Perforating charge assembly manipulator

A technology of perforating bullets and manipulators, which is applied in the field of manipulators to achieve the effects of easy loading and unloading, easy control, and convenient maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention is described in more detail below in conjunction with accompanying drawing example:

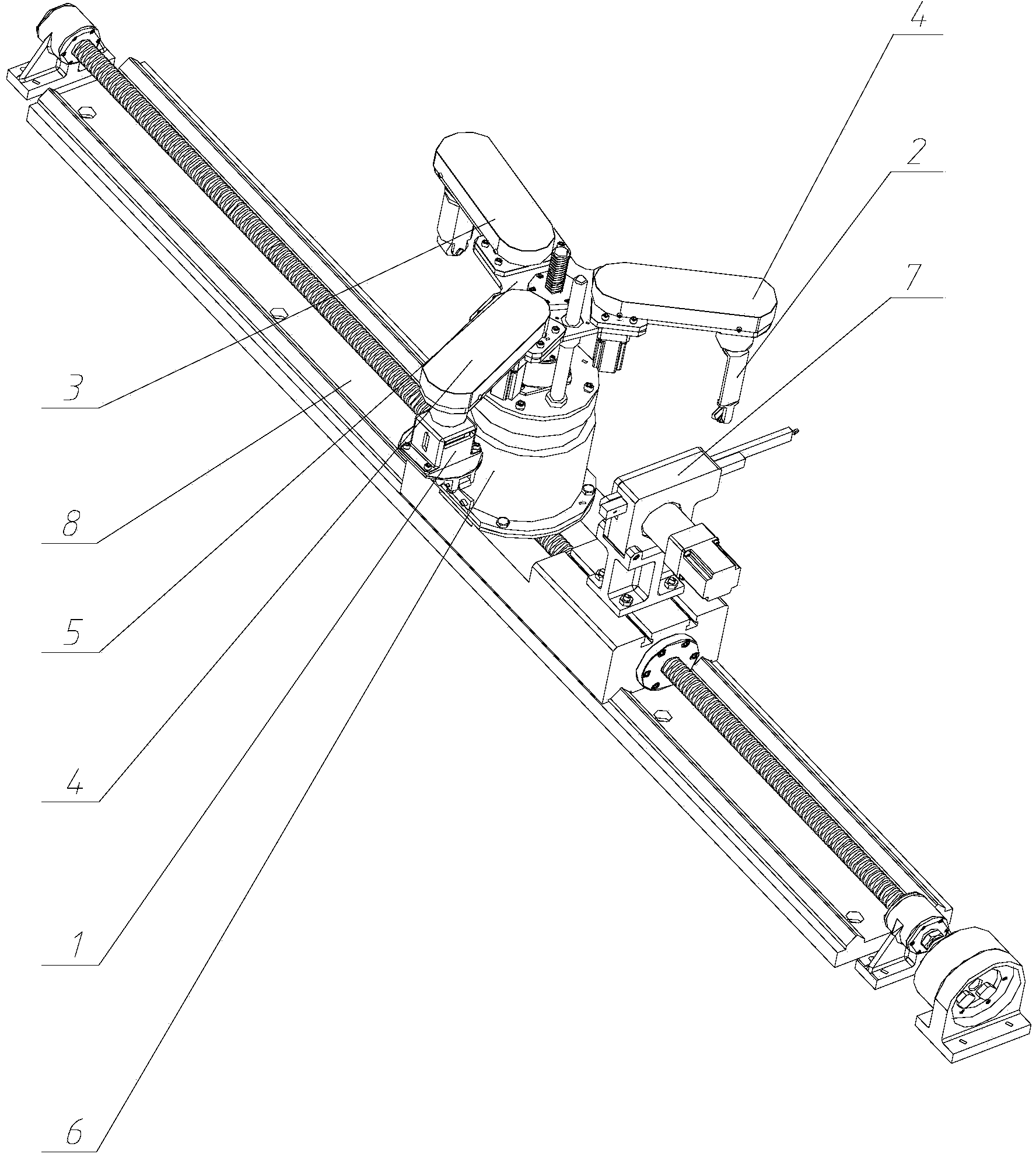

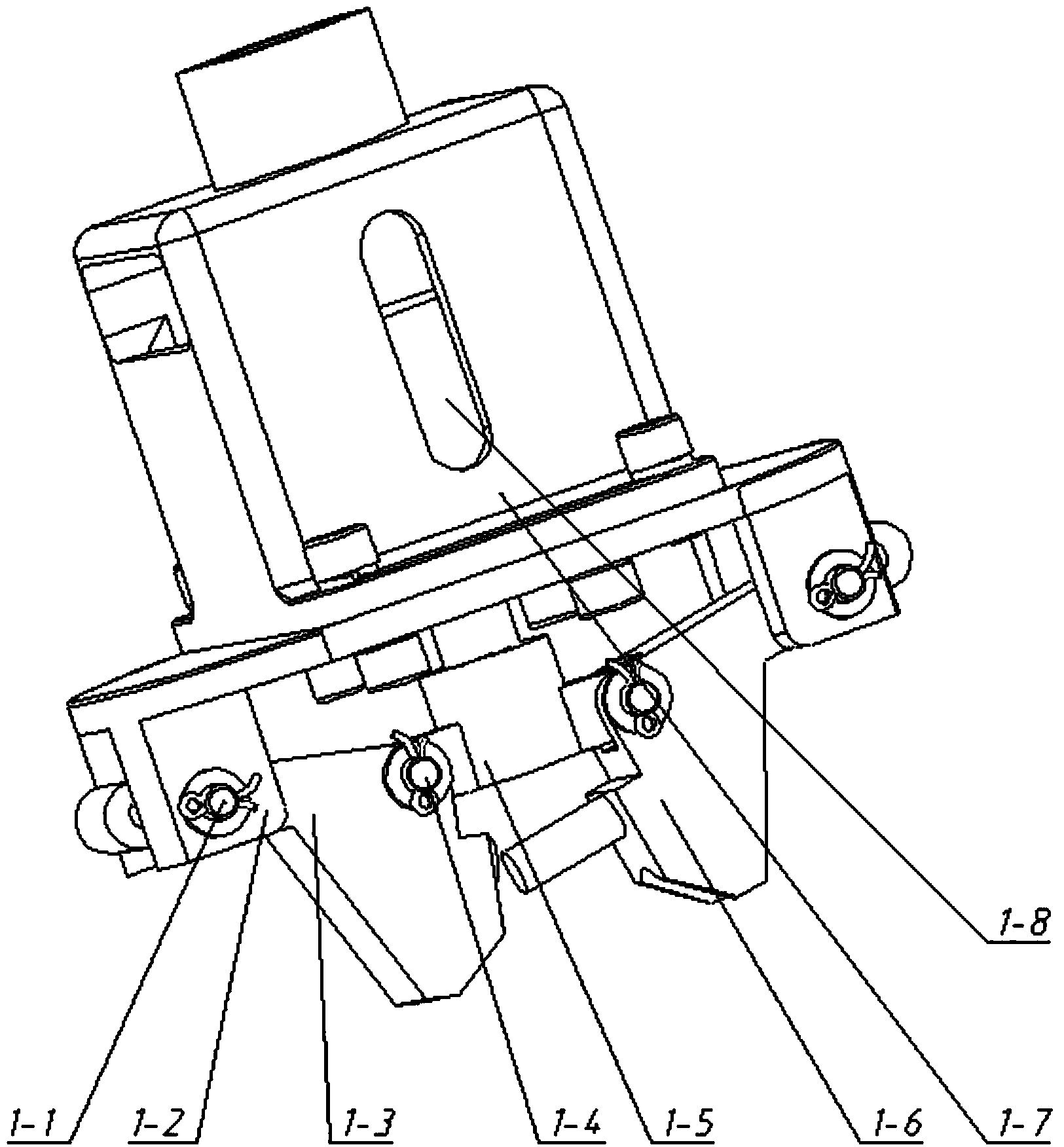

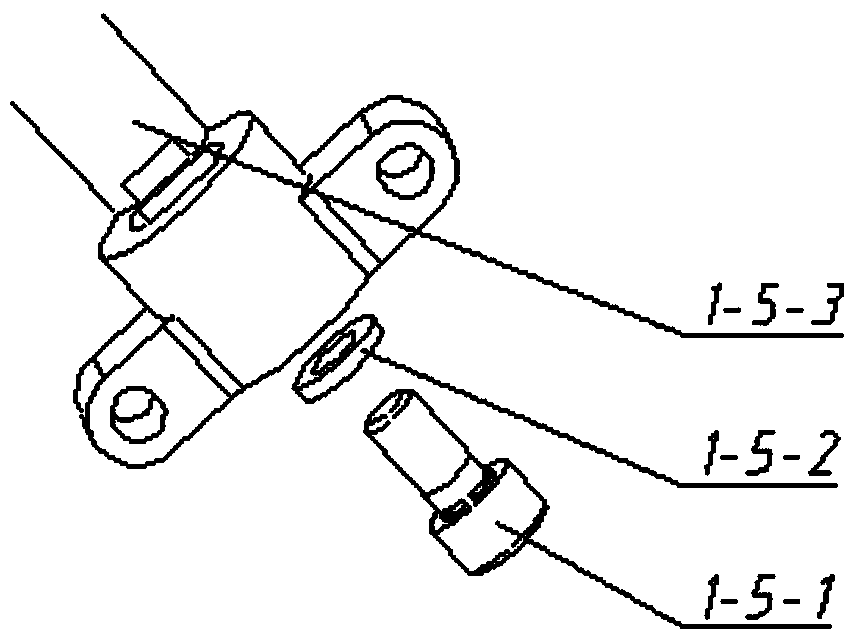

[0032] combine figure 1 ~9, the perforating charge assembly manipulator of the present invention is mainly composed of a perforating charge assembly gripper 1, a synergistic powder assembly gripper 2, a pressing device 3, an arm and a wrist 4, a lifting mechanism 5, and a fuselage rotation mechanism 6 , Winding device 7, slide mechanism 8 are formed. Perforating charge assembly gripper 1 consists of support pin 1-1, mounting plate 1-2, finger A1-3, connecting pin 1-4, connecting head 1-5, finger B1-6, connecting box 1-7 , double-acting thin cylinder 1-8, the joint head 1-5 includes hexagon socket head screw 1-5-1, flat washer 1-5-2, cylinder piston rod 1-5-3; synergistic gunpowder assembly claw 2 is composed of The following parts are composed of: connecting arm A2-1, connecting arm B2-2, vacuum suction cup 2-3; pressing device 3 is composed of connecting pin 3-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com