Cold-drawing and cold-rolling mixed molding method of stainless steel seamless pipe

A technology of seamless steel pipe and mixed forming, applied in the field of cold drawing and cold rolling mixed forming of stainless steel seamless steel pipe, can solve the problems of grain size not meeting the requirements, not meeting national standards, uneven wall thickness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

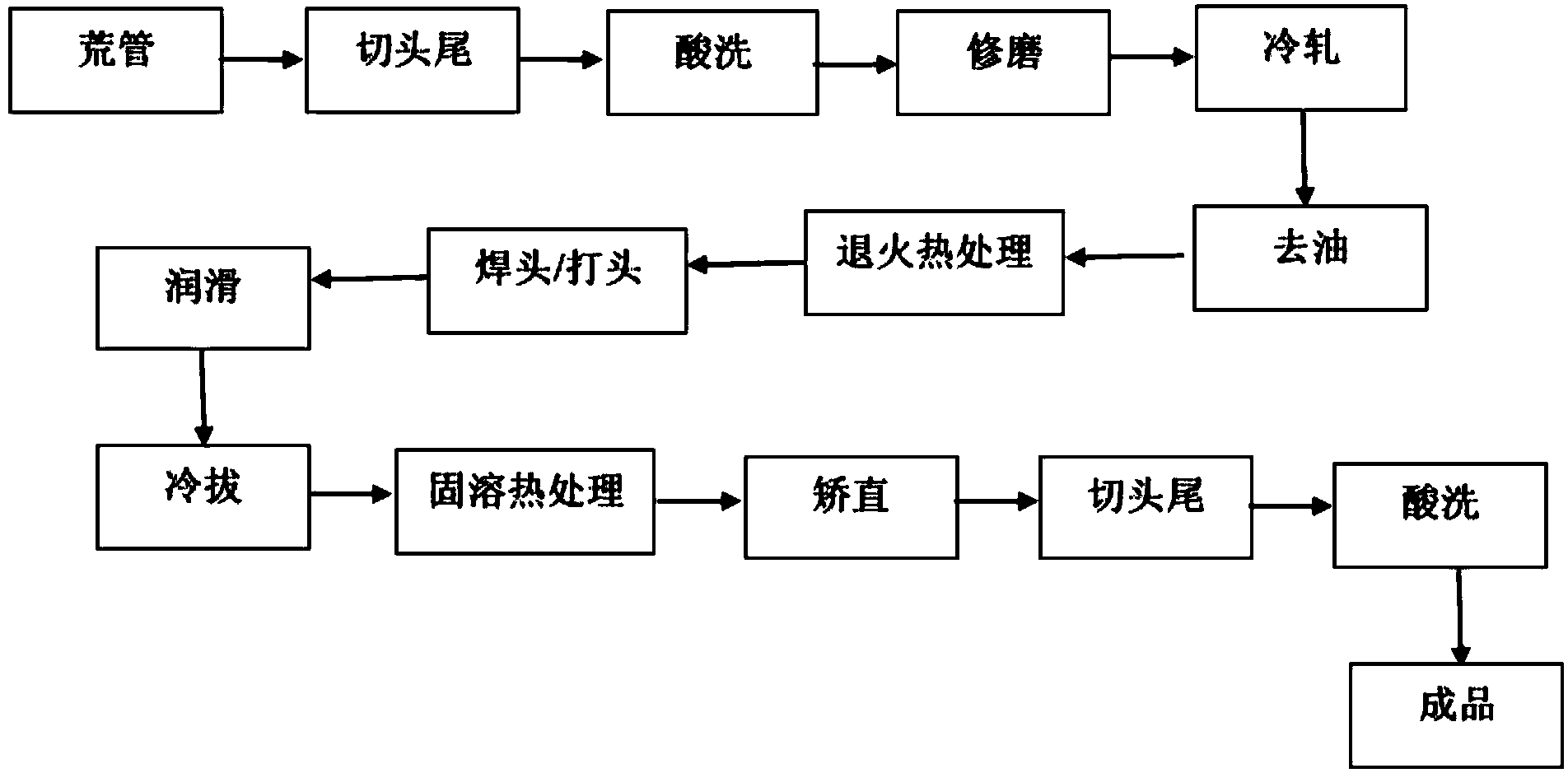

[0018] See figure 1 , The invention discloses a cold-drawn and cold-rolled mixed forming processing method for stainless steel seamless steel pipes, including the following steps:

[0019] 1) Prepare waste pipes and cut the ends of waste pipes;

[0020] 2) Carry out the first pickling of the blank tube blank;

[0021] 3) Grinding, cold rolling and degreasing the pickled blanks;

[0022] 4) Determine whether it meets the requirements of the finished product, and if so, perform annealing treatment;

[0023] 5) The weld head (heading) of the annealed semi-finished steel pipe is lubricated and cold drawn;

[0024] 6) Carry out solution heat treatment, straightening and fixed cutting of finished products;

[0025] 7) Pickling the finished product;

[0026] 8) Finished product inspection steps: The finished product inspection includes surface inspection, hydraulic testing, eddy current flaw detection, ultrasonic flaw detection, intergranular corrosion test, grain size test, tensile test, flarin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com