Programmed heating type melt polymerization method for polybenzimidazole

A polybenzimidazole and temperature-programmed technology, applied in the field of polymer materials, can solve the problems of poor controllability of polybenzimidazole reaction degree and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

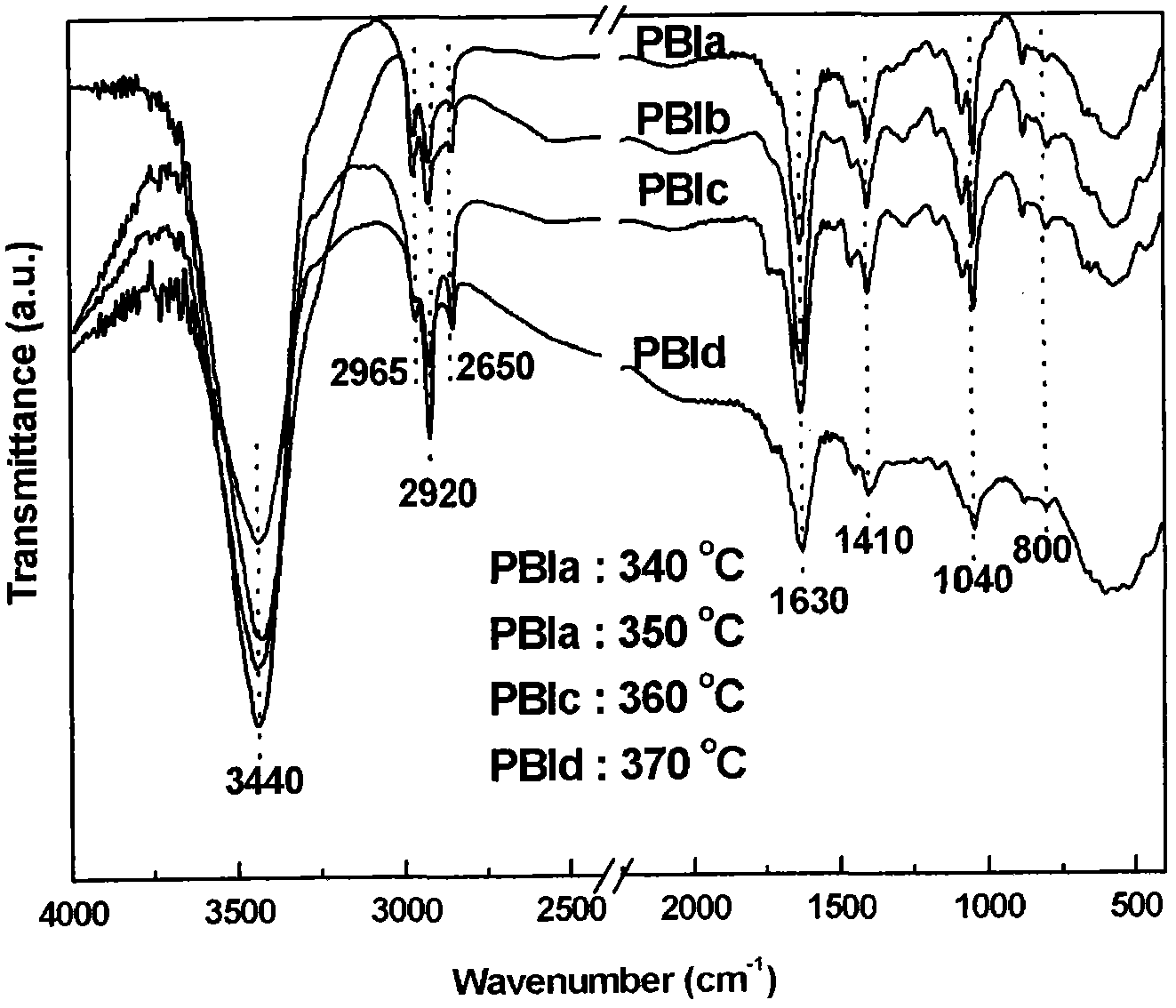

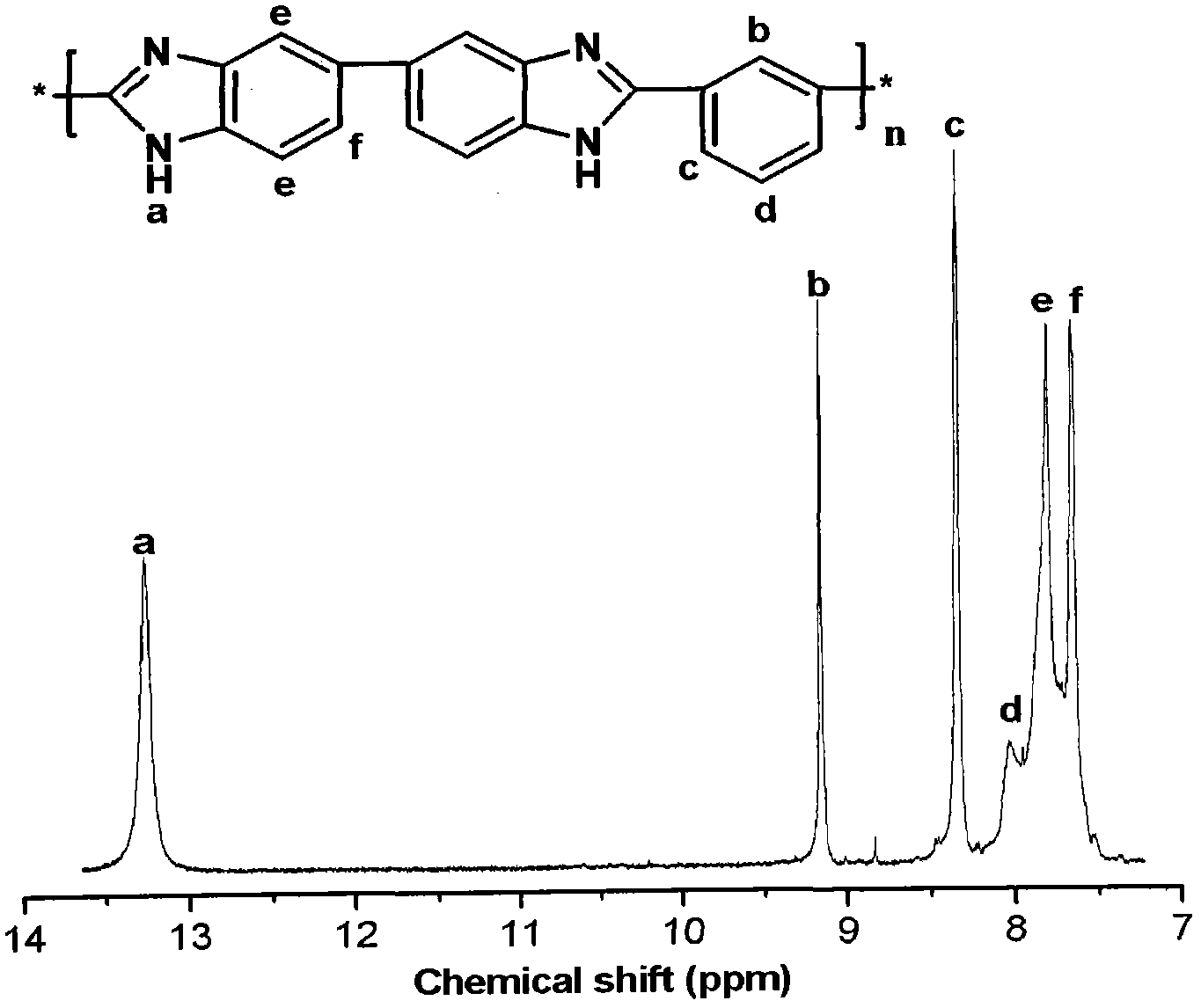

Embodiment 1

[0023] The first step: the reaction monomer 3,3'-diaminobenzidine (DAB) 0.01-0.2mol (preferably 0.02mol) and diphenyl isophthalate (DPIP) 0.01-0.2mol ( Preferably 0.02mol) was added into a 1000mL three-neck flask equipped with a stirrer, nitrogen inlet and outlet, and the reaction flask was placed in an oil bath. The oil bath is heated and controlled at 160-180°C (preferably 180°C). Stir mechanically for 1-2h (preferably 2h) to melt the reaction mixture completely, and stop stirring when it is difficult to stir. Then the reaction mixture will slowly expand to a full bottle, and the reaction temperature will be maintained at 270-275°C (preferably 270°C) for 1-3h (preferably 3h), until no more phenol is discharged from the tail gas port, and the heating will be stopped. After cooling down to room temperature, the feeding of nitrogen gas was stopped, and the reaction mixture was taken out and ground to obtain a powdery prepolymer.

[0024] Step 2: Add the prepolymer powder into...

Embodiment 2

[0027] As described in the first step of Example 1, a powdery prepolymer was obtained.

[0028]Step 2: Add the prepolymer powder into a three-necked flask with a stirrer, nitrogen inlet and outlet, and heat it with an oil bath. Directly heated to 350°C for 3 hours, and after cooling down, the PBIb polymer can be obtained. The polymer was washed with absolute ethanol to remove residual phenol, and dried in a vacuum oven at 150°C for 24h.

