Flame-retardant aerosol paint for mine marking

An aerosol paint and flame-retardant technology, which is applied in coatings, fire-resistant coatings, polyester coatings, etc., can solve the problems of inconvenient use of brushing coatings, achieve good social and economic benefits, and have obvious effects and ease of use. convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

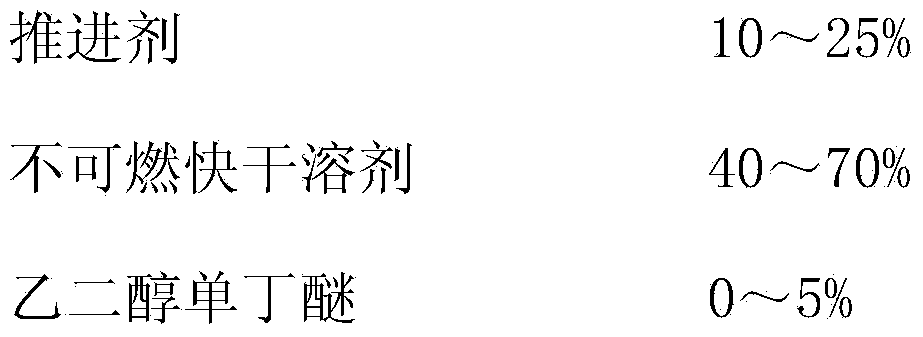

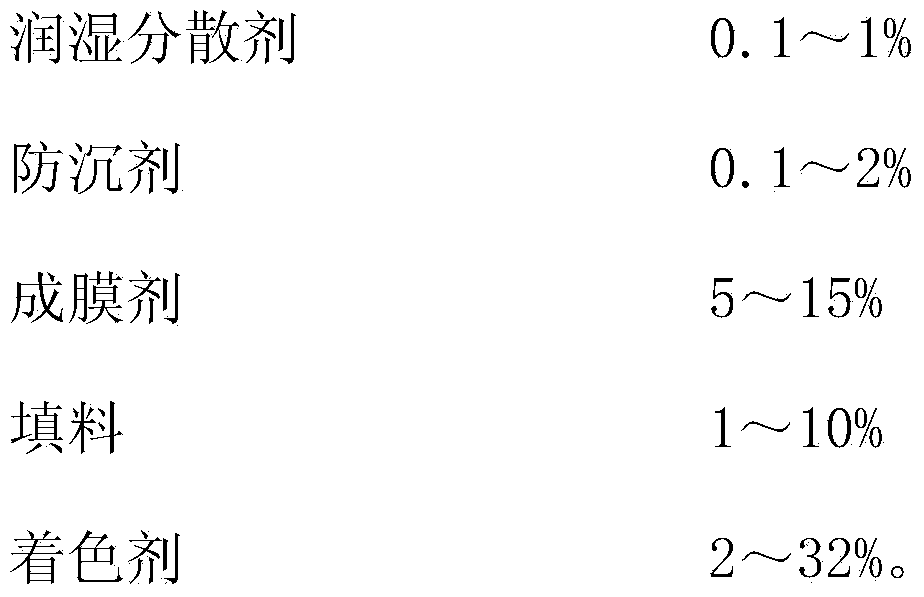

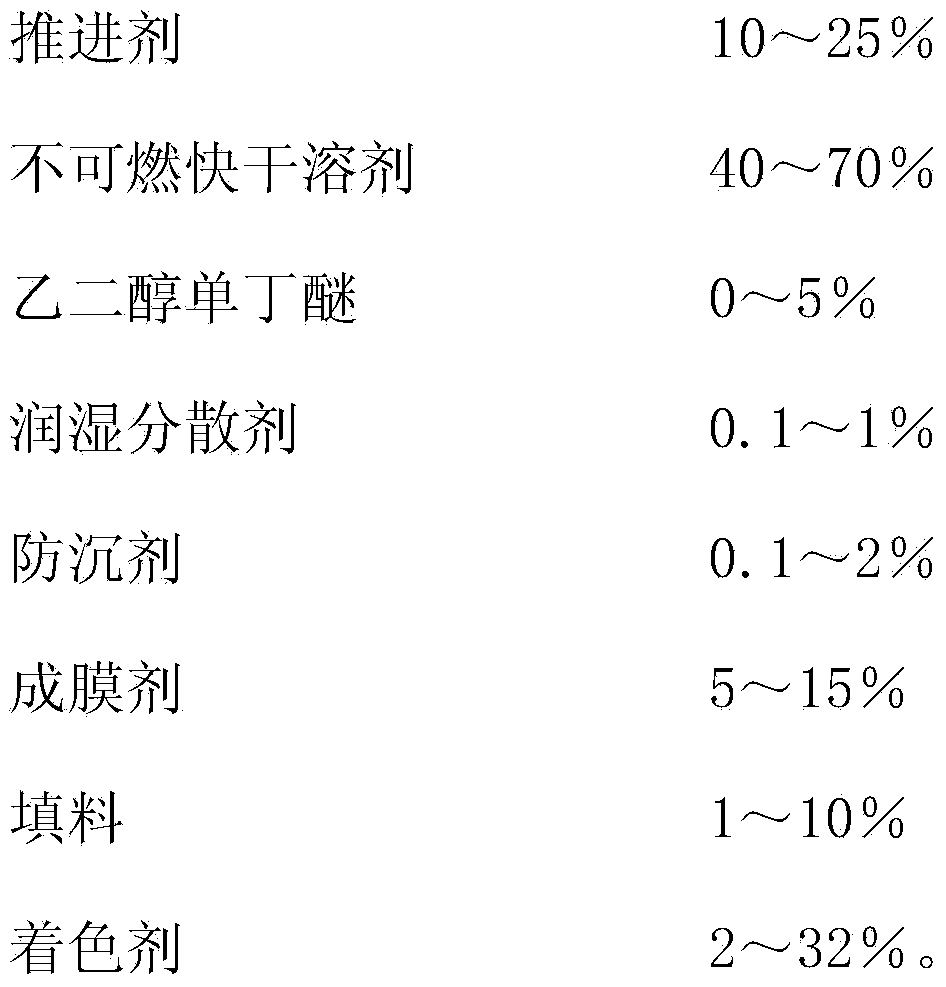

Method used

Image

Examples

Embodiment 1

[0025] Weighing agent liquid component raw materials nonafluorobutyl methyl ether 43.27%, ethylene glycol monobutyl ether 1.54%, ANTI-TERRA 0.79%, fumed silica 2.9%, acrylic resin 10%, calcium carbonate 8%, fluorescent orange pigment 20%;

[0026] The propellant is 12% tetrafluoroethane and 1.5% carbon dioxide;

[0027] The preparation method of embodiment 1 is:

[0028] Dissolve and disperse ethylene glycol monobutyl ether, wetting and dispersing agent, anti-sedimentation agent, film-forming agent, filler and colorant in a non-flammable and fast-drying solvent, and then grind it through a sand mill until the particle size of the filler and colorant is 15 μm, then filter, check the color, and check the qualified agent solution, and finally pour the agent solution into the aerosol can, install the valve, seal the seal, fill the propellant, take a water bath, install the nozzle, and install the outer cover. Example 2:

Embodiment 2

[0029] Weigh 45.21% of dichloromethane, 2% of ANTI-TERRA, 2% of organic bentonite, 7% of acrylic resin, 5% of calcium carbonate, and 10% of titanium dioxide;

[0030] The propellant is 30% tetrafluoroethane;

[0031] The preparation method of Example 2 is the same as that of Example 1, and the particle diameters of fillers and colorants in Example 2 are 18 μm.

Embodiment 3

[0033] Weigh the raw materials of the liquid components: pentafluorobutane 50%, ethylene glycol monobutyl ether 3%, ANTI-TERRA 0.79%, kaolin 2%, alkyd resin 7.21%, calcium carbonate 10%, blue pigment 15% ;

[0034] The propellant is 10% tetrafluoropropylene and 2% carbon dioxide;

[0035] The preparation method of Example 3 is the same as that of Example 1, and the particle size of fillers and colorants in Example 3 is 20 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com