Automobile brake energy storing-releasing driving device and automobile brake energy storing-releasing driving method

A technology of automobile braking and driving devices, applied in the direction of auxiliary driving devices, power devices, control devices, etc., can solve the problems of limited efficiency, high energy loss, and many on-board equipment, so as to prolong the service life, increase the cylinder volume, The effect of reducing volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

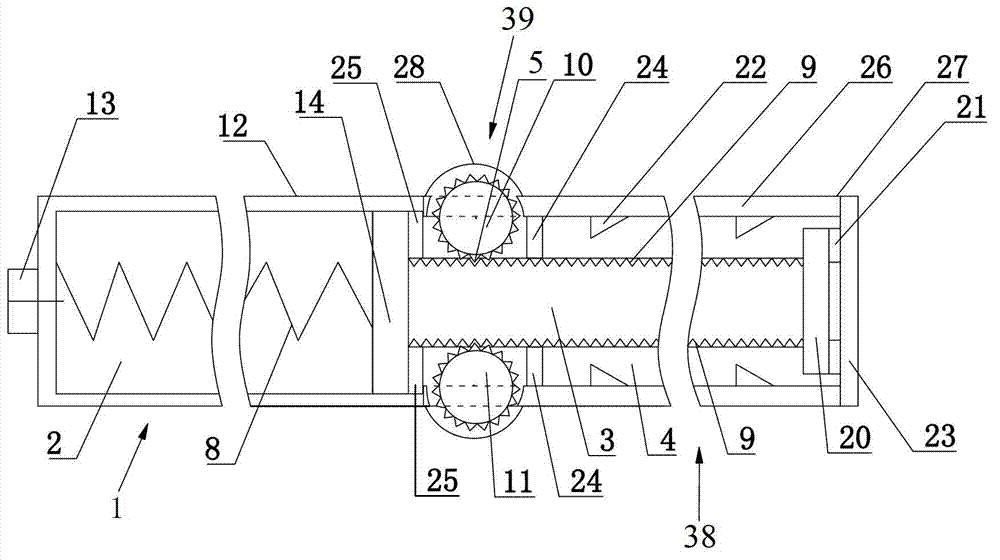

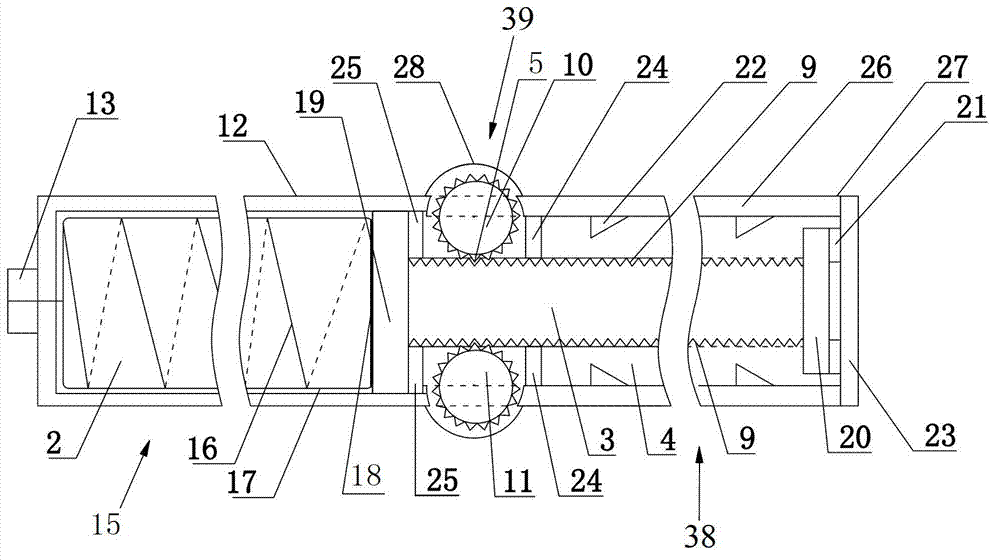

[0044] Such as figure 1 , Figure 5 and Figure 6 As shown, this embodiment describes a vehicle brake energy storage-energy release driving device 34, including:

[0045] The spring cylinder 1 includes a cylinder wall 12 forming a cylinder cavity, a piston 14 that is slidably engaged with the inside of the cylinder wall 12, and a spring that is connected between the piston 14 and the end of the spring cylinder 1 and whose direction of elasticity is parallel to the sliding direction of the piston 14. A coil spring 8, a gas medium 2 is arranged in the cylinder chamber;

[0046] The translation part 38 includes one end connected to the piston 14, a double-sided tooth column 3 with rack slots 9 respectively distributed on opposite sides along the sliding direction, and accommodating the double-sided tooth column 3 to slide therein The translation part shell 27;

[0047] The rotating part 39 is two gears 10 and 11 that mesh and match with the rack groove 9 corresponding to the ...

Embodiment 2

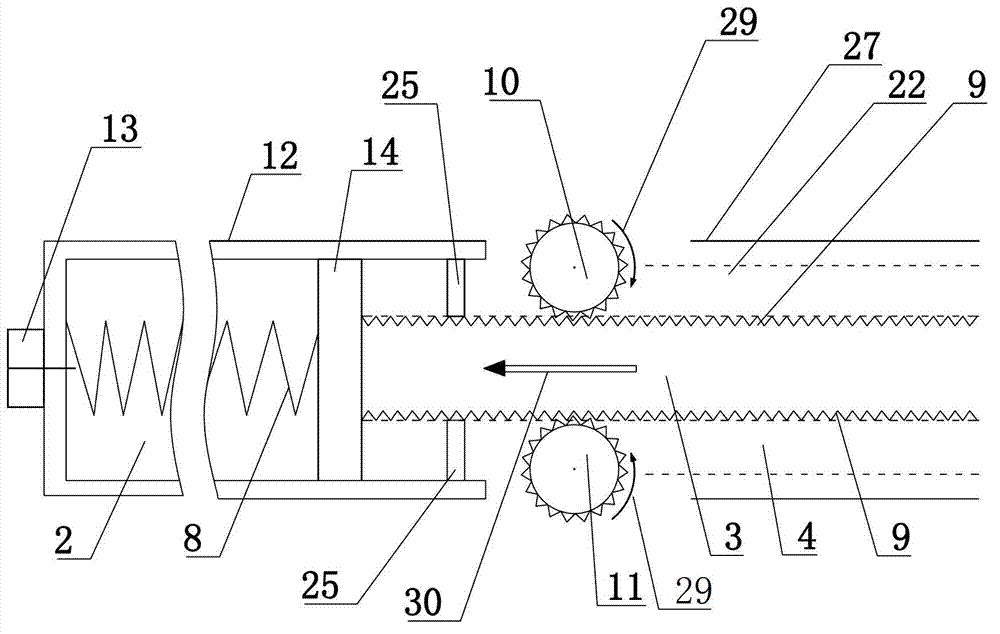

[0065] This embodiment records a vehicle brake energy storage-energy release driving method of the above-mentioned device, including the following steps:

[0066] When the car brakes and decelerates, the car transmission shaft-wheel rotation causes the two gears of the car brake energy storage-energy release driving device to rotate in the first rotation direction 29 through the input transmission system, and the two gears and the double-sided gear column of the translation part The meshing makes the double-sided tooth column of the translation part drive the piston 14, 19 to translate 30 in the first direction, compress the gas medium 2 of the spring cylinder 1, 15 and the coil spring 8, 16, so that the device stores energy, and at the same time, the automobile system Slow down;

[0067] When the car starts to accelerate, the compressed gas medium 2 in the spring cylinders 1, 15 and the coil springs 8, 16 release energy and expand, so that the pistons 14, 19 drive the double-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com