Hybrid power device and system with fuel and direct-injection liquid gas and power output construction method

A hybrid system, liquid gas technology, applied in combustion engines, internal combustion piston engines, engine components, etc., can solve the problems of smoke and dust particles polluting the environment, the recycling rate is only 9%, and the consumption is large, so as to overcome the heat loss problem. , The effect of avoiding icing and reducing fuel consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

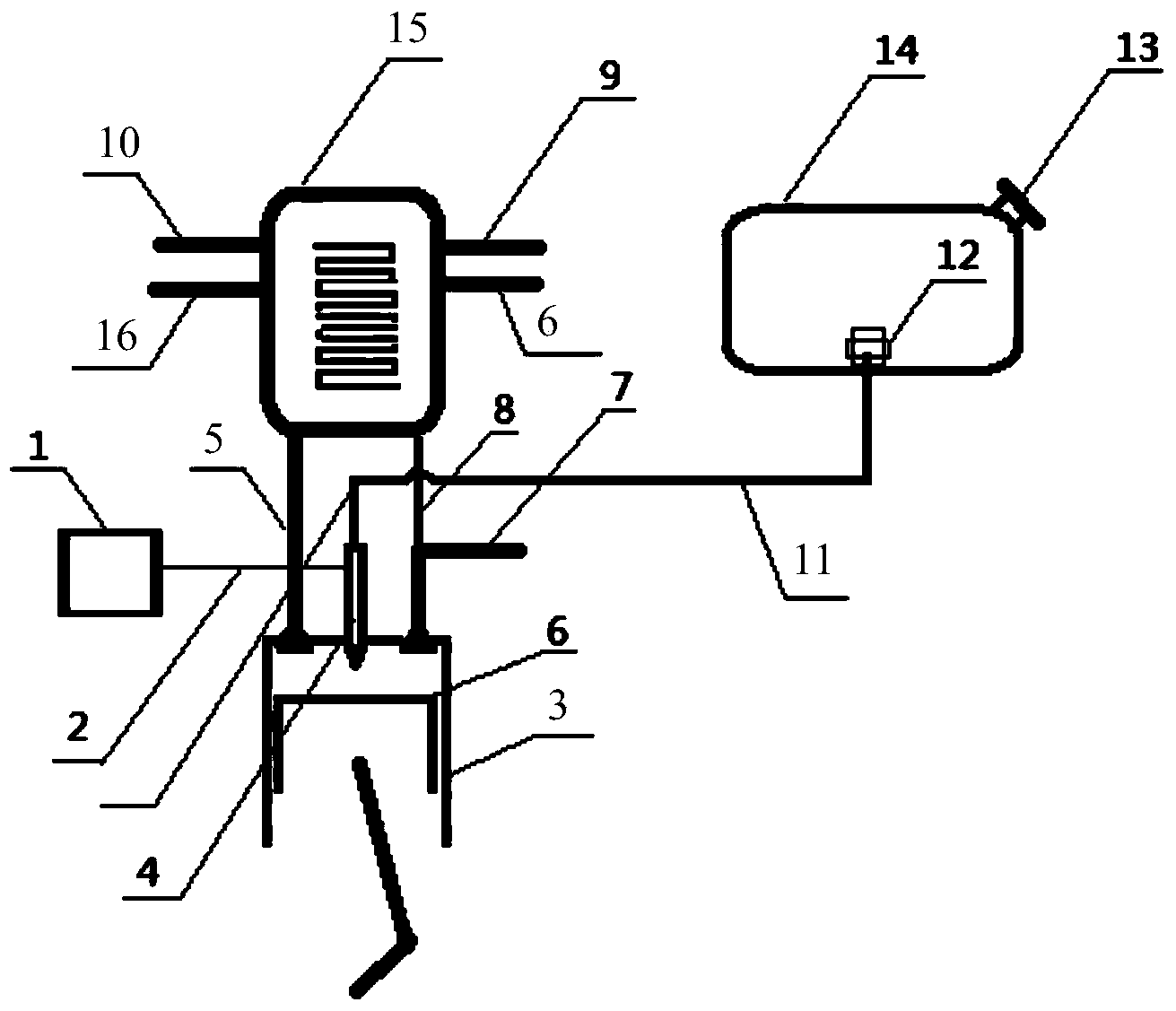

[0041] The core of the present invention is to provide a hybrid power output construction method using fuel and direct injection liquid gas, and a hybrid power system using fuel and direct injection liquid gas applying the concept. The application of the invention can fully improve energy utilization rate on the basis of energy saving and emission reduction. The present embodiment will be described in detail below in conjunction with the accompanying drawings.

