Production method and device of spiral PVC (Polyvinyl Chloride) muffler tube

A production method and technology of PVC pipes, applied in the production field of PVC spiral silencer pipes, can solve the problems of defective products and waste products, and achieve the effect of ensuring the rate of finished products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

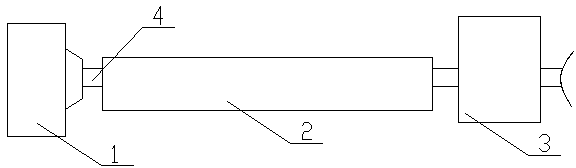

[0012] Embodiment 1: The present invention is by adjusting the position of the screw machine, it is arranged behind the vacuum water cooling box 2, and the rotary machine and the tractor are combined to form the rotary tractor 3, although adopting this method will produce some parts when starting production. Waste pipe, but when the solidified pipe fitting 4 is in contact with the rotary tractor 3, with the transmission of torque, the twist of the pipe fitting will be generated from the deformable area and gradually transmitted to the extrusion head 1, so that the ribbed strip The high-quality PVC pipe is twisted and spiraled, and the twisted rib-shaped strips can be well shaped during the gradual cooling process, thus ensuring the yield of the spiral silencer pipe.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com