Method for preparing white fluorescent quantum dot composite particles by microfluid method

A technology of fluorescent quantum dots and composite particles, which is applied in the manufacturing field of quantum dot backlight technology, can solve the problems of poor stability of quantum dot materials and low quantum efficiency, and achieve the effect of simple and feasible preparation method, stable luminous performance and uniform spectrum

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

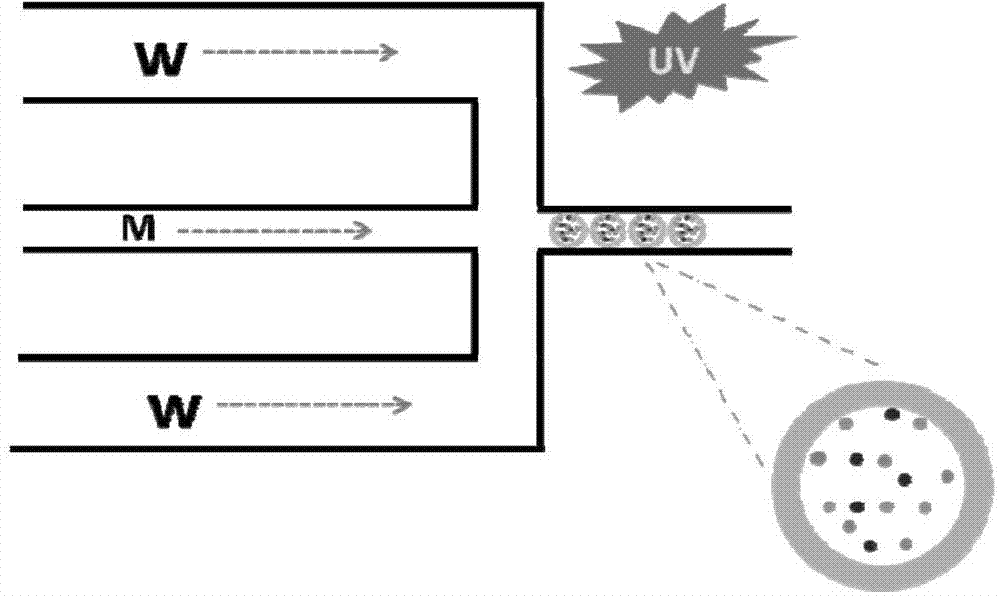

[0037] Such as figure 1 As shown, 1wt% sodium dodecylsulfonate (SDS) aqueous solution W was injected into the outer fluid channel at a flow rate of 2ml / hr. Fluid M1 is composed of 40% red, green and blue quantum dots mixed in a certain proportion (such as 1:3:15) and 60% methacryloylpropyl dimethylchlorosilane (DMS-R11), in 0.5ml A flow rate of / hr is injected into the inner channel, and the monomer is exposed to UV radiation for polymerization.

Embodiment 2

[0039] Such as figure 1As shown, a 1.5wt% sodium dodecylsulfonate (SDS) aqueous solution W was injected into the outer fluid channel at a flow rate of 2.5ml / hr. Fluid M1 is composed of 55% red, green and blue quantum dots mixed in a certain proportion and 45% pentaerythritol triacrylate (PETA-3), injected into the inner channel at a flow rate of 0.8ml / hr, and the monomer is exposed to UV radiation Polymerize below.

Embodiment 3

[0041] like figure 1 As shown, 1wt% sodium dodecylsulfonate (SDS) aqueous solution W was injected into the outer fluid channel at a flow rate of 3ml / hr. Fluid M1 is composed of 50% red, green and blue quantum dots mixed in a certain proportion and 50% pentaerythritol triacrylate (PETA-3), injected into the inner channel at a flow rate of 1.2ml / hr, and the monomer is exposed to UV radiation Polymerize below.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com