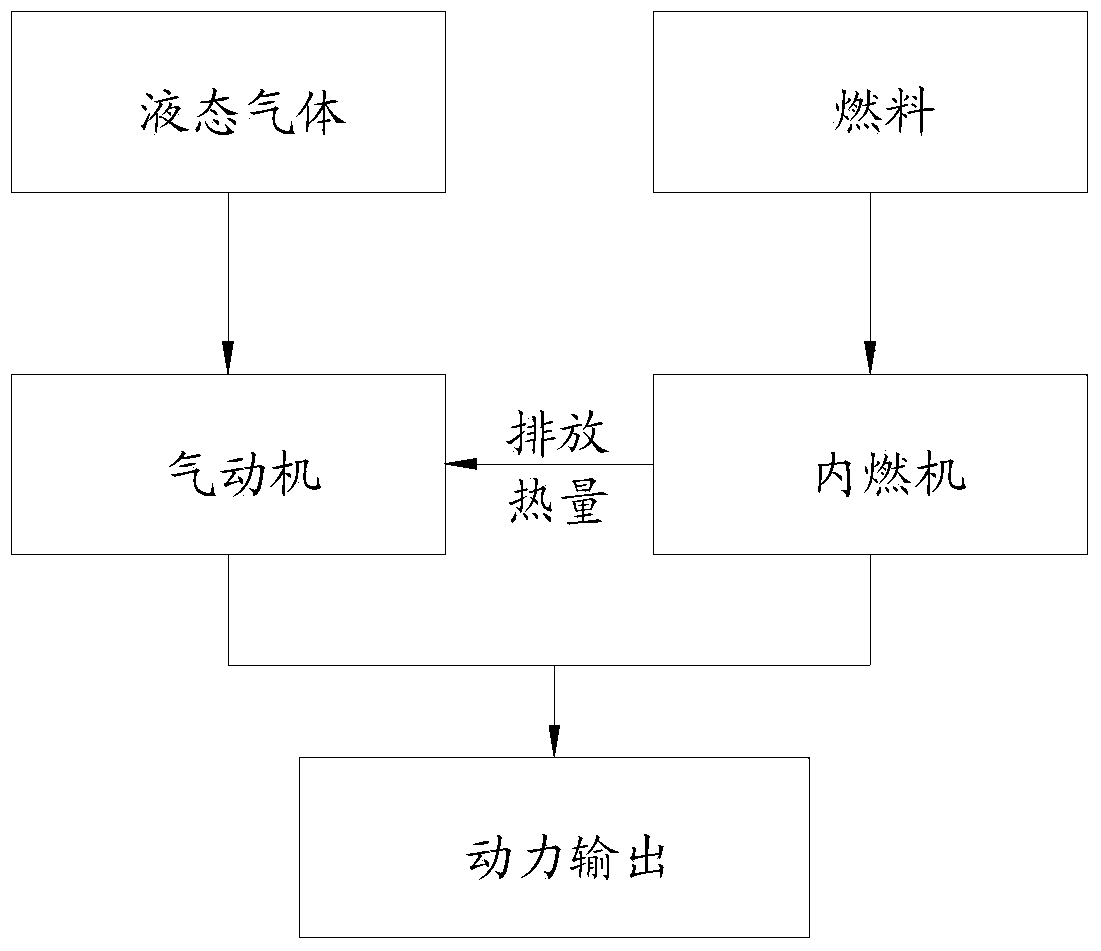

[0042] See figure 1 , which shows a functional block diagram of the construction method for realizing hybrid power output using fuel and direct injection of liquid gas according to this embodiment.

[0043] As shown in the figure, the hybrid power output construction method using fuel and direct injection liquid gas uses liquid gas and fuel as the basic source of driving force, in which the pressure formed by the expansion of liquid gas when heated and the work done by fuel combustion The pressure formed together ser...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com