheet heat source channel 21 runs through the lower sheet 2 horizontally, and a heat source outlet 22 is located at one end of the lower sheet heat source channel 21 . The other end of the heat source channel 11 of the upper piece and the other end of the heat source channel 21 of the lower piece are connected through a connecting pipe 4, and the connecting pipe...

Embodiment 2

[0046] The processing technology of the precision nozzle described in embodiment 1, comprises the following steps:

[0047] (1) Hot die forging after cutting the corrosion-resistant steel;

[0048] (2) The shape of the upper piece 1 and the lower piece 2 of the nozzle body is roughly machined by wire cutting technology;

[0049] (3) Drill and tap the upper piece 1 and the lower piece 2 and cut the buffer groove 6. The buffer groove 6 has a width of 6-12mm and a thickness of 0.002-0.010mm;

[0050] (4) After checking the size, coarsely grind and finely grind the joint surface of the upper piece 1 and the lower piece 2, so that the precision of the joint surface of the upper piece 1 and the lower piece 2 reaches 14 grades;

[0051] (5) Fix the upper piece 1 and the lower piece 2 with bolts 3, and correct the shape and position tolerance;

[0052] (6) Disassemble the upper piece 1 and the lower piece 2, vacuum titanium plating on the joint surface, chrome plating on the outer s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com