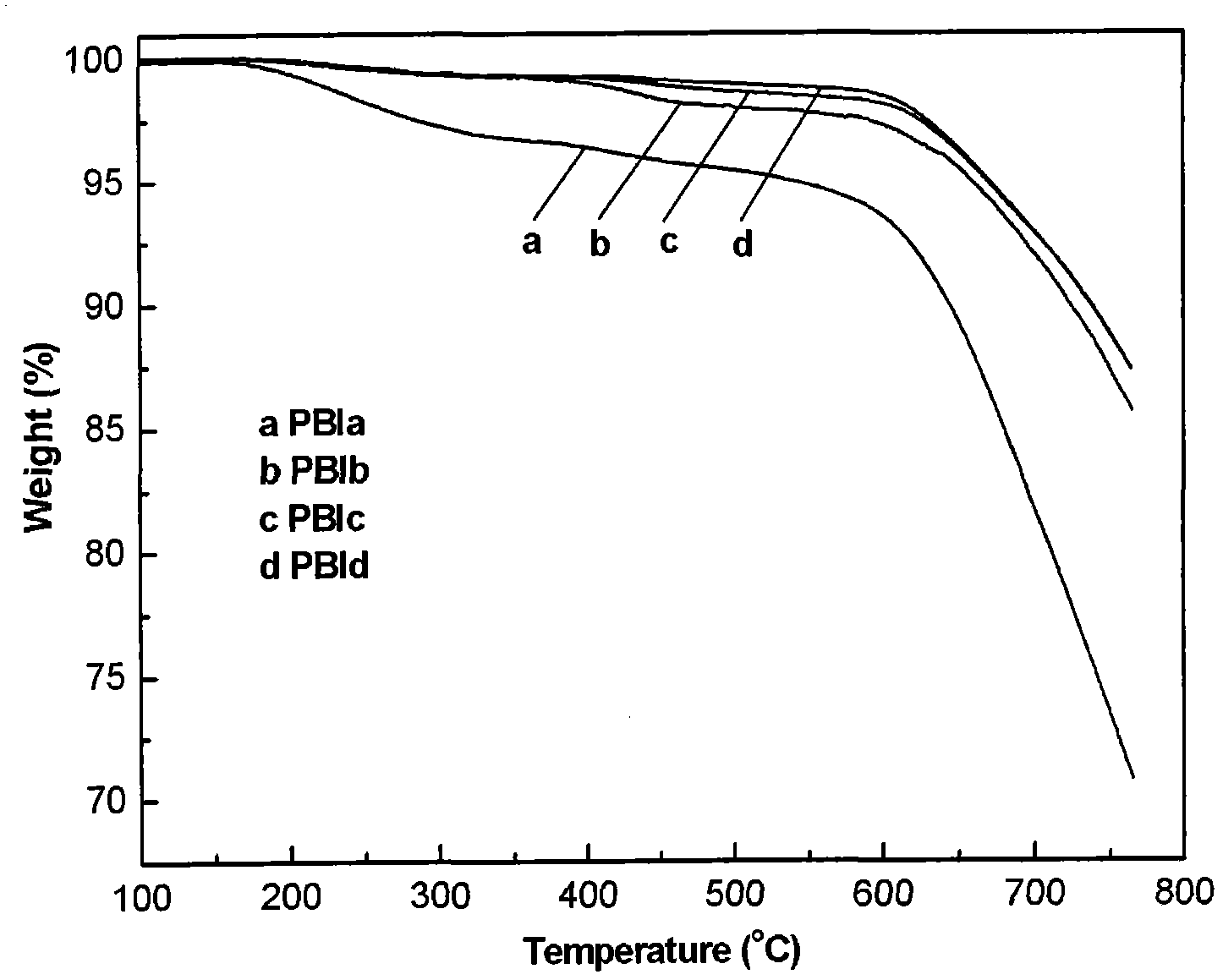

[0029] The logarithmic reduced viscosity of the PBIb measured by the method described in Example 1 is 0.6675g.dl -1 , the thermal stability has been significantly improved, T d5% and T d10% They are 660°C and 715°C, respectively.

Embodiment 3

[0031] As described in the first step of Example 1, a powdery prepolymer was obtained.

[0032] In the second step, the prepolymer powder is added to a three-neck flask with a stirrer, nitrogen inlet and outlet, and the oil bath is still used for heating. Directly heat to 350°C for 3 hours, and after cooling down, the PBI polymer can be obtained. The polymer was washed with absolute ethanol to remove residual phenol, and dried in a vacuum oven at 150°C for 24h.

[0033] The logarithmic reduced viscosity of the PBIc measured by the method described in Example 1 is 0.7774g.dl -1 , the thermal stability has been significantly improved, T d5% and T d10% They are 670°C and 736°C, respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com