A deburring device for shaft parts

A technology for removing burrs and parts, which is applied in grinding/polishing safety devices, machine tools suitable for grinding the edge of workpieces, grinding machines, etc., which can solve the problem that cleanliness requirements cannot meet standards, affect the service life of shock absorbers, and burrs cannot be effective Deburring and other problems, to achieve the effect of improving burr removal efficiency, reducing work intensity and realizing automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

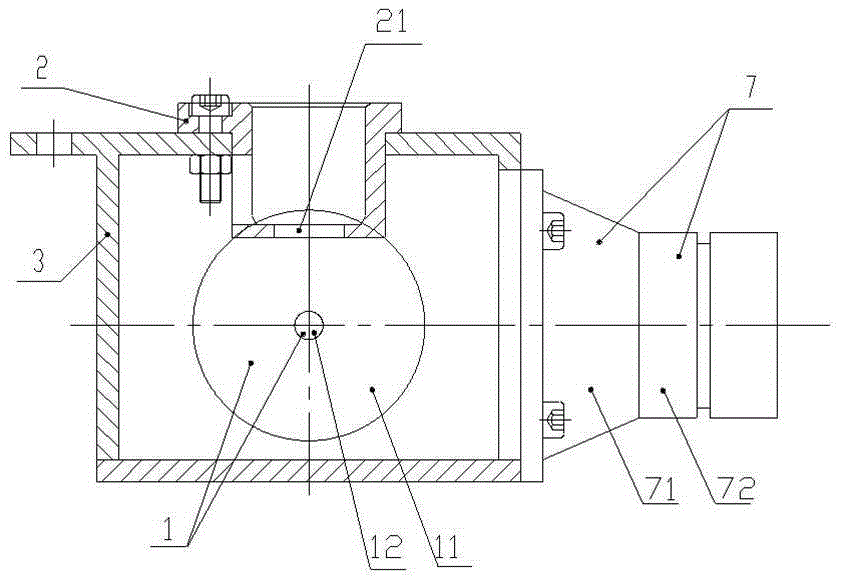

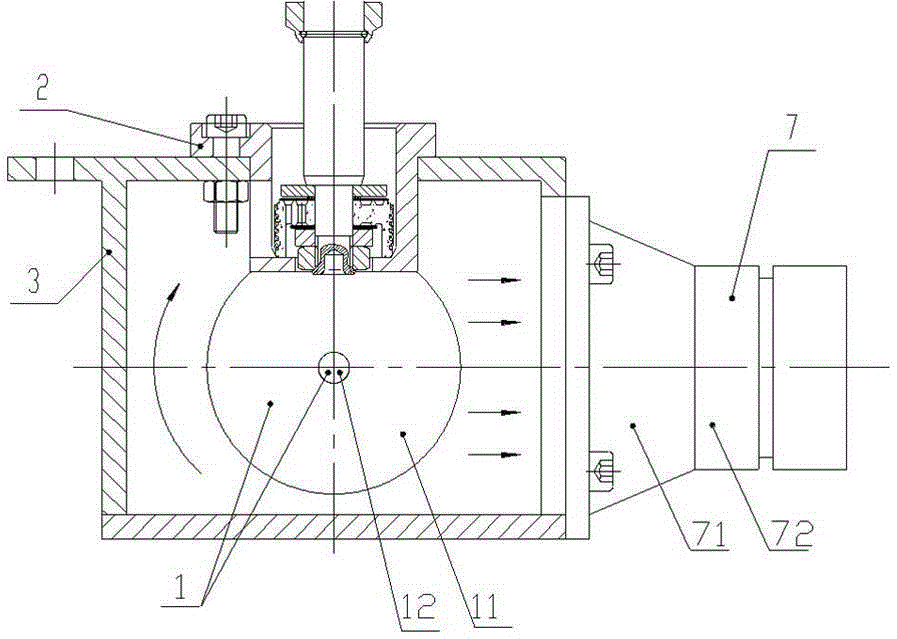

[0033] This embodiment is on the basis of embodiment 1, as Figure 4 and as Figure 5 As shown, the above-mentioned fixed base 2 includes a mounting cylinder 23 for mounting parts and a mounting plate 22 for fixing the mounting cylinder 23, wherein the mounting plate 22 is connected to the outer wall of the mounting cylinder 23 and fixed on the top of the box body 3, which is preferably The mounting cylinder 23 is molded integrally. In practice, it can also be two separate bodies connected together by means of welding or fasteners; the first through hole 21 is set at the bottom of the mounting cylinder 22 .

[0034] The above-mentioned dust suction device interface 7 is arranged on one side of the box body 3, and the dust suction device interface 7 is composed of a hollow conical cylinder 71 and a cylinder 72, and the end of the conical cylinder 71 with a smaller diameter is connected to the cylinder 72 The end with a larger diameter is fixed on the box body 3 through a lock ...

Embodiment 3

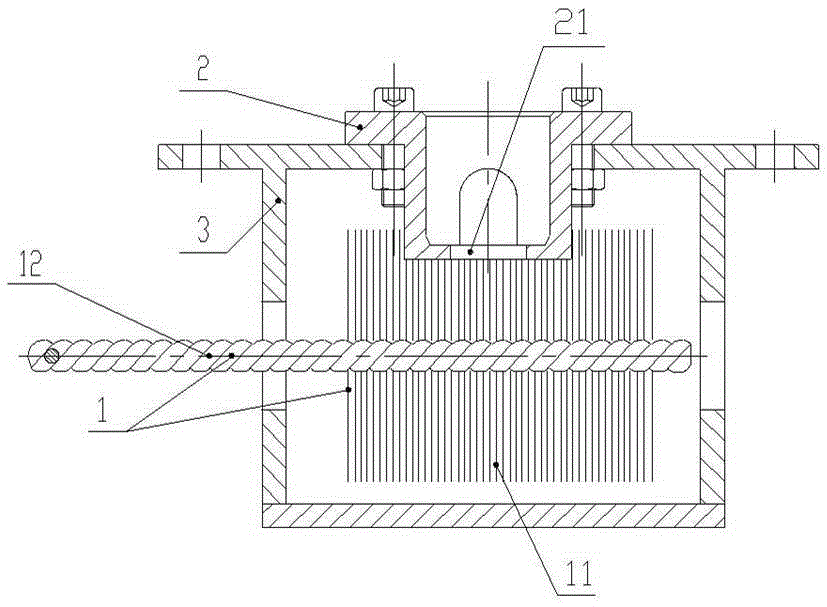

[0037] On the basis of Embodiment 1 or Embodiment 2, the brush head of the above-mentioned wire brush 1 includes bristles 11 and the front end of a brush handle 12 connected to the bristles 11, the above-mentioned bristles 11 are wavy stainless steel wires with a diameter less than 0.5mm, and the above-mentioned brush handle 12 is a spiral iron wire, which is formed by spirally winding an iron wire with a diameter of 2mm to 4mm. In practical applications, the diameter of the bristles 11 and the diameter of the handle 12 can be adjusted according to specific needs.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com