Soft PU foamed plastic and preparation method thereof

A foam plastic, soft technology, applied in the field of foam materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

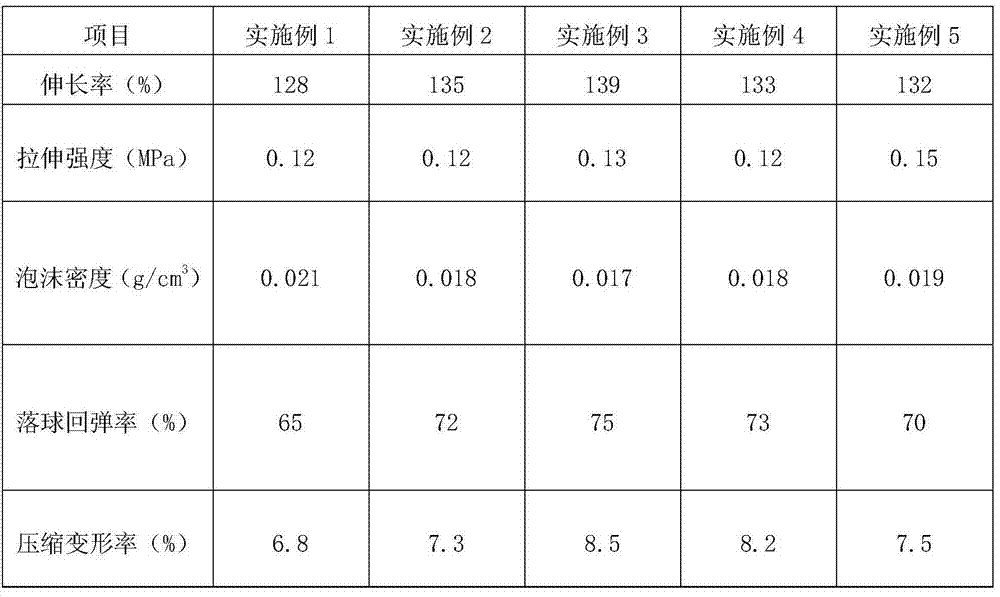

Examples

Embodiment 1

[0012] A kind of flexible PU foam plastics, comprising by weight components: 80 parts of PU, 70 parts of trihydroxy polyether, 20 parts of isocyanate, 1 part of emulsified silicone oil, 0.2 part of tertiary amine, 15 parts of toluene diisocyanate, and 1 part of foam stabilizer , 3 parts of foaming agent TCEP, 3 parts of water.

[0013] Above-mentioned soft PU foamed plastics is prepared according to the following steps:

[0014] (1) Weigh each component according to parts by weight;

[0015] (2) Stir and mix PU, trihydroxypolyether, toluene diisocyanate, isocyanate and emulsified silicone oil in a mixer, add tertiary amine, foam stabilizer, foaming agent TCEP and water after mixing and foam through the foaming machine , The foaming temperature is 25°C.

Embodiment 2

[0017] A kind of flexible PU foam plastics, comprising by weight components: 86 parts of PU, 73 parts of trihydroxypolyether, 25 parts of isocyanate, 2 parts of emulsified silicone oil, 0.3 part of tertiary amine, 18 parts of toluene diisocyanate, and 2 parts of foam stabilizer , 4 parts of foaming agent TCEP, 4 parts of water.

[0018] Above-mentioned soft PU foamed plastics is prepared according to the following steps:

[0019] (1) Weigh each component according to parts by weight;

[0020] (2) Stir and mix PU, trihydroxypolyether, toluene diisocyanate, isocyanate and emulsified silicone oil in a mixer, add tertiary amine, foam stabilizer, foaming agent TCEP and water after mixing and foam through the foaming machine , The foaming temperature is 28°C.

Embodiment 3

[0022] A kind of flexible PU foam plastics, comprising by weight components: 89 parts of PU, 75 parts of trihydroxy polyether, 26 parts of isocyanate, 3 parts of emulsified silicone oil, 0.4 part of tertiary amine, 20 parts of toluene diisocyanate, and 3 parts of foam stabilizer , 5 parts of foaming agent TCEP, 5 parts of water.

[0023] Above-mentioned soft PU foamed plastics is prepared according to the following steps:

[0024] (1) Weigh each component according to parts by weight;

[0025] (2) Stir and mix PU, trihydroxypolyether, toluene diisocyanate, isocyanate and emulsified silicone oil in a mixer, add tertiary amine, foam stabilizer, foaming agent TCEP and water after mixing and foam through the foaming machine , The foaming temperature is 35°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Foam density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com