A single-drive material moving mechanism

A single-drive, sliding zone technology, applied in the direction of conveyor objects, transportation and packaging, etc., can solve the problems that affect the overall speed of the equipment, cannot adapt to the development trend, lead wires move into the blanking part, etc., to shorten the action response time and reduce the handling Process, the effect of increasing the speed of movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention is described below in conjunction with accompanying drawing and specific embodiment:

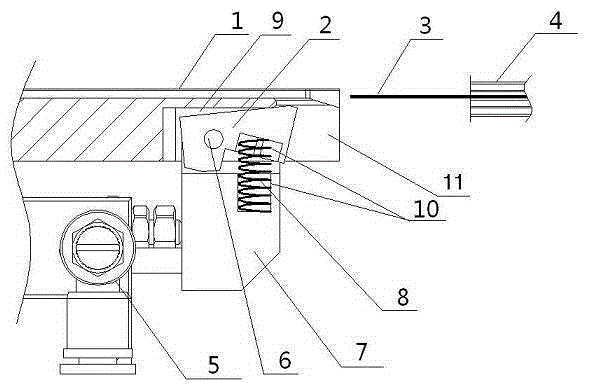

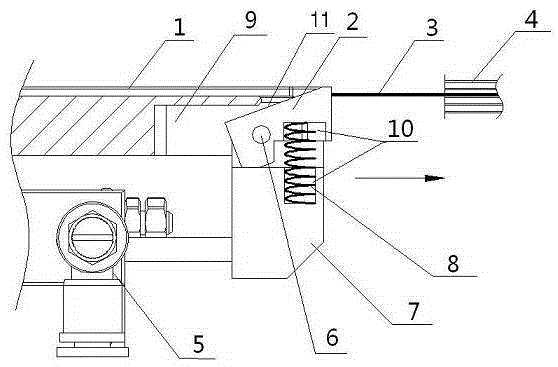

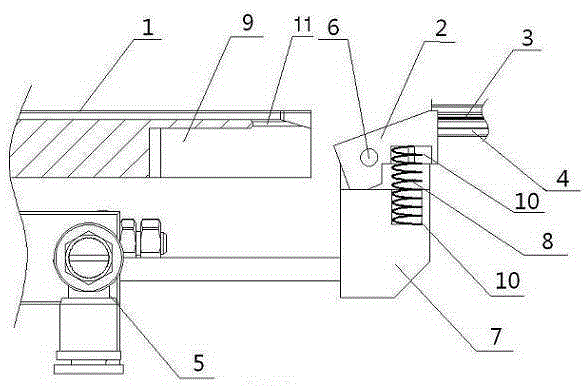

[0013] figure 1 It is a schematic diagram of the present invention when the cylinder piston rod is in a contracted state. A single-drive material shifting mechanism, including a lead track 1 for the lead wire 3 to move, a material box 4 for the lead wire 3 to move in, and a track gap 9 that is open below and behind the lead track 1 and located in the track gap. In the free sliding area 11 at the rear, a pushing block 2 is provided in the track gap 9, and the pushing block 2 is slidably connected in the track gap 9 and the free sliding area 11; the initial position of the pushing block 2 of the present invention is just in this track gap 9 in. One side of push block 2 is connected with push block fixed block 7 by pin 6 rotation, and the other side of push block 2 is connected with push block fixed block 7 by stage clip 8; More specifically, between push block 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com