Method for producing organic fertilizer by using pig manures

A technology of organic fertilizer and pig manure, which is applied in the preparation of organic fertilizer, organic fertilizer, and the treatment of biological organic parts, etc., can solve the problems of poor efficacy of organic fertilizer and high nutrient content of organic fertilizer, and achieve the reduction of nutrient loss and product quality. High, improve the effect of fermentation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

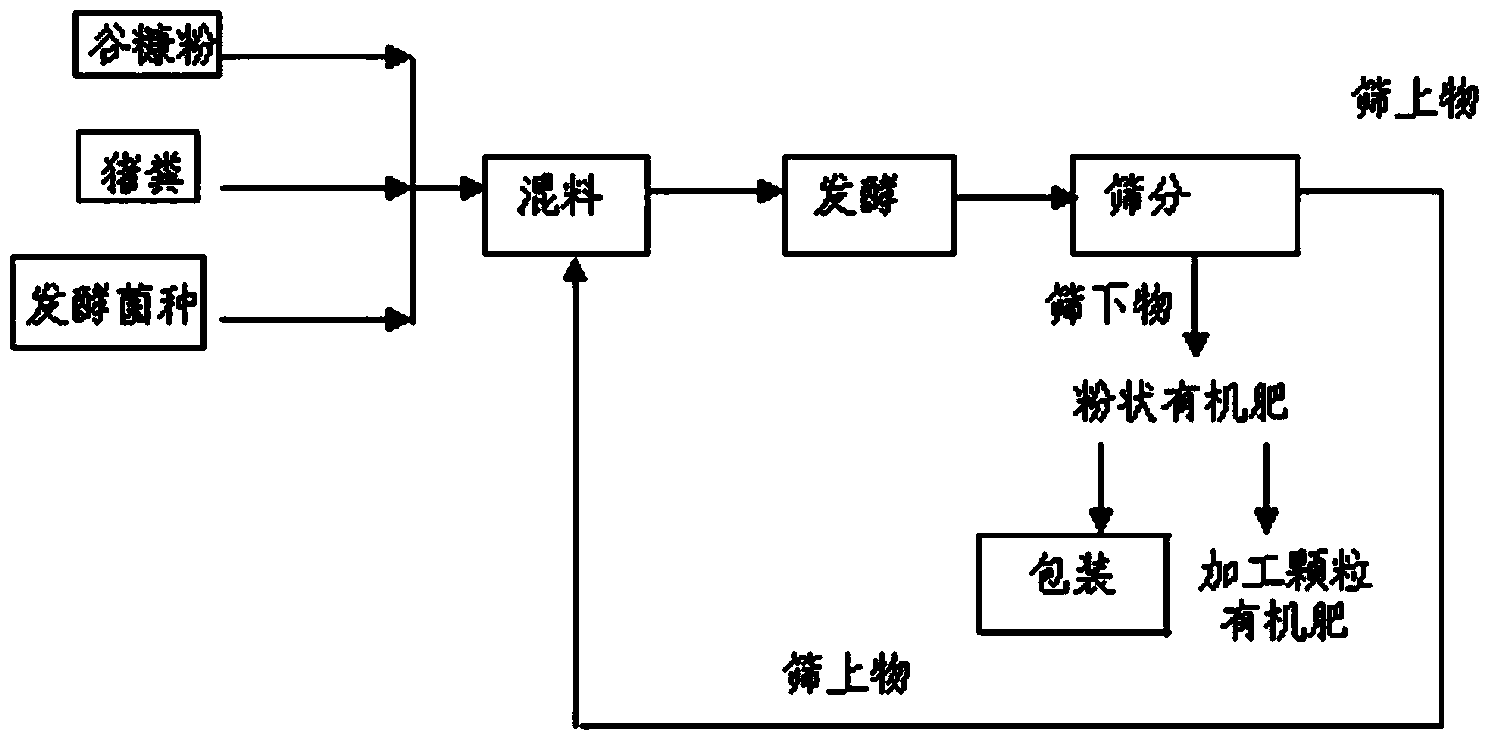

[0036] Such as figure 1 Shown, a kind of method utilizing pig manure to produce organic fertilizer comprises the steps:

[0037] (1) Mixing: Mix pig manure with a water content of 70% and rice bran, the ratio is 900kg by weight of pig manure, 100kg by weight of rice bran, add 0.18kg of EM mixed bacteria agent, and then add plant ash to mix and adjust evenly Water content, so that the water content of the mixed material is 50%.

[0038](2) Primary fermentation: Transport the mixed material obtained in step (1) to the fermentation workshop with a forklift and pile it up in stacks. The width of each stack is 1.8m and the height is 1.2m. Carry out aerobic fermentation. , the fermentation time is 15 days, and the pile is turned every 2 days with a turning machine, and the natural oxygenation is used during the turning process. The moisture content of the material after one fermentation is about 45%. Aerobic fermentation is the use of external enzymes of aerobic microorganisms to...

Embodiment 2

[0043] Such as figure 1 Shown, a kind of method utilizing pig manure to produce organic fertilizer is characterized in that comprising the steps:

[0044] (1) Mixing: Mix pig manure with a water content of 80% and rice bran. The ratio is 1100kg by weight of pig manure and 130kg by weight of rice bran. Add 0.22kg of EM mixed bacteria agent, and then add plant ash to mix and adjust evenly Moisture content, so that the water content of the mixed material is 60%;

[0045] (2) Primary fermentation: Transport the mixed material obtained in step (1) to the fermentation workshop with a forklift and stack it into stacks. The width of each stack is 1.8m and the height is 1.6m. The time is 17 days, and the pile is turned once every 2 days with a turner;

[0046] (3) Secondary fermentation: Pile the products obtained in step (2) into piles for anaerobic fermentation, and the fermentation time is 7 days;

[0047] (4) Moisture adjustment: add the product obtained in step (3) to plant ash...

Embodiment 3

[0050] Such as figure 1 Shown, a kind of method utilizing pig manure to produce organic fertilizer comprises the steps:

[0051] (1) Mixing: Mix pig manure with a water content of 75% and rice bran. The ratio is 1000kg by weight of pig manure and 150kg by weight of rice bran. Add 0.2kg of EM mixed bacteria agent, and then add plant ash to mix evenly. Moisture content, so that the water content of the mixed material is 55%.

[0052] (2) Primary fermentation: Transport the mixed material obtained in step (1) to the fermentation workshop with a forklift and pile it up in stacks. The width of each stack is 1.8m and the height is 1.4m. Carry out aerobic fermentation and ferment in summer , the fermentation time is 20 days, and the pile is turned every 2 days with a turning machine.

[0053] (3) Secondary fermentation: the products obtained in step (2) are piled up with a forklift for anaerobic fermentation, and the fermentation time is 9 days.

[0054] (4) Moisture adjustment: T